Multi-equipment efficient construction method of automatic pile body non-squeezing soil type carrier pile

A construction method and technology of carrier piles, applied in sheet pile walls, soil protection, infrastructure engineering, etc., can solve the problems of ramming equipment affecting construction efficiency, achieve control of manufacturing costs and maintenance difficulties, reduce labor costs and construction The effect of cost and easy calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

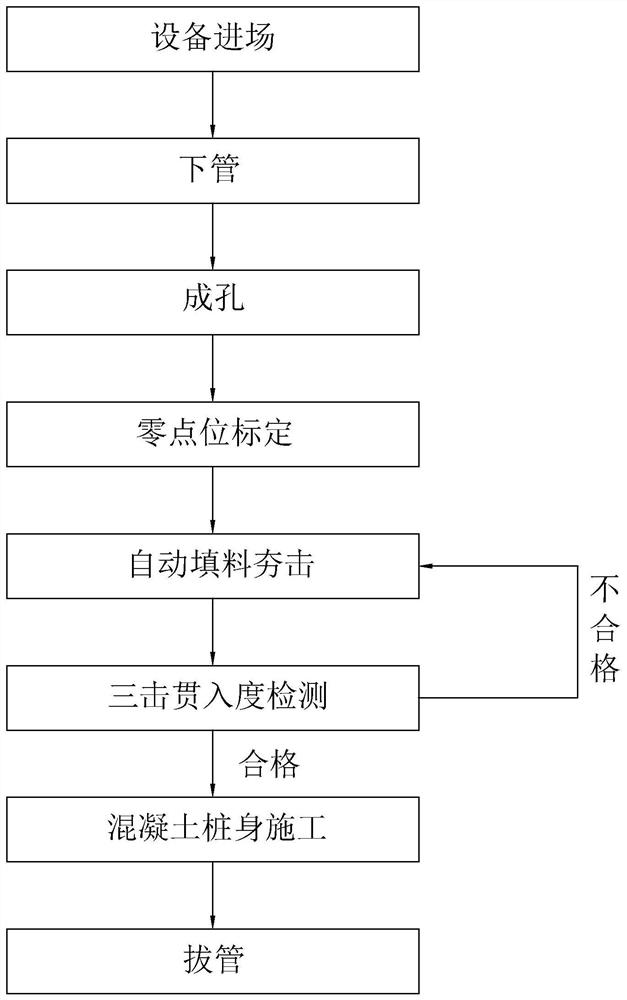

[0053] The embodiment of the present application discloses an efficient multi-equipment construction method for an automated pile body non-squeezing soil type carrier pile. refer to figure 1 and figure 2 , the multi-equipment efficient construction method of the automatic pile body non-squeezing soil type carrier pile includes the following steps:

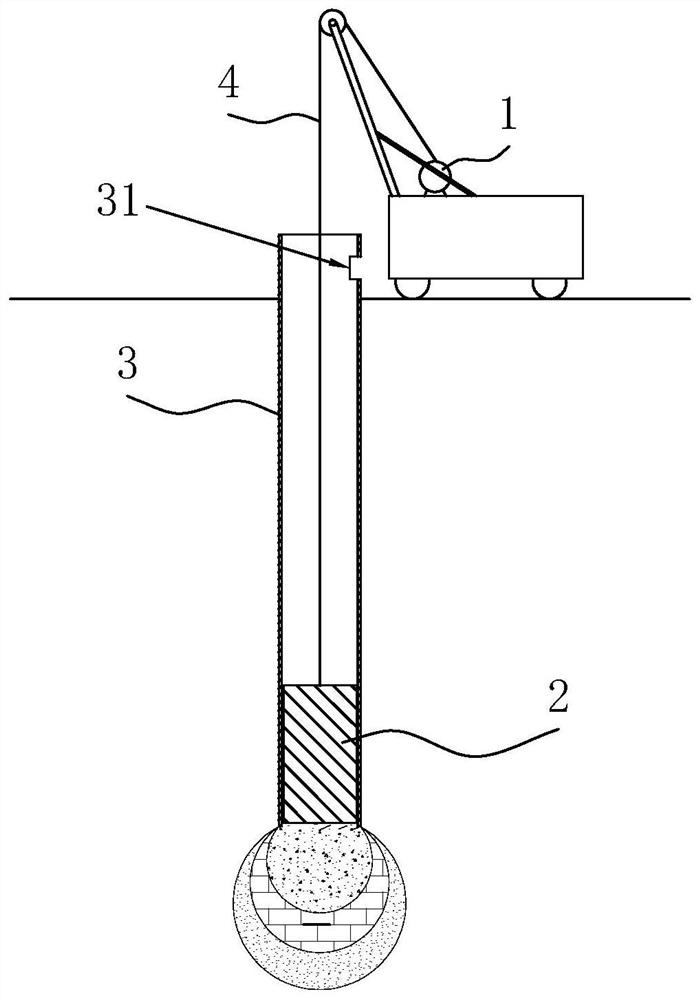

[0054] S1. When the equipment enters the site, prepare cranes, vibratory hammers, hydraulic clamps, hydraulic hoists 1, rammers 2, steel casings 3 and packing conveying devices at the construction site. In the construction site of large quantities of compressive carrier piles, the above construction equipment Prepare a plurality of them, wind the suspension rope 4 on the hydraulic winch 1, install the rammer 2 on the hook at the end of the suspension rope 4 for tamping the packing, install the hydraulic clamp on the end of the steel casing 3 and The vibratory hammer is installed on the crane for sinking the steel casing 3 , and ...

Embodiment 2

[0074] The embodiment of the present application discloses an efficient multi-equipment construction method for an automated pile body non-squeezing type carrier pile. 2's vertical height or the altitude above sea level is marked, and during actual calibration, a GPS instrument connected with computer information is installed on the upper end of the rammer 2. The method of marking the zero point is: lower the rammer 2 to the bottom of the pit before ramming, calibrate the vertical height or altitude of the rammer 2 through the GPS instrument, and set the vertical height or altitude as the zero point of the rammer 2 .

[0075] The method for measuring the sinking depth is: after lowering the rammer 2 during tamping, measure and calculate the vertical height or altitude of the rammer 2 at this time through the GPS instrument, and subtract it from the vertical height or altitude of the rammer 2 at the zero point The calculated vertical height or altitude can be used to obtain th...

Embodiment 3

[0080] The embodiment of the present application discloses an efficient multi-equipment construction method for an automated pile body non-squeezing soil-type carrier pile. Cylinder 3, specifically, since the steel casing 3 generally has a wall thickness of 15-30 mm, a small static pile machine is used to statically press the steel casing 3 to the design elevation. When the static pressure method is selected to sink the steel casing 3, the vibration of the surrounding soil is less affected, which effectively ensures the stability among multiple compressive carrier piles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com