Pedal feeling simulator assembly and brake system

A technology of simulators and pedals, applied in the direction of brake control system, brake system interaction, brakes, etc., can solve problems such as driver confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

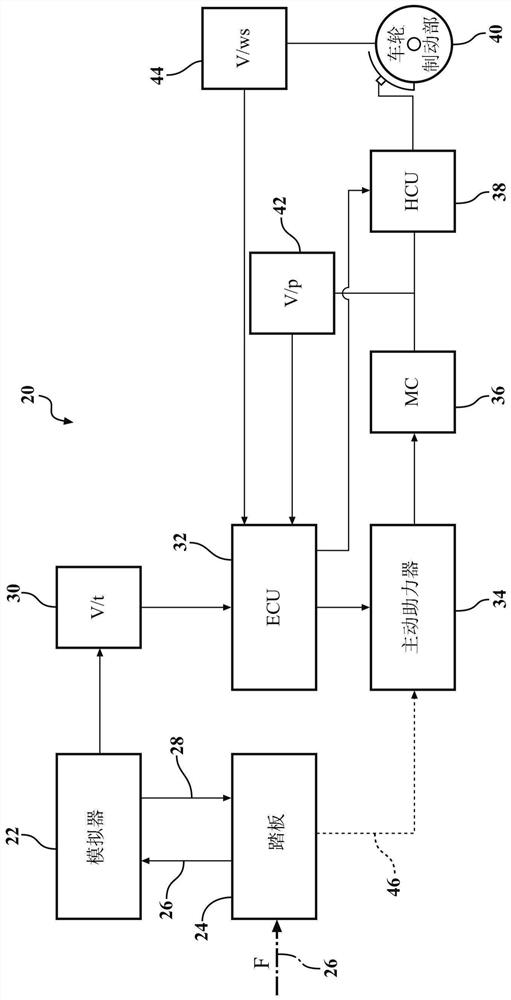

[0014] Referring to the drawings, wherein like reference numerals indicate corresponding parts throughout the several views, in figure 1 A braking system 20 (eg, a brake-by-wire system) including a pedal feel simulator or pedal feel simulator assembly 22 constructed in accordance with an embodiment of the present invention is generally shown in FIG.

[0015] Braking system 20 includes a brake pedal 24 that receives an input force indicated by arrow 26 from a driver of the vehicle. The input force 26 is transmitted through the brake pedal 24 to the pedal feel simulator assembly 22 which also transmits a simulated force / resistance 28 back to the brake pedal 24 . The braking system 20 may include a displacement sensor 30 for monitoring the travel of the brake pedal and transmitting a corresponding signal to the electronic control unit 32 . The electronic control unit 32 may be a central controller of the braking system 20 . Electronic control unit 32 sends control signals to ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com