Vortex type device for separating petroleum drilling rock core from rock debris

An oil drilling and vortex technology, applied in the field of oil drilling, can solve the problems of reducing the value of core and cuttings, taking a long time, and not being able to completely separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

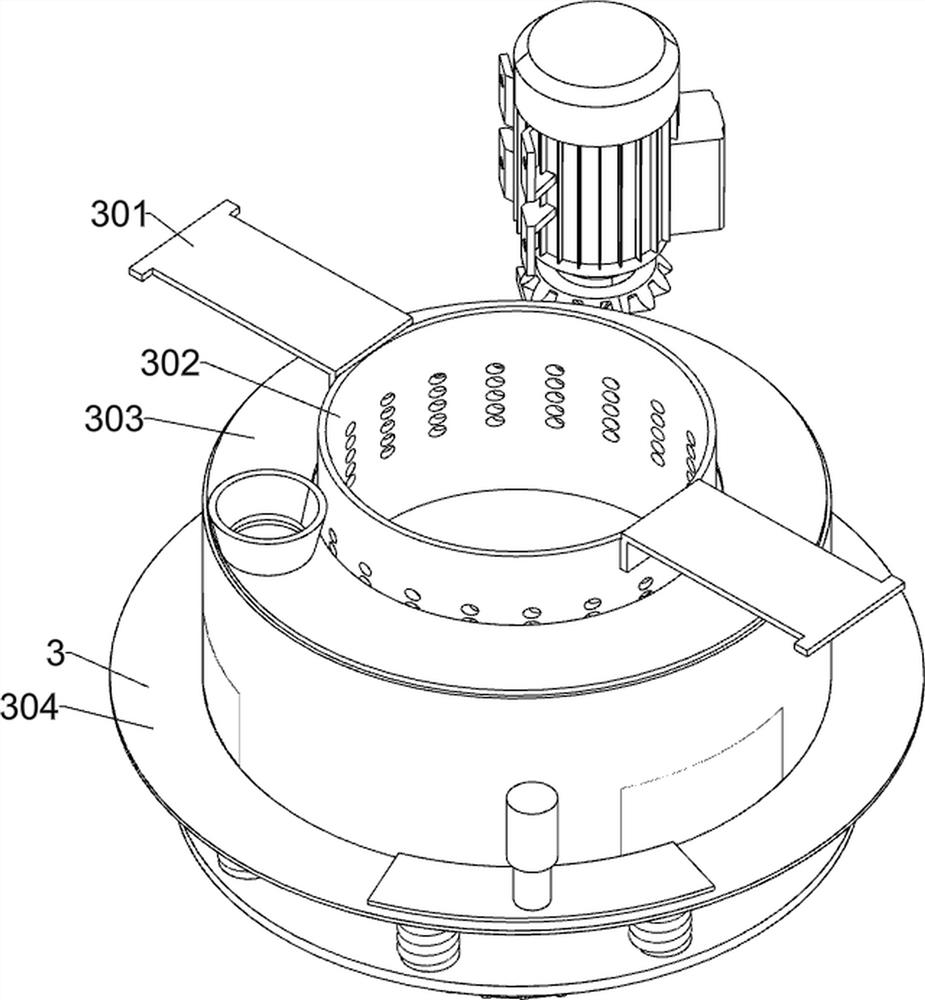

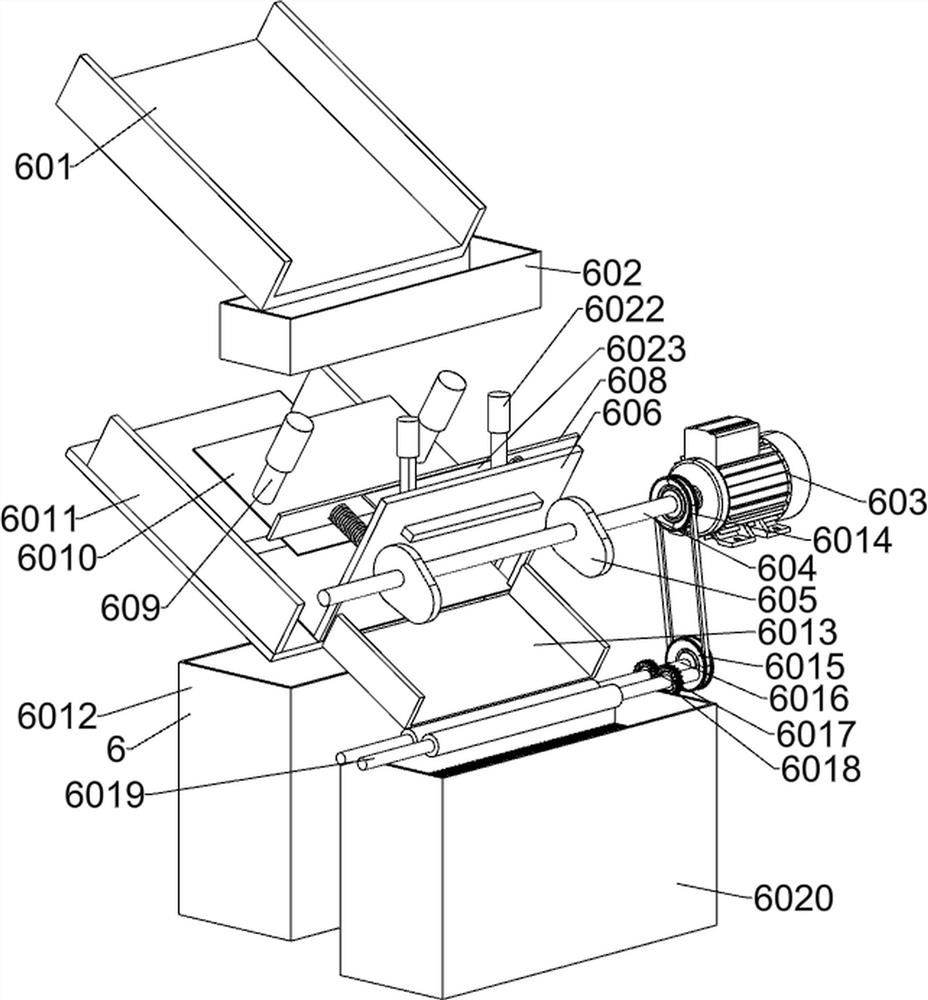

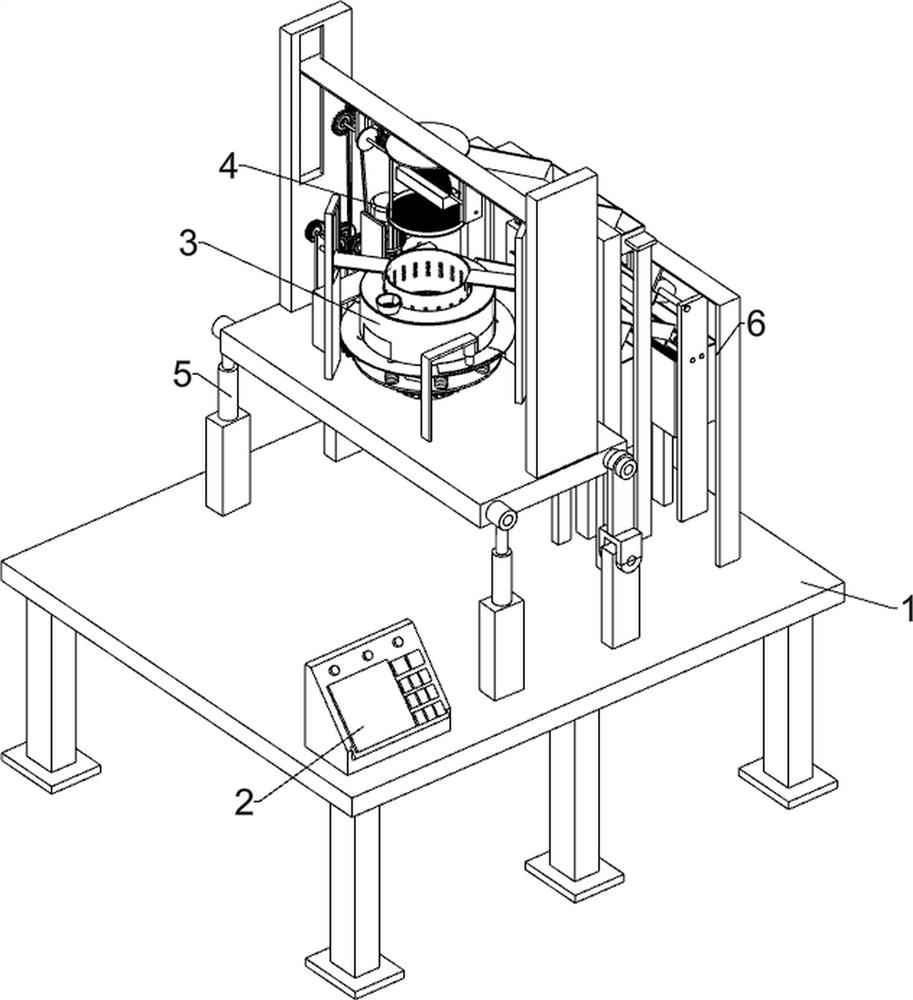

[0035] A device for vortex separation of oil drilling core and cuttings, such as Figure 1-13 As shown, it includes a fixed frame 1, a controller 2, a vortex traction mechanism 3, a separation mechanism 4, a tilting mechanism 5 and a solidification and cutting mechanism 6; the fixed frame 1 is connected with the controller 2; the fixed frame 1 and the tilting mechanism 5 The fixed frame 1 is connected with the solidification cutting mechanism 6; the vortex traction mechanism 3 is connected with the separation mechanism 4; the vortex traction mechanism 3 is connected with the tilting mechanism 5;

[0036] Working principle: Before starting work, the device is first fixed stably by the fixing frame 1, and then a certain amount of core and cuttings obtained from oil drilling are manually poured into the vortex traction mechanism 3, and then an appropriate amount of water is poured into the vortex traction mechanism 3. In the traction mechanism 3, an external power supply is then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com