Novel sample filter

A filter and sample technology, applied in the field of experimental equipment, can solve problems such as high pressure on the hand, hand fatigue, pollution, etc., and achieve the effects of reducing experimental costs, reducing labor intensity, and avoiding cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

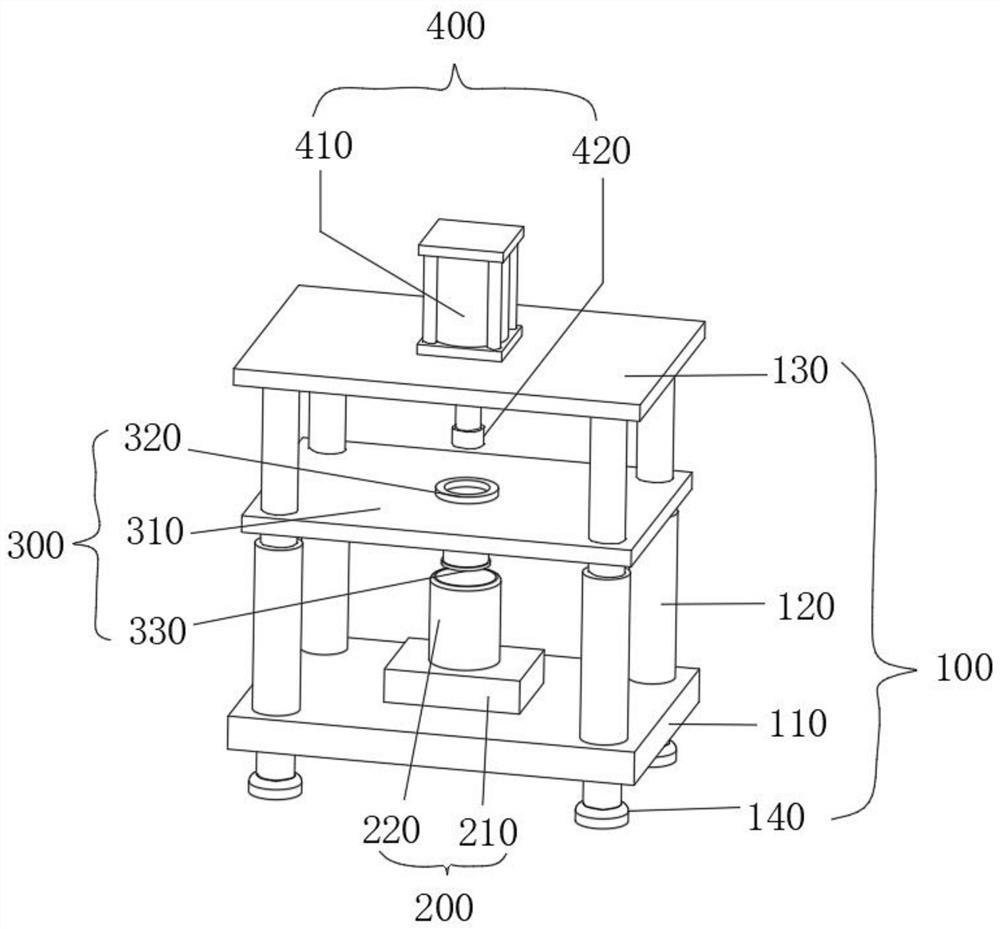

[0028] A novel sample filter comprising:

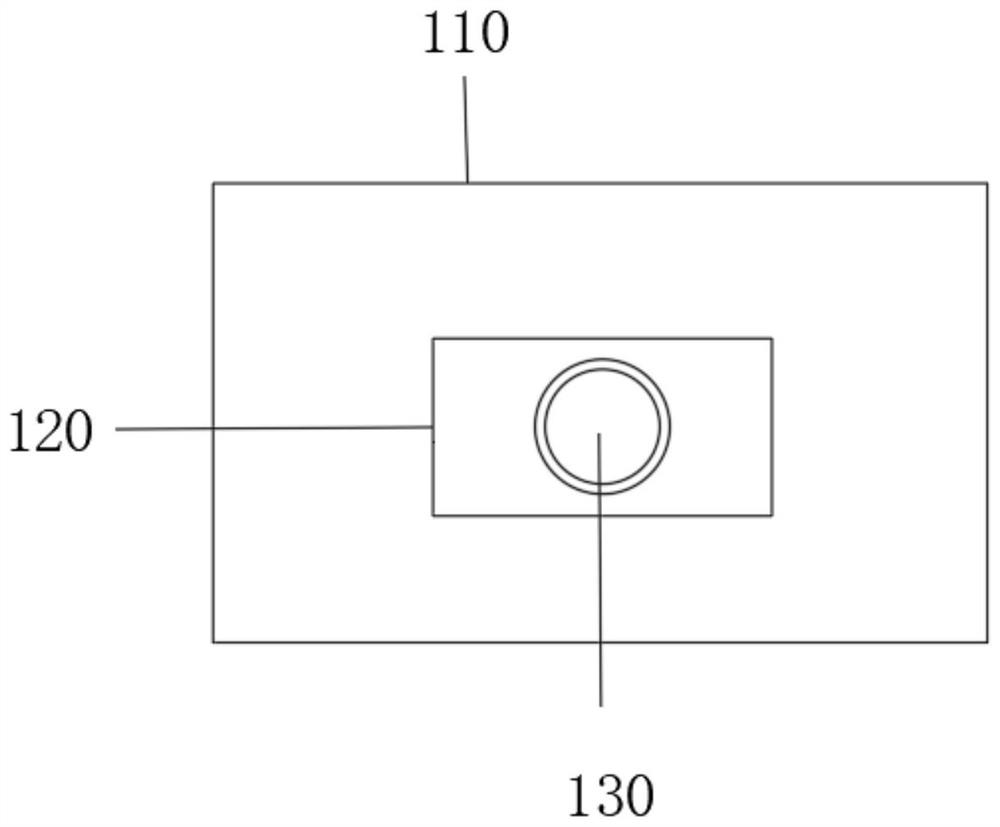

[0029] The frame 100, the frame 100 includes a base 110, the top four corners of the base 110 are provided with electric telescopic rods 120, and the top of the electric telescopic rods 120 is provided with a top seat 130;

[0030] The receiving assembly 200, the receiving assembly 200 includes a centrifuge tube base 210, the centrifuge tube base 210 is installed in the middle of the top of the base 110, and the top of the centrifuge tube base 210 is provided with a centrifuge tube body 220;

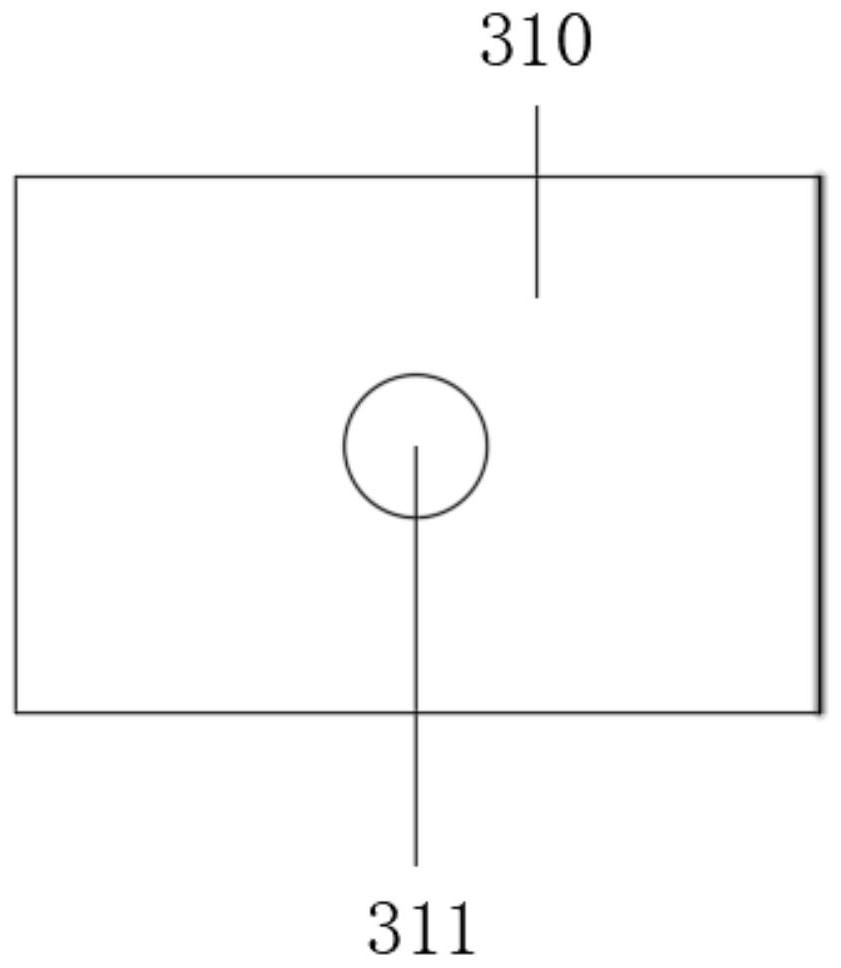

[0031] The fixed assembly 300, the fixed assembly 300 includes a loading board 310, the loading board 310 is installed between the electric telescopic rods 120, the syringe 320 is arranged on the loading board 310, and the bottom of the syringe 320 is provided with filter membrane 330;

[0032] The drive assembly 400 , the drive assembly 400 includes a cylinder 410 installed in the middle of the top of the top base 130 , and the bottom output e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com