Water feeding hose fixing structure of passenger train

A fixed structure, railway passenger car technology, applied in the direction of railway auxiliary equipment, etc., can solve the problems of heavy maintenance workload, casualties, low reliability, etc., achieve the effect of heavy maintenance workload, reduce bending frequency, and solve potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

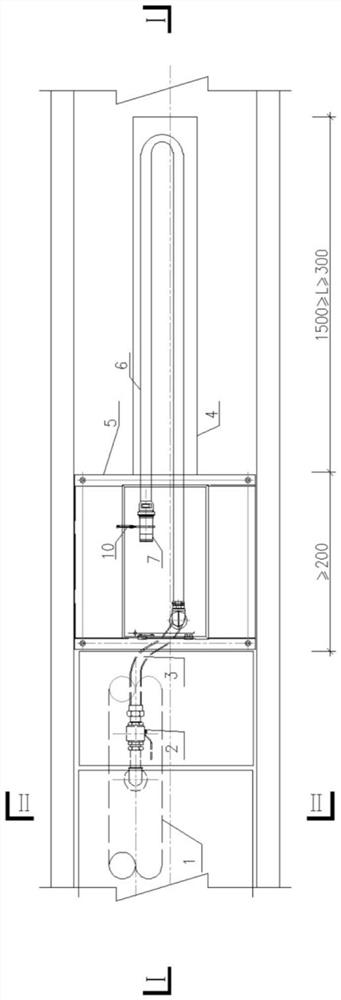

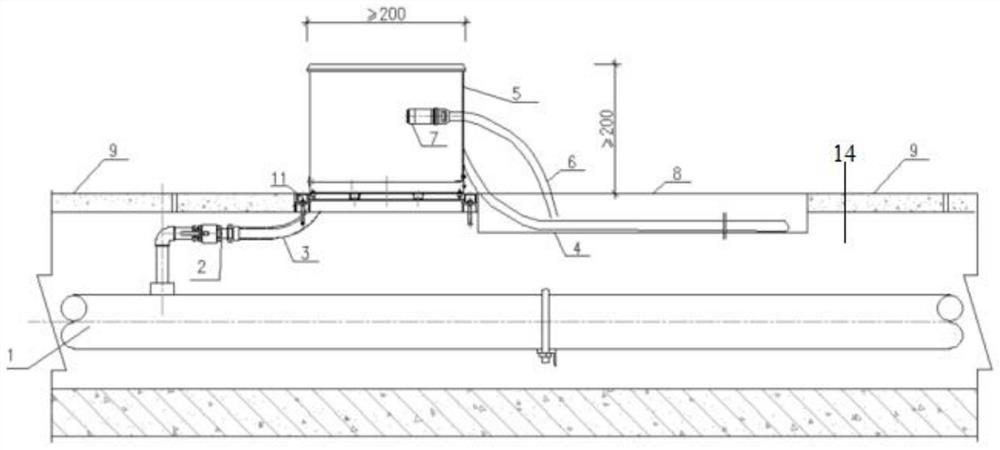

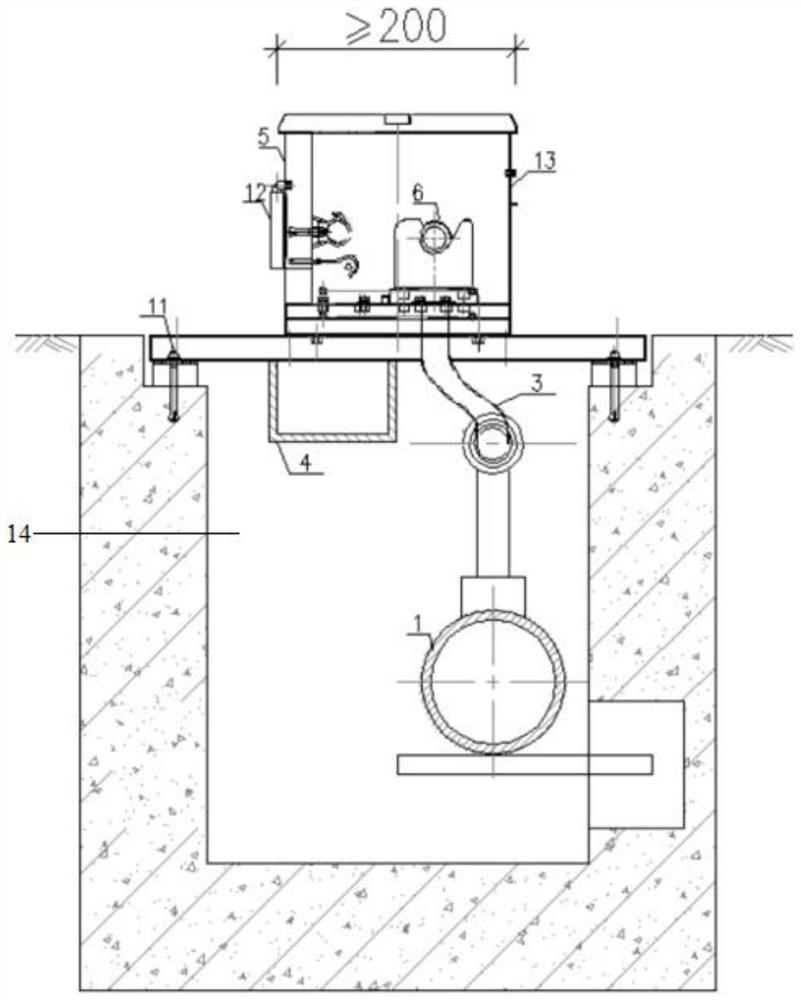

[0028] like Figure 1 - Figure 3 , The embodiment of the present invention provides a railway hose fixing structure, including the upper water hose storage bin 4, the upper water unit cabinet 5, and the upper water dry tube 1, the upper water hose 6 is placed in the upper water soft In the pipe storage nano 4, one end of the upper water hose 6 is provided with an upper water joint 7 that communicates with the train tank, the upper water joint 7 being fixed within the upper water unit cabinet 5, and the water The other end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com