Waterproof and wind-resistant structure for roof cornice of transformer substation

A technology for substations and waterproof devices, which is applied to roofs, substations, roof drainage, etc., can solve problems such as sealant sealing failure and water leakage, and achieve the effects of convenient installation, simple structure, and improved waterproofing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

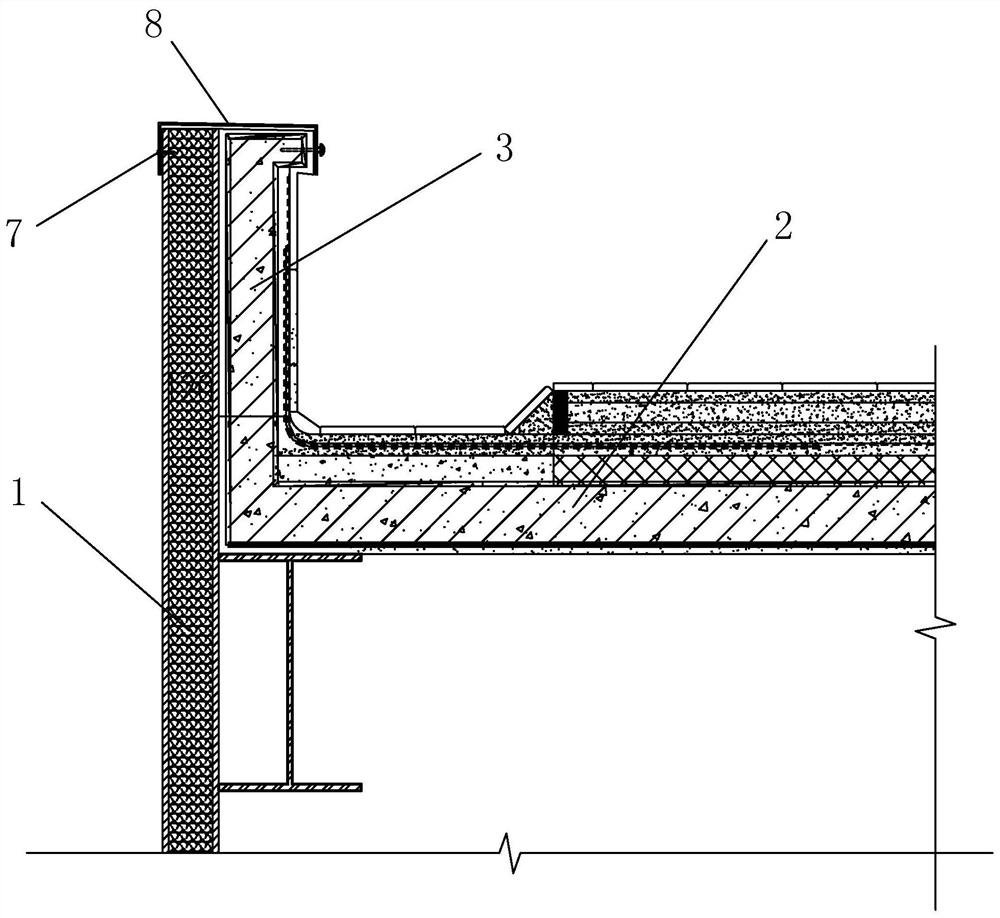

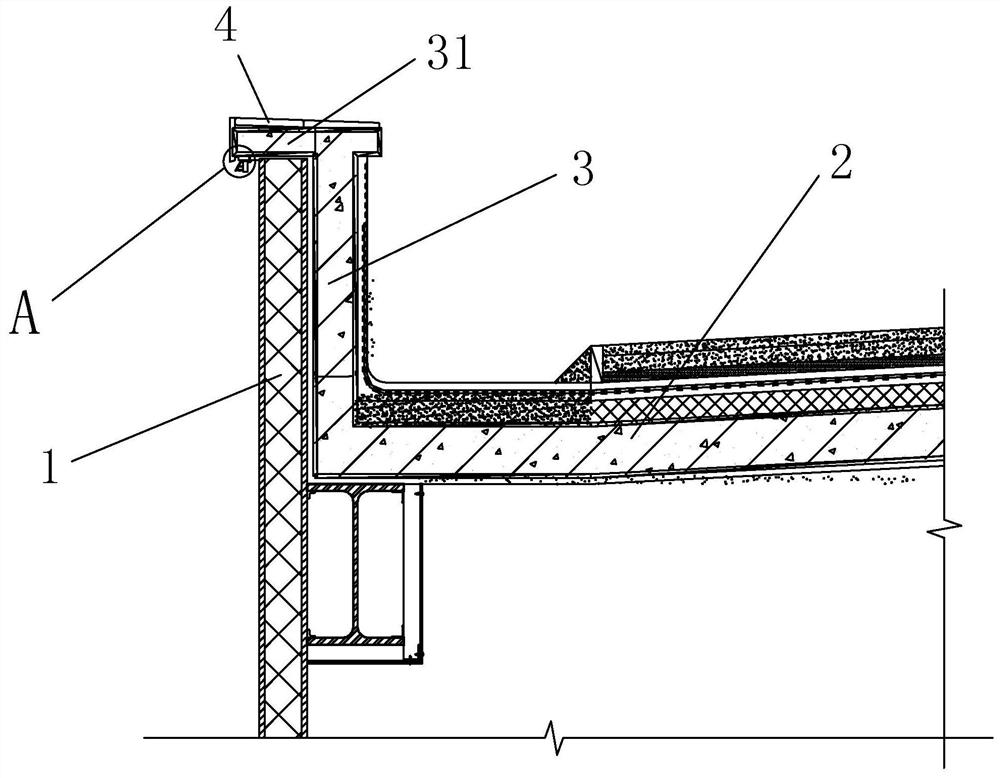

[0021] Such as figure 2 As shown, a substation roof eaves waterproof and wind-resistant structure includes a parapet 3 arranged on the roof 2 and an outer wall panel 1 arranged on the outer wall of the roof 2. The upper end of the parapet 3 is higher than the outer wall panel 1 and faces the outer wall. An extension part 31 is extended in the direction of the board 1, and the side of the extension part 31 away from the parapet 3 exceeds the outer wall of the exterior wall panel 1. The bottom of the extension part 31 is provided with a drip line groove 32. The design of the extension part 31 can play The effect of keeping out the rain and waterproofing, the setting of the drip line groove 32 can make the rainwater drip down after being collected at the drip line groove 32 in rainy days, so that the rainwater at this place will not contact the wallboard, thereby preventing the situation of water leakage.

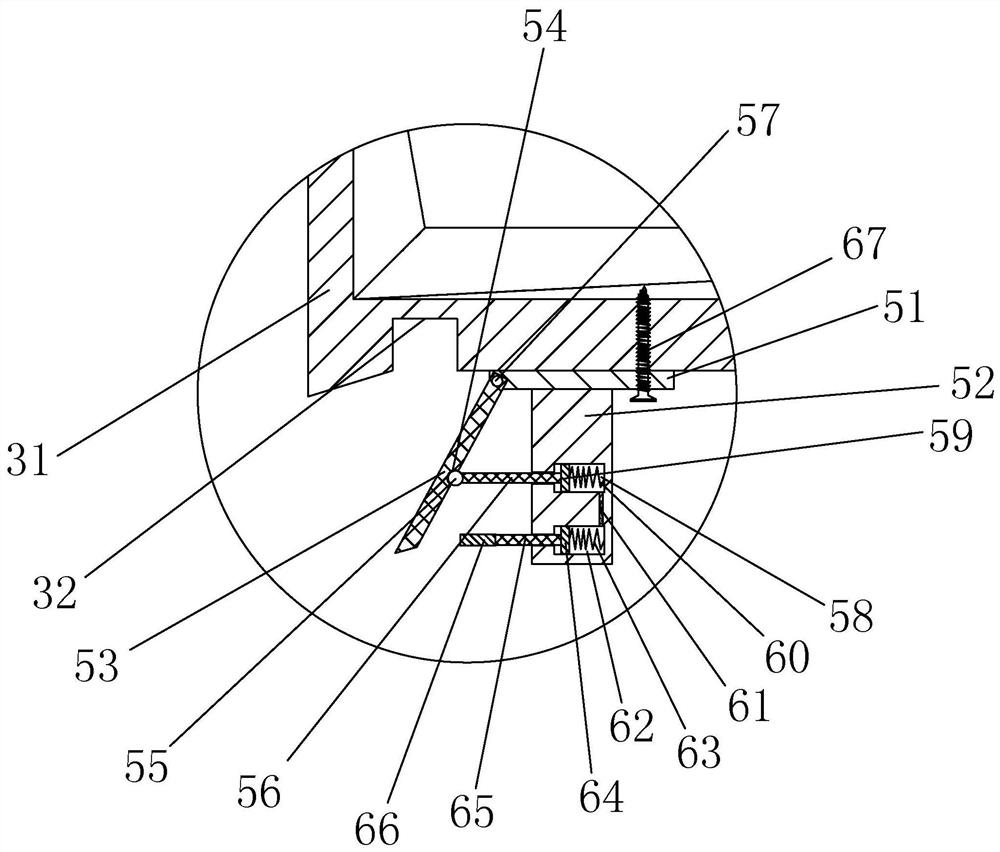

[0022] The top of the parapet wall 3 is provided with a windproof roof t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com