Full-automatic concrete vibration surface finishing device

A concrete, fully automatic technology, applied in construction, infrastructure engineering and other directions, can solve problems such as affecting the hardness of concrete, consuming a lot of manpower and material resources, and insufficient vibration, saving labor and material costs, improving elevation control, and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

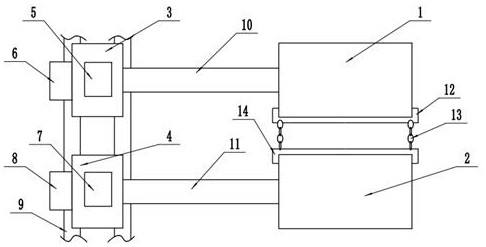

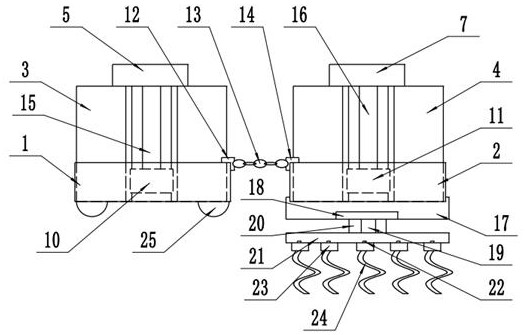

[0038] This example: see figure 1 and figure 2 , full-automatic concrete vibrating surface-receiving device, including a surface-receiving mechanism and a vibrating mechanism softly connected with the surface-receiving mechanism. The surface-receiving mechanism and the vibrating mechanism are arranged vertically side by side, and can run along the width of the concrete on the ground. The surface-receiving mechanism includes a self-propelled The first traveling unit 3 and the receiving panel 1, the first longitudinal cylinder 5 is arranged above the first traveling unit 3, the first transverse cylinder 6 is provided on the side of the first traveling unit 3, and the receiving panel 1 is arranged on the first traveling unit 3 The connected first telescopic rod 10, the first slideway that the first walking unit 3 is provided with along its height direction, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com