Preparation method of super-junction MOSFET

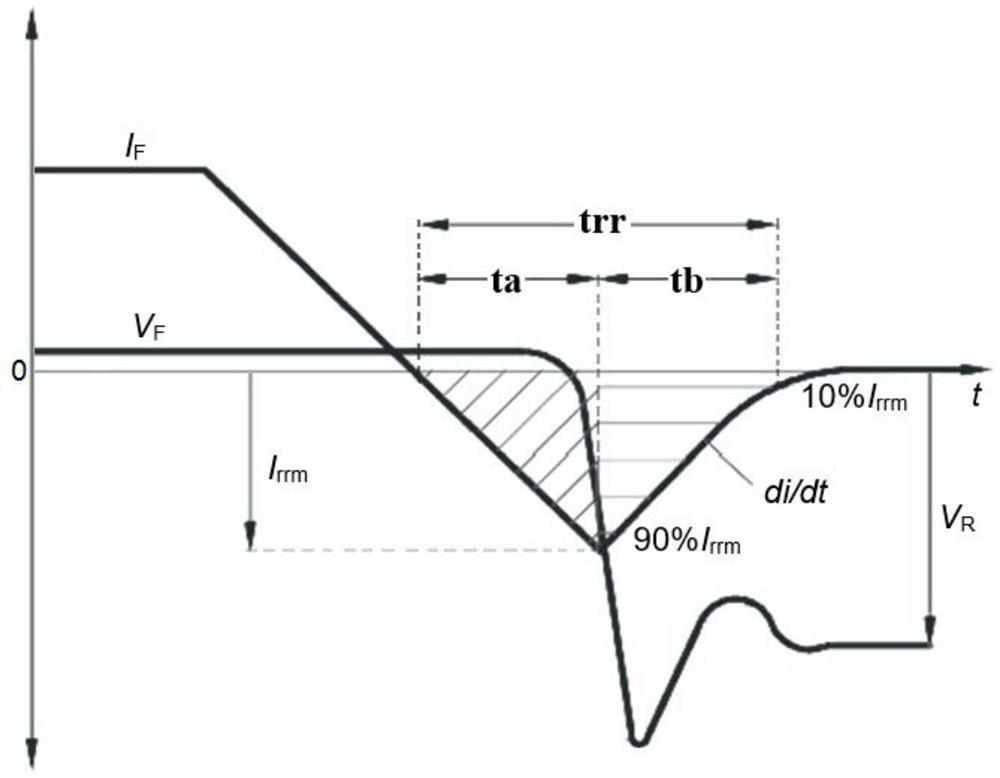

A one-sided, N-type technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem that reverse recovery characteristics cannot meet the needs of superjunction MOSFETs, and achieve fast recovery characteristics and improve reverse recovery. Speed, effect of reducing total time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions in the embodiments of the present application will be clearly described below in conjunction with the accompanying drawings. In the case of no conflict, the following embodiments and their technical features can be combined with each other.

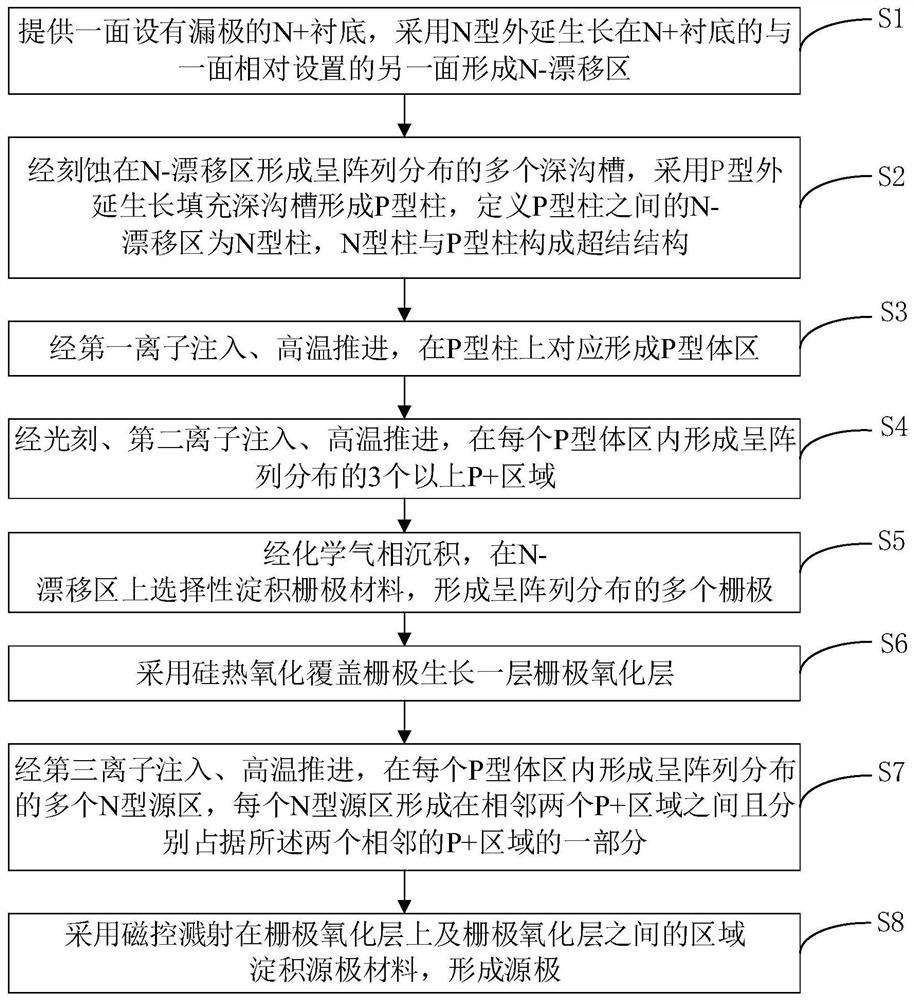

[0046] see image 3 , an embodiment of a method for manufacturing a super junction MOSFET provided by the present application, the method includes the following steps S1-S8.

[0047] Please also refer to Figure 4 to Figure 10 , S1, providing an N+ substrate 2 with a drain 1 on one side 21, and forming an N-drift region 3 on the other side 22 of the N+ substrate 2 opposite to the one side 21 by N-type epitaxial growth.

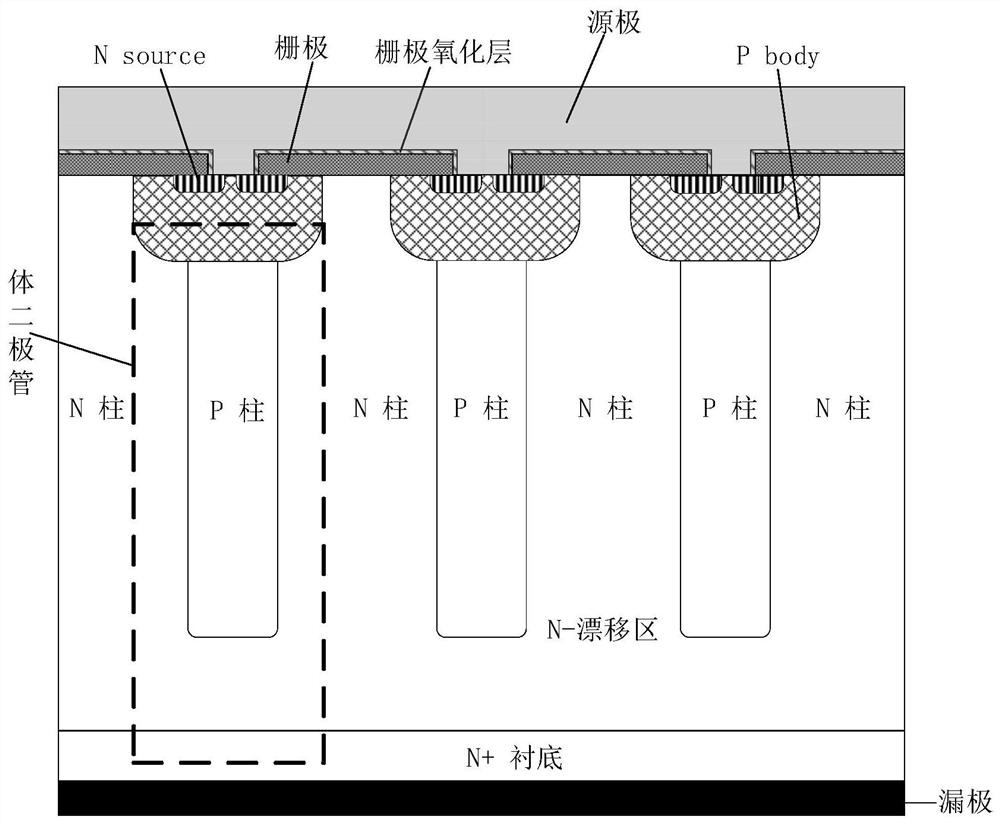

[0048] S2. A plurality of deep trenches distributed in an array are formed in the N-drift region 3 after etching, and P-type epitaxial growth is used to fill the deep trenches to form P-type pillars 32 to define the N-drift region 3 between the P-type pillars 32 It is an N-type column 33 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com