Tramcar turnout switch structure

A technology for trams and turnouts is applied in the field of pedestal tramway switch structures, which can solve the problems of inability to meet user requirements, assembly accuracy of the switch, wear resistance, and maintenance and repair questions, and achieve process production. The effect of short cycle, reduced maintenance and repair workload, and high assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

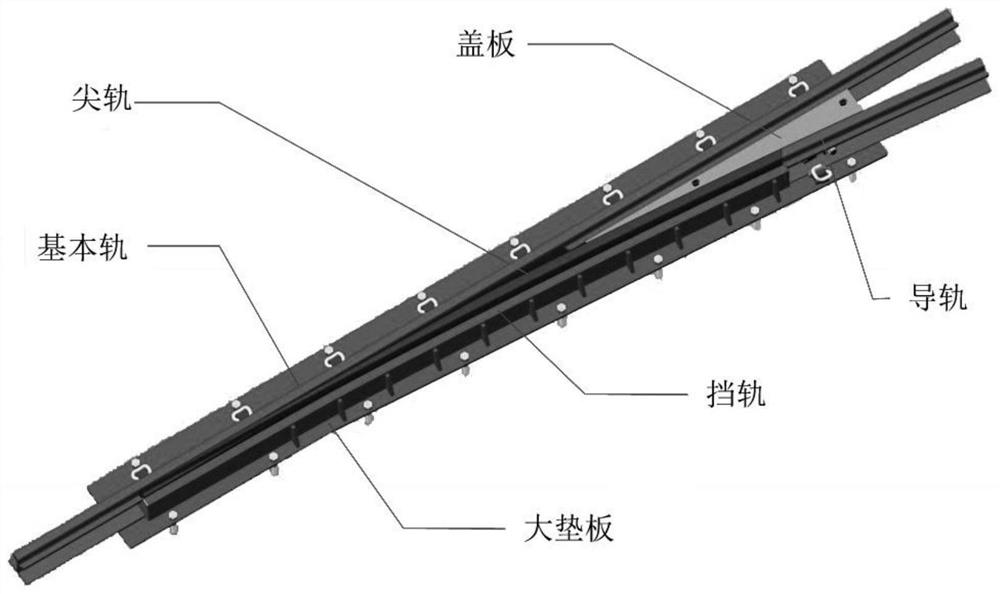

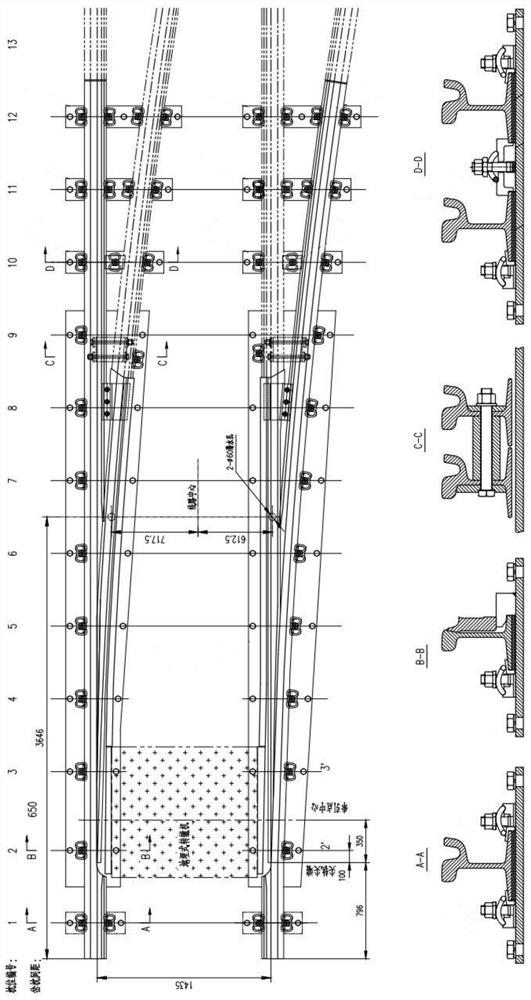

[0027] A tramway switch switch structure, such as Figure 6 As shown, it is mainly composed of a manganese steel base 1 and a straight basic rail 2 and a curved point rail 3 fixed inside the manganese steel base. The manganese steel base 1 includes a first connecting section 101 at the head, The second connecting segment 102 at the tail and the base segment 103 between the first connecting segment and the second connecting segment.

[0028] The base is integrally cast with high manganese steel, which has a short production cycle and a small amount of processing, which has great advantages in production cost. Since the base is integrally cast, after assembling the straight basic rail and the curved point rail, the overall stability of the structure is very good, and the assembly accuracy is also higher. Straight basic rails and curved point rails can be made of alloy steel plates, and their hardness is usually above 380HBW, which can well meet the user's requirements for wear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com