Rail pressure control method of high-pressure common-rail diesel engine

A high-pressure common rail and diesel engine technology, which is applied in engine control, electrical control, fuel injection control, etc., can solve the problem that the effect of rail pressure stability needs to be improved, and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

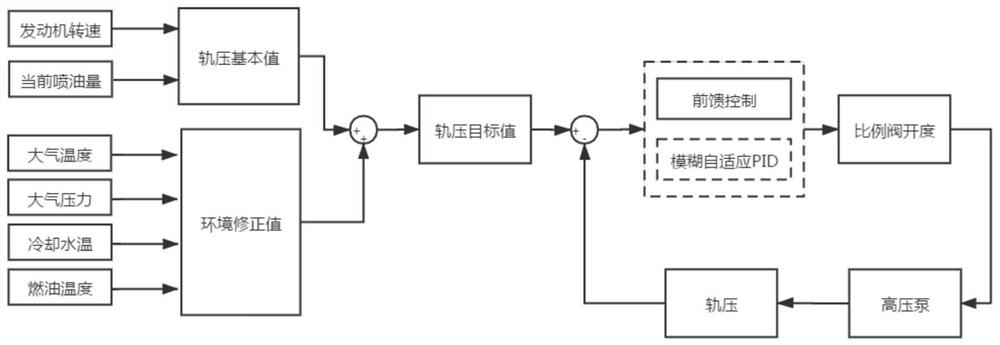

[0026] A rail pressure control method of a high-pressure common rail diesel engine provided by the present invention includes the following contents:

[0027] According to the different working conditions of the diesel engine, the rail pressure control strategy of the high-pressure common rail diesel engine is determined:

[0028] The engine starting condition adopts open-loop control;

[0029] The working condition after starting adopts closed-loop control.

[0030] Specifically, at the initial stage of engine starting, the engine speed is low and the pressure in the common rail is low. In order to make the engine start quickly, an open-loop control strategy is adopted. That is, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com