Reciprocating type uniform cut-off mechanism for aluminum alloy handrail production

A cutting mechanism, reciprocating technology, applied in shearing devices, metal processing equipment, accessories of shearing machines, etc., can solve the problems of low comprehensive cost, low cutting efficiency of railings, high working intensity, etc., to avoid cutting failure, The effect of increasing the use range and increasing the placement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

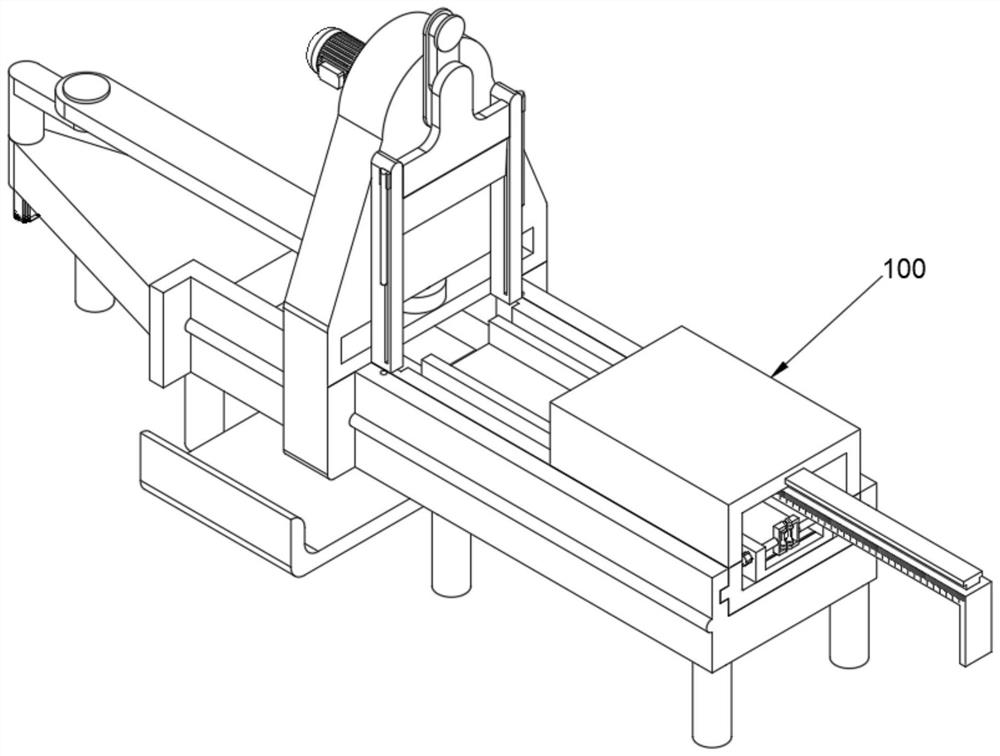

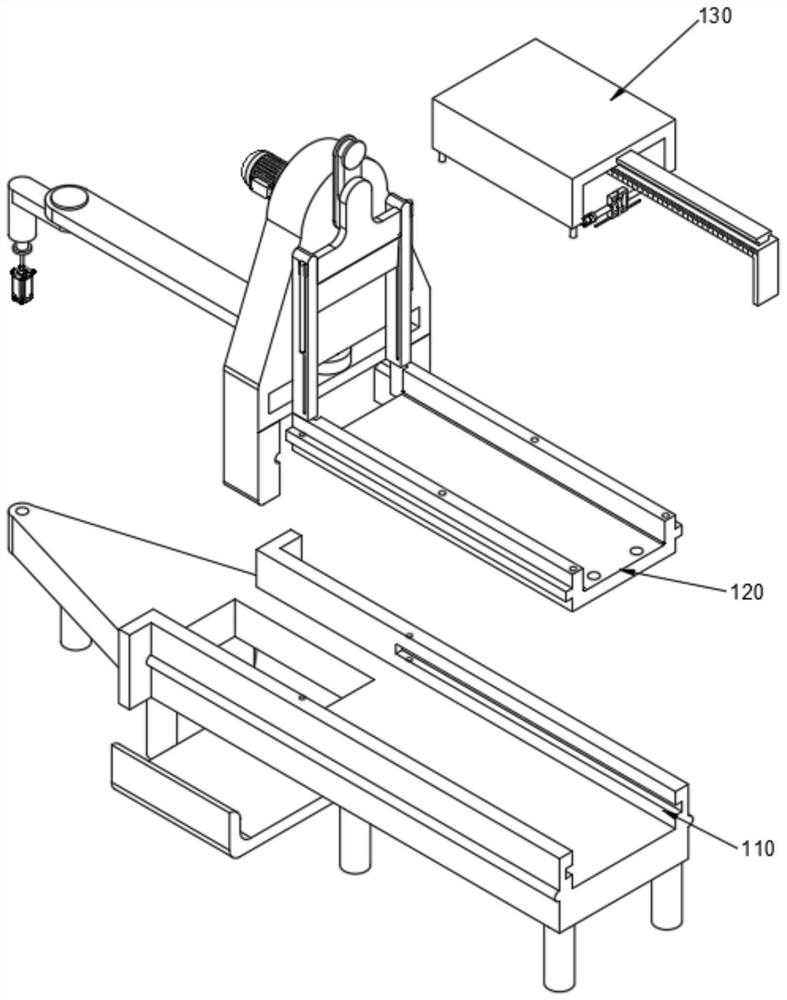

[0042] see Figure 1-Figure 8 As shown, the purpose of this embodiment is to provide a reciprocating-based uniform cutting mechanism for the production of aluminum alloy railings, including a cutting machine 100, and the cutting machine 100 includes at least:

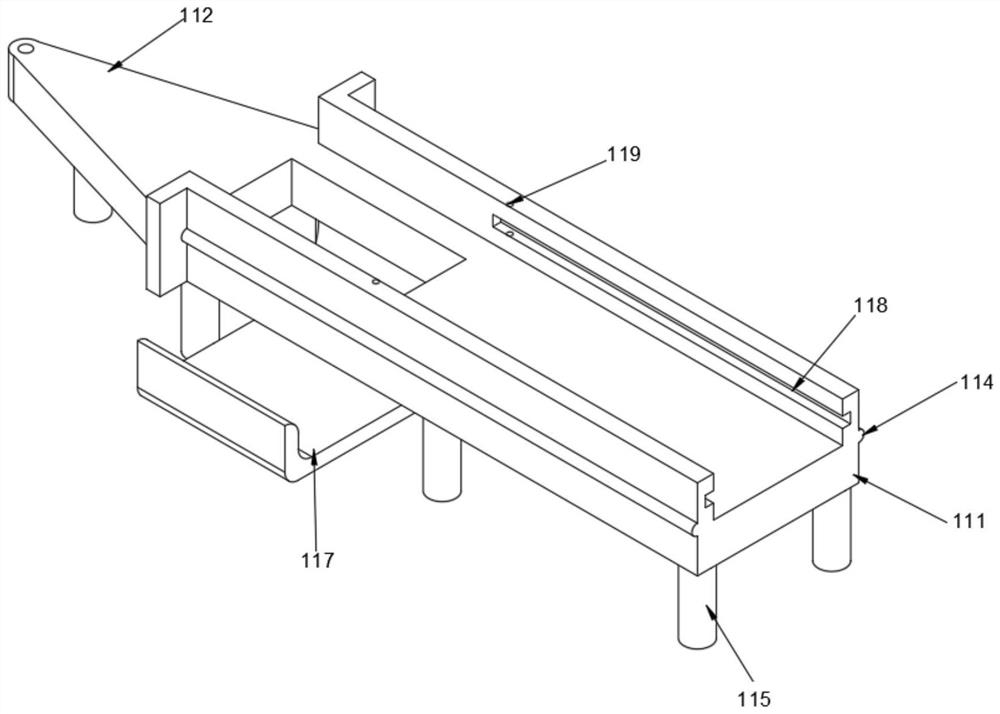

[0043] Mounting bracket 110, mounting bracket 110 includes No. 1 board 111, No. 1 board 111 is connected with No. 2 board 112, No. 1 board 111, No. The No. 1 rotating groove 113, the No. 1 rotating groove 113 is a "ten"-shaped cylindrical structure groove, the surface of the No. 1 plate 111 is correspondingly provided with a No. 1 sliding body 114, and the No. 1 sliding body 114 is a semi-cylindrical structure protrusion;

[0044]The power cutting body 120, the power cutting body 120 includes the No. 1 reciprocating body 121 located in the No. 1 rotating groove 113, the No. 1 reciprocating body 121 is connected with the No. 2 reciprocating body 122, and the bottom of the No. 2 reciprocating body 122 is provided with a N...

Embodiment 2

[0052] see Figure 9-Figure 11 As shown, while realizing the reciprocating cutting of the railing, the railings of different sizes can be cut and the length can be controlled. On the basis of embodiment 1, the following improvements are made:

[0053] Wherein, the adjustment body 130 includes a contact body 131, the contact body 131 includes a rotating connector 133, the railing fixed body 129 is provided with an adjustment groove 1291 penetrating through its surface, the rotating connector 133 is rotationally connected with the adjustment groove 1291, and the railing fixed body 129 The surface is provided with a No. 4 sliding groove 1292, and the No. 4 sliding groove 1292 is a "concave" groove structure. The rotating connecting body 133 is rotatably connected to an intermediate screw 134, and the intermediate screw 134 is rotatably connected to a railing extruding body 135, which is rotatably connected to a railing extruding body 135. The bottom is slidably connected to the N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com