Portable ultrahigh vacuum low-temperature observation cavity with microcell characterization function and operation method

An ultra-high vacuum and characterization technology, applied in measurement devices, material analysis by optical means, instruments, etc., to achieve the effect of reducing difficulty, strong applicability, and ensuring low temperature conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

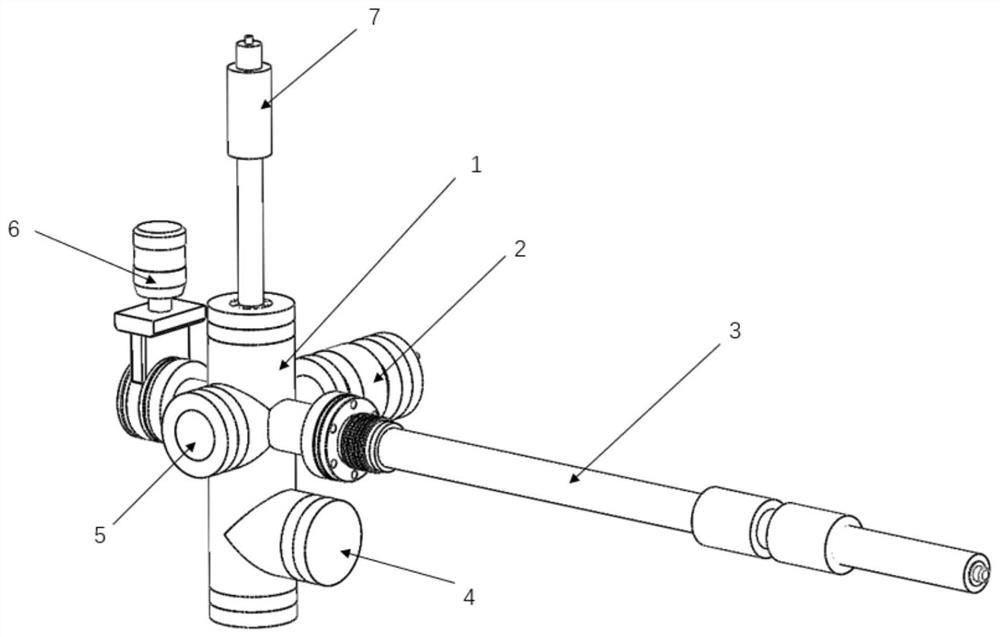

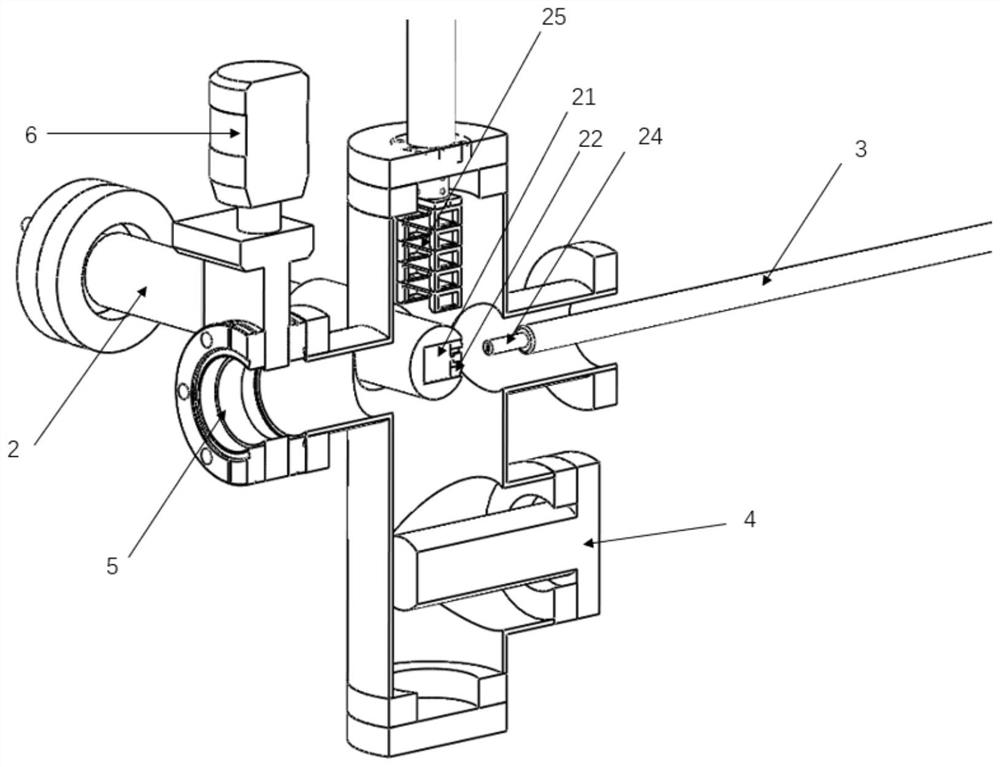

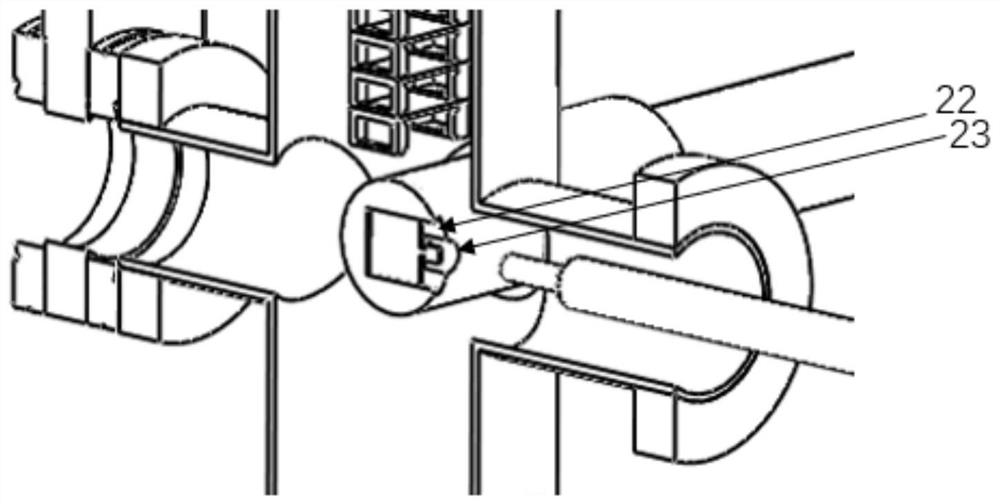

[0037] refer to figure 1 , 2 As shown, the present invention has a portable ultra-high vacuum low-temperature observation chamber with micro-area characterization function. Hand valve 6, sample storage rod 7, sample storage rack 25 and cold cavity.

[0038] refer to figure 1 , the ultra-high vacuum main chamber 1 has a multi-port tubular structure and is made of high-strength materials (such as stainless steel), so that the ultimate vacuum in the chamber can meet the ultra-high vacuum requirements; the ultra-high vacuum main chamber 1 is welded with 6 Sealing flange, the front wall is connected with the sample transfer rod 3, the flange below the same side of the sample transfer rod 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com