Fireproof corrosion-resistant shock insulation support

A shock-isolation bearing and corrosion-resistant technology, which is applied in the direction of earthquake resistance, fire prevention, and building components, etc., can solve problems such as cracking of paint, no sealing performance, and poor performance of the fireproof ability of the fire cover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

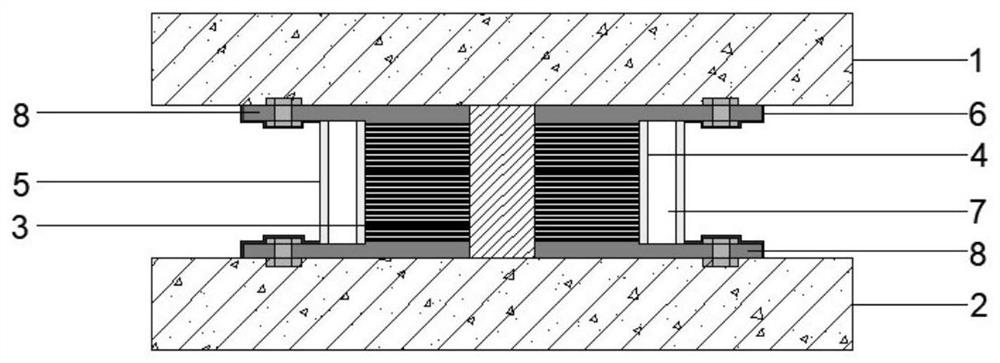

Embodiment 1

[0031] see figure 1 , the technical solution provided by the present invention is: a fire-proof, corrosion-resistant and shock-isolation bearing comprising: an upper structure bearing platform 1, a lower foundation bearing platform 2, a fireproof coating 3, bolts 4, double-layer fireproof rubber 6, lead core laminated rubber Bearing 7, wherein, the double-layer fireproof rubber 6 on the outside of the lead core laminated rubber bearing 7 body is a hollow annular cylinder, which is enveloped on the periphery of the rubber bearing 7 body, and the lead core laminated rubber bearing 7 The outer covering rubber and the rubber layer on the outside of the outer covering rubber are all fire-resistant rubber; on the upper and lower sides of the lead core laminated rubber bearing 7 body, the steel surface is also coated with fire-resistant paint 3. Under the premise of providing a certain fire-proof ability, the hollow double-layer Fireproof rubber 6 will not affect the horizontal defor...

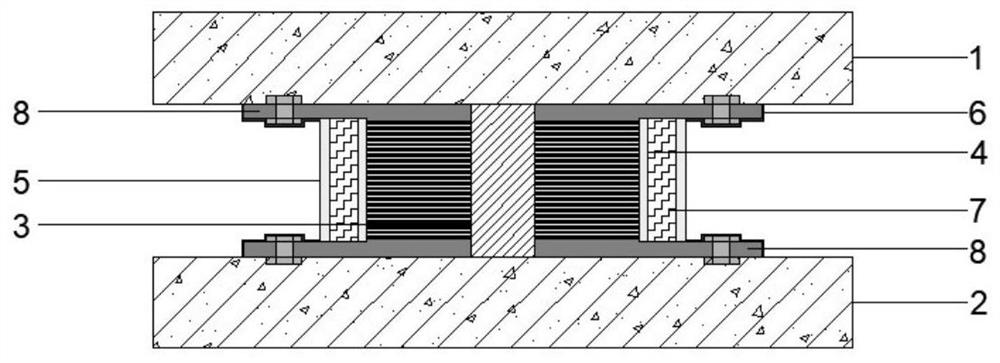

Embodiment 2

[0033] see figure 2 , on the basis of Embodiment 1, this embodiment also includes the following content, the flexible material 5 is filled in the hollow double-layer fireproof rubber 6, and the flexible material 5 is asbestos, because the double-layer fireproof rubber 6 only serves as the first fireproof The layer does not need a very large thickness, and has no effect on the horizontal deformation capacity of the lead core laminated rubber bearing 7; the cavity inside the double-layer fireproof rubber 6 is filled with a flexible fireproof material 5, such as asbestos, as the second fireproof layer, Provide adequate fire resistance.

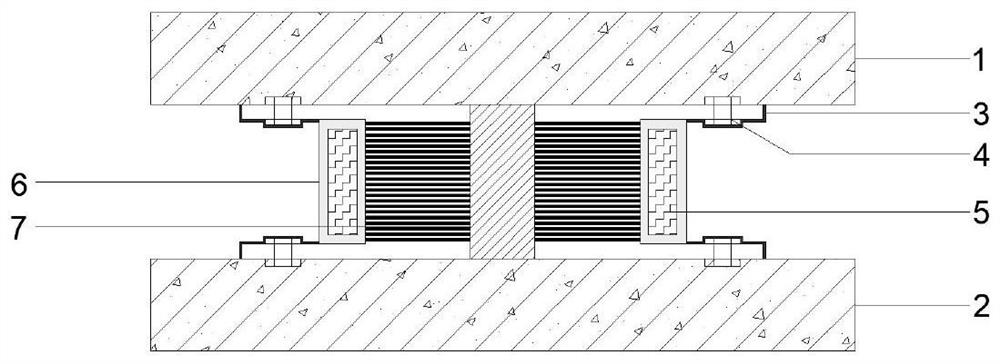

Embodiment 3

[0035] see image 3 , on the basis of Embodiment 2, this embodiment also includes the following content: the top and bottom of the double-layer fireproof rubber 6 are set to be connected to form a hollow ring-shaped cylinder with a closed outer surface, and the interior is filled with flexible fireproof materials 5, such as asbestos, when using the vulcanization process to connect the double-layer fire-resistant rubber 6 and the lead-core laminated rubber bearing 7 body, the design of the top and bottom connection can make the double-layer fire-resistant rubber 6 and the lead-core laminated rubber bearing The connection of 7 is tighter and the sealing performance is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com