Multi-shovel plowing machine

A frame and crank technology, applied in the field of agricultural machinery and equipment, can solve problems such as unfavorable crop growth and development, unfavorable seed bed leveling, etc., and achieve the effects of favoring growth and development, reducing labor intensity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

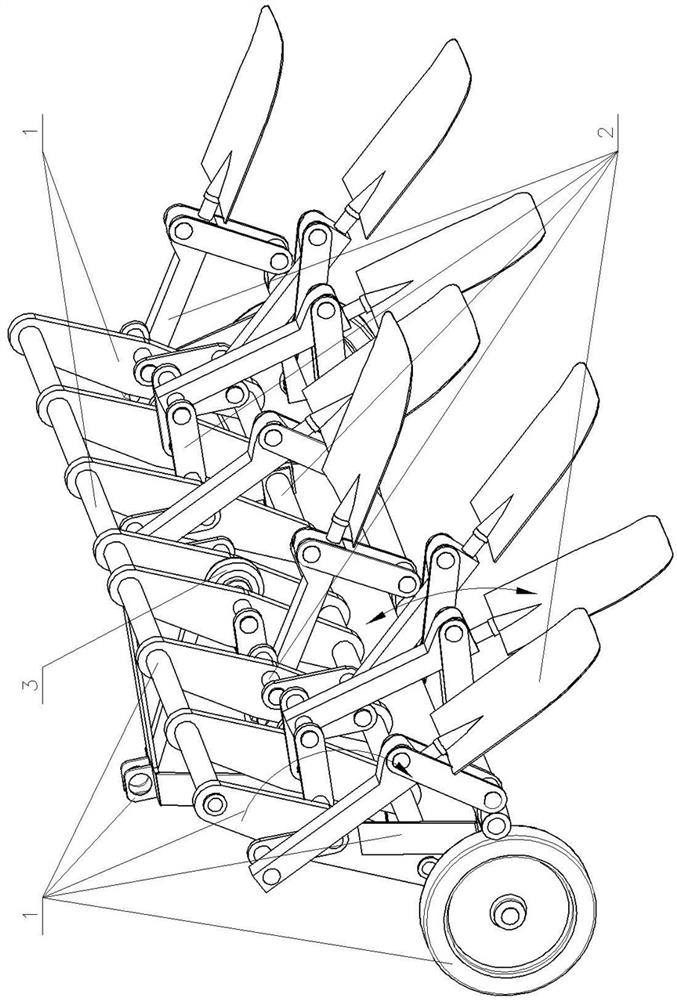

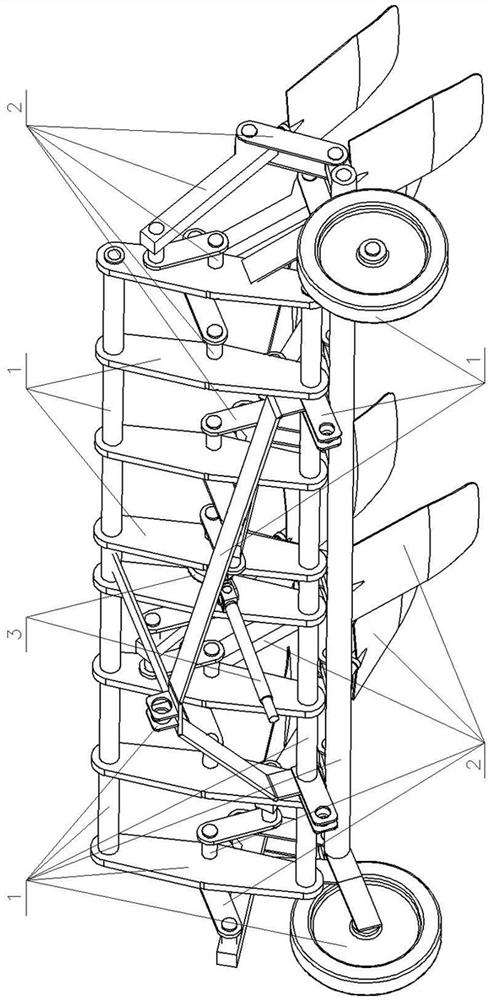

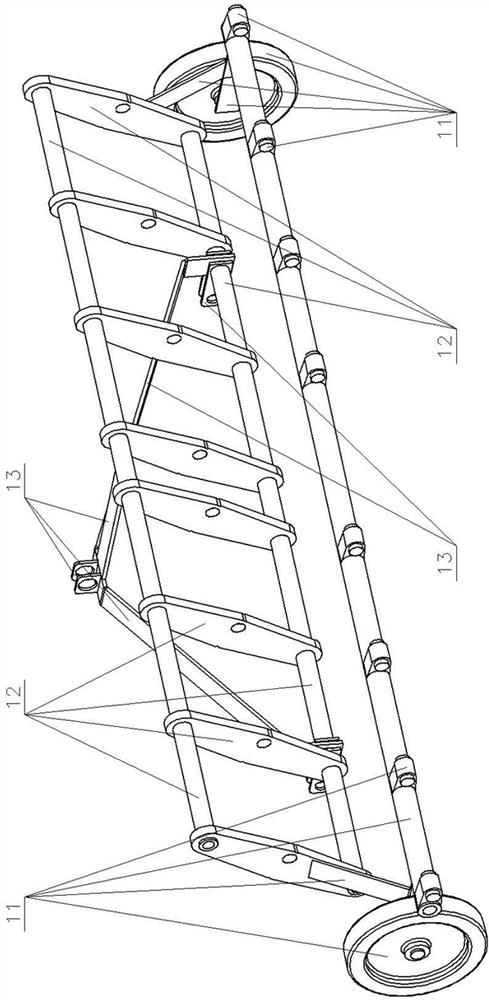

[0035] 1. Rack 11, bracket 111, support arm 112, beam 113, lug I 114, pin shaft I 115, support member 1151, outrigger I 1152, pin shaft II 1153, ground wheel 1154, outrigger II 1155, outrigger 12 , driving frame 121, link rod 122, driving plate 13, traction frame 131, herringbone frame 132, traction rod 133, lug II 134, lug III 2, turning mechanism 21, crankshaft 211, crank 212, center shaft Ⅰ 213, central shaft Ⅱ 214, drive shaft Ⅰ 215, drive shaft Ⅱ 22, rocker arm 221, rocker arm plate 23, ground turning shovel 231, connecting rod 232, spade handle 233, lug Ⅳ 234, symmetrical spade head 235, Left partial spade head 236, right partial spade head 3, driving device 31, speed reducer 32, universal joint 33, transmission shaft.

[0036] exist Figure 1-Figure 15 and Figure 17 In the shown embodiment: the support arms 111 of the support 11 of the frame 1 are in the shape of straight rods, and one ends of the two support arms 111 are symmetrically fixed on the two ends of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com