Resin-rubber composite special-shaped body

A technology of resin rubber and special-shaped body, which is applied in drilling composition, earthwork drilling, wellbore/well components, etc., can solve the problems of bridging particles, such as insufficient temperature resistance, insufficient compression resistance, and low leakage plugging success rate. , to achieve the effect of improving the success rate of leak plugging, not easy to flow back, strong resistance to temperature and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0041] Weigh 600g of resin molding agent (thermosetting phenolic resin: thermoplastic phenolic resin: polypropylene = 5:1:1) + hexamethylenetetramine 10g + 1-5mm glass fiber 60g + density regulator 100g (limestone powder: aluminum powder =8:2)+50g of polypropylene grafted with maleic anhydride, and mix it evenly, add it into the kneader, heat the equipment to 180-200°C for kneading, start the extrusion equipment and start pouring into the mold (side length 5mm triangular cone) for extrusion injection, after the mold is cooled, take out the plugging particle product from the mold; by adjusting the amount of density regulator to prepare plugging particles with different densities, it can ensure that the plugging particles have different densities in drilling fluids All have good suspension stability.

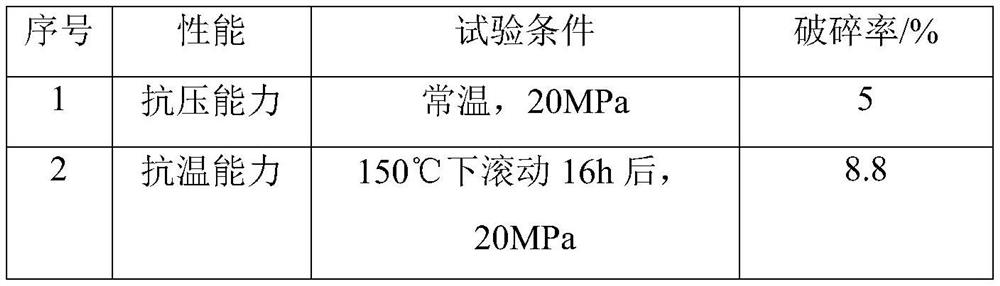

[0042] Resin-rubber compound special-shaped property evaluation method of the present invention:

[0043] (1) Evaluation of compression resistance: Weigh 200g of plugging particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com