Purification device for waste alkali liquor in alkali washing and degreasing process of strip steel

A purification device and waste lye technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, special treatment targets, etc., can solve the problem of increasing the cost of environmental protection treatment of enterprises, reducing the service life of lye, and affecting the cleaning efficiency of lye And other problems, to achieve better filtering effect, reduce cleaning frequency, economical and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

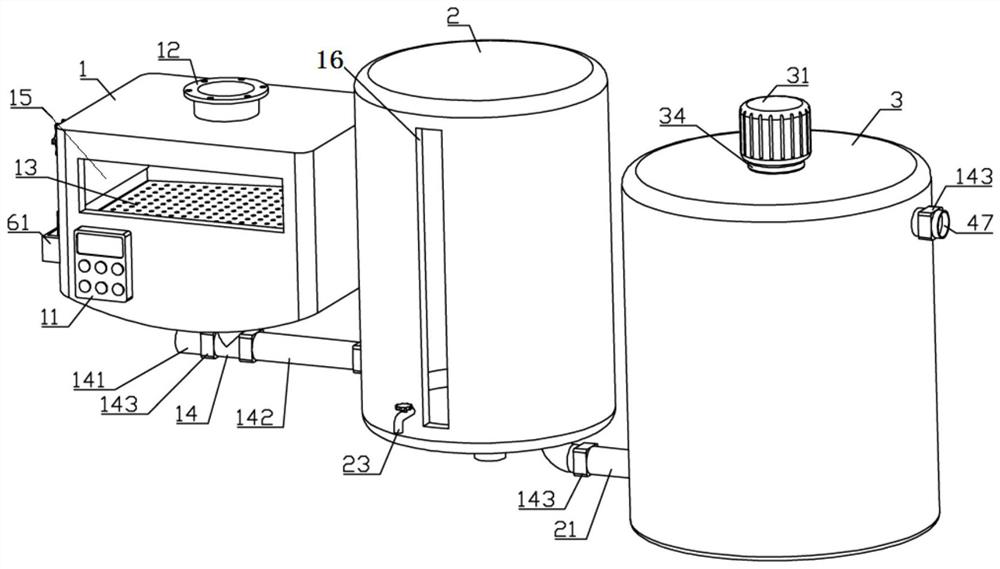

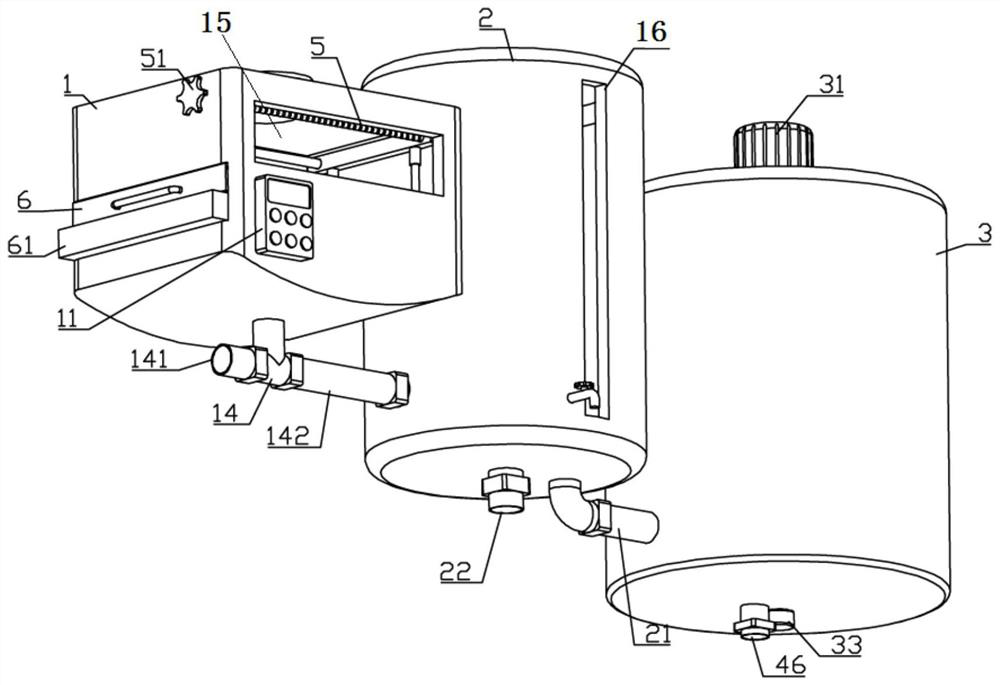

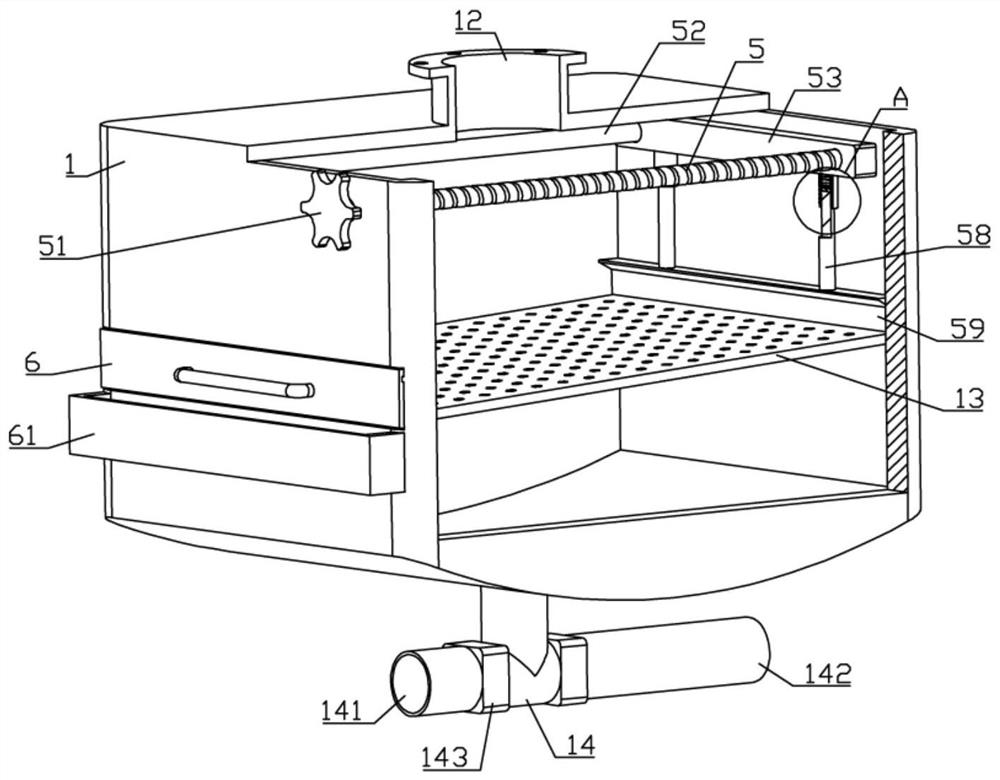

[0042] Such as Figure 1-7 As shown, the present invention is a purification device for spent caustic lye in the strip steel alkali washing and degreasing process, comprising a primary filter box 1, a temporary storage tank 2 and a second filter tank 3, and the liquid outlet at the bottom of the primary filter box 1 The mouth is connected with the liquid inlet pipe of the three-way pipe 14, and the three-way pipe 14 also includes a cleaning pipe 141, a first infusion pipe 142, and the end of the first infusion pipe 142 away from the primary filter box 1 is connected to the temporary storage tank 2. The liquid inlet is connected, and the liquid outlet located at the bottom of the temporary storage tank 2 is connected with the liquid inlet at the lower end of the second filter tank 3 through the second infusion tube 21;

[0043] The outer wall of the primary filter box 1 is provided with a control panel 11, the top of the primary filter box 1 is provided with a liquid inlet 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com