Carbon ceramic brake disc

A technology of brake discs and carbon ceramics, applied in the field of brake discs, can solve problems such as lack of installation devices, low strength of brake discs, and reduced use efficiency, so as to improve use efficiency and service life, improve heat dissipation effect, and increase service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

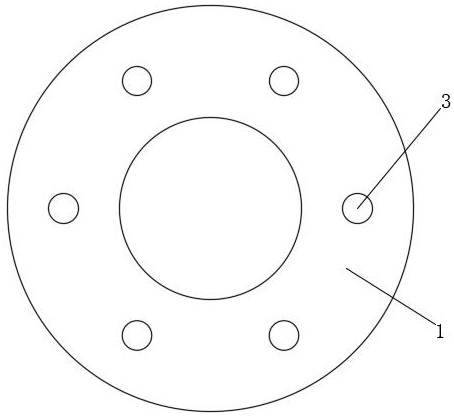

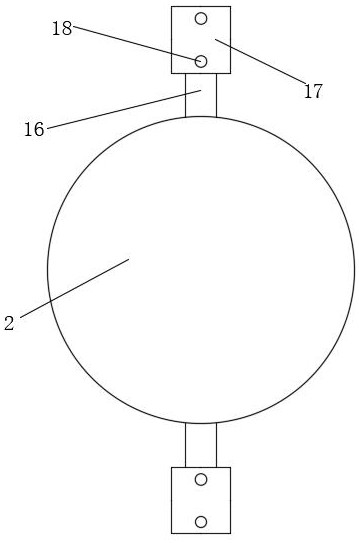

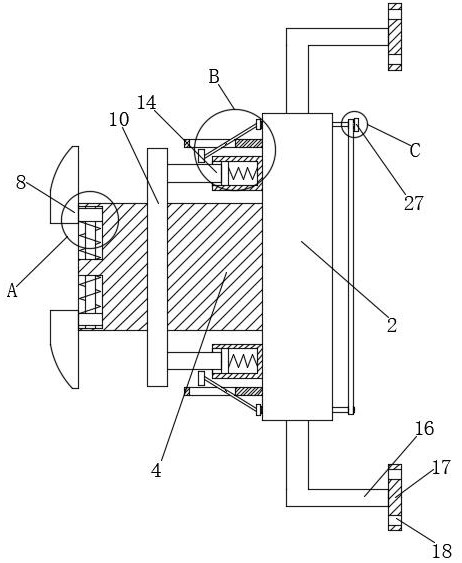

[0029] refer to Figure 1-6 , a carbon ceramic brake disc, including a disc body 1 and a side plate 2. There are several heat dissipation holes 3 on the disc body 1. The disc body 1 is made of carbon ceramics. The left side of the side plate 2 is fixedly installed with a mounting column 4. 4 is slidably installed with a shielding device, the mounting column 4 is slidably installed with a clamping device, two mounting rods 16 are symmetrically fixedly installed on the side plate 2, and mounting plates 17 are fixedly mounted on the two mounting rods 16. Two threaded holes 18 are opened symmetrically on the plate 17, two fixed plates 19 are symmetrically fixedly installed on the side plate 2, fixing devices are slidingly installed on the two fixed plates 19, and two symmetrical threads are installed on the side plate 2. Screw rod 26, two screw rods 26 are correspondingly connected with two fixing devices, two screw rods 26 are fixedly equipped with drive wheels 28, two drive whee...

Embodiment 2

[0040] refer to Figure 1-6 , a carbon ceramic brake disc, including a disc body 1 and a side plate 2, a plurality of cooling holes 3 are opened on the disc body 1, the disc body 1 is made of carbon ceramics, and a mounting column 4 is installed on the left side of the side plate 2 by welding. A shielding device is slidably installed on the column 4, a clamping device is slidably installed on the mounting column 4, two mounting rods 16 are installed symmetrically on the side plate 2 by welding, and a mounting plate 17 is installed on the two mounting rods 16 by welding. Two threaded holes 18 are opened symmetrically on the two mounting plates 17, and two fixing plates 19 are installed symmetrically by welding on the side plate 2, and fixing devices are slidingly installed on the two fixing plates 19, and the symmetrical threads on the side plate 2 Two screw rods 26 are installed, and the two screw rods 26 are connected to the corresponding rotation of the two fixing devices. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com