Screen material toughness detection device

A technology for detection devices and screens, which is applied to measuring devices, analyzing materials, and applying stable tension/pressure to test the strength of materials, etc., which can solve problems such as safety accidents and increased use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

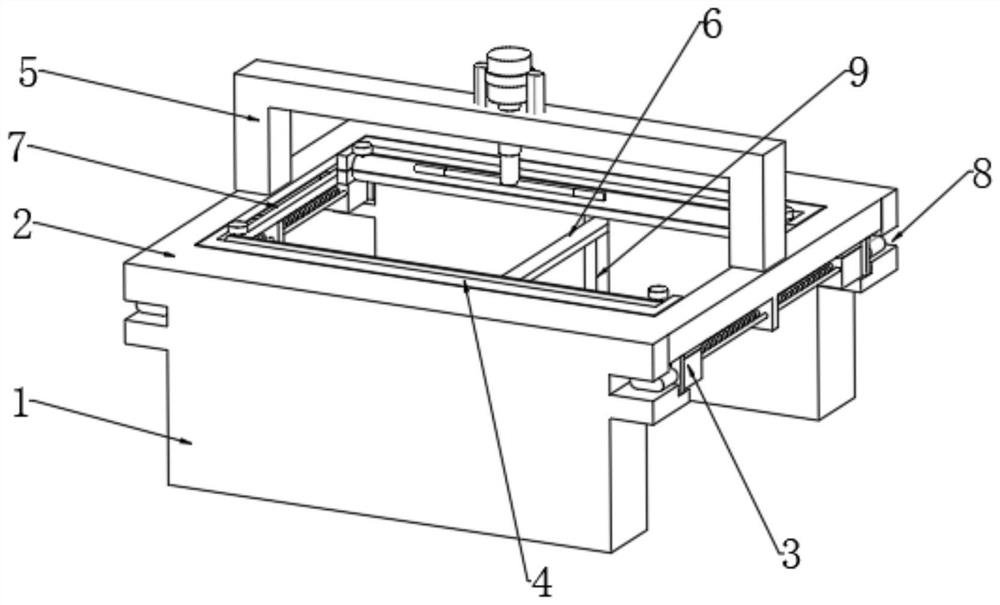

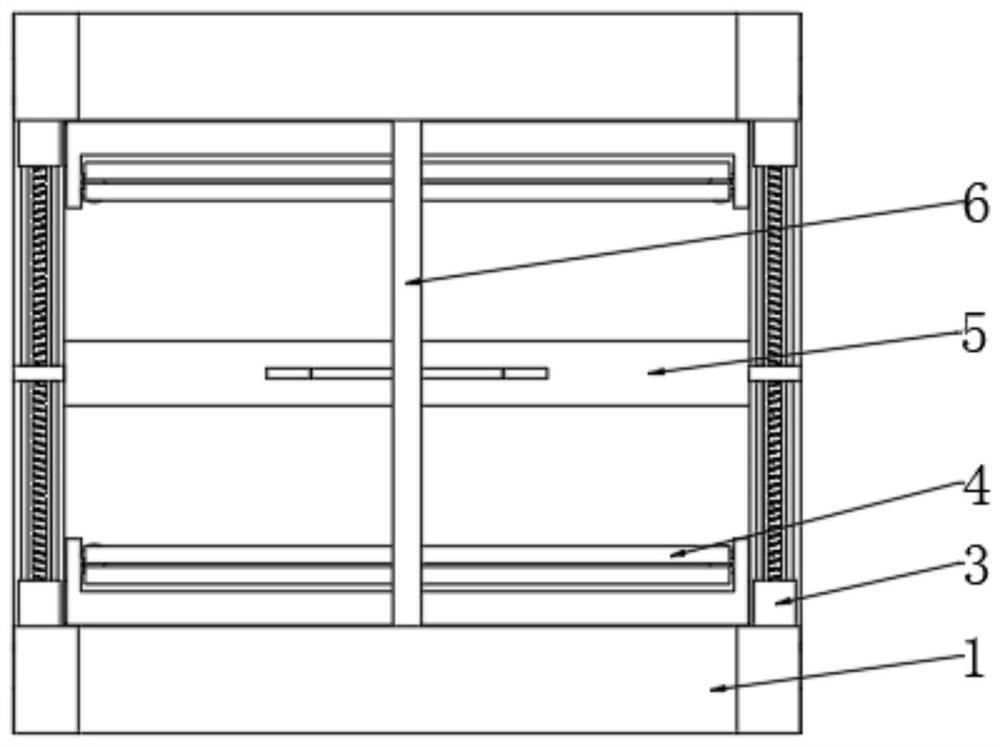

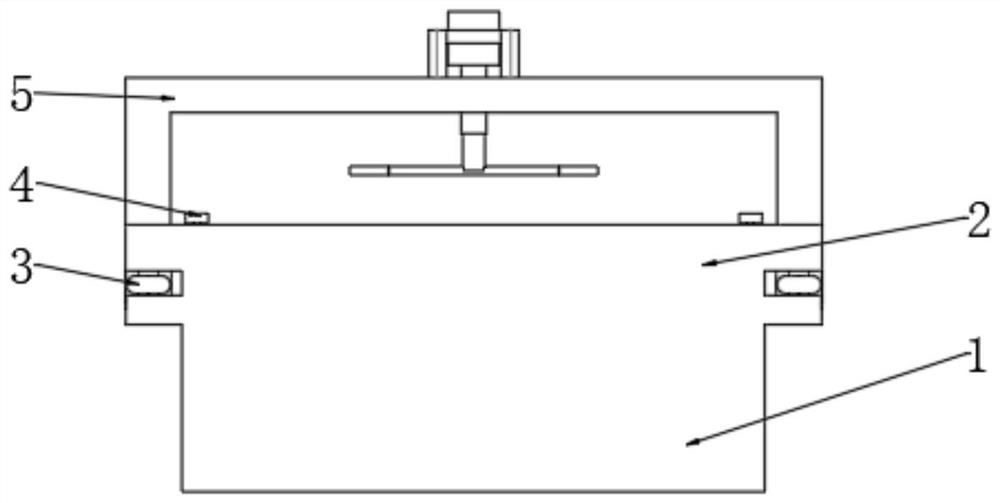

[0028] Please refer to Figure 1 to Figure 8 ,in, figure 1 It is a schematic diagram of a three-dimensional structure of a preferred embodiment provided by the present invention, figure 2 for figure 1 The schematic diagram of the planar structure shown in the top view, image 3 for figure 1 The front view plane structure diagram shown, Figure 4 for figure 1 The schematic diagram of the side structure is shown, Figure 5 for figure 1 The structural diagram of the extrusion mechanism shown, Figure 6 for figure 1 The schematic diagram of the structure of the fixing mechanism is shown, Figure 7 for figure 1 The structure diagram of the guiding mechanism shown, Figure 8 for figure 1 The structure diagram of the observation mechanism is shown. It includes: a support leg 1, the top of the support leg 1 is fixedly supported by the support pla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap