Adjustment drive having a brush card assembly with integrated printed circuit board

A technology for regulating drives, printed circuit boards, applied to electromechanical devices, electric components, and connections to control/drive circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

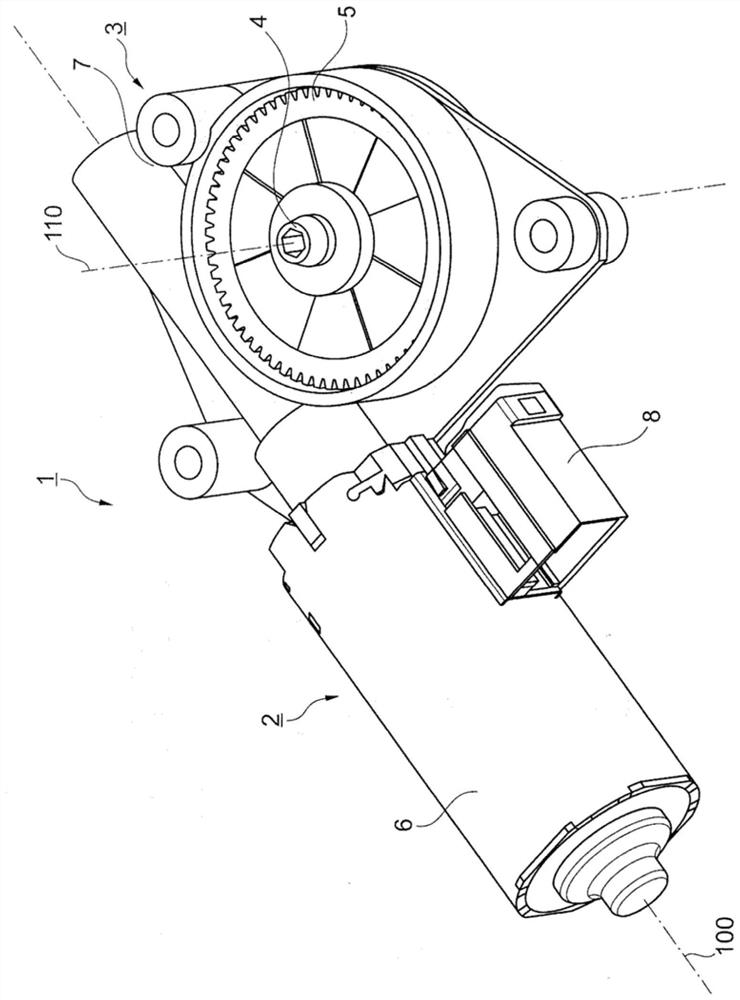

[0024] figure 1 The adjusting drive 1 comprising a brushed DC motor 2 and a gear 3 is shown in . In commutator motors, the current from the power supply or control unit is supplied via brushes, which are applied to the commutator, which is divided into laminations and serves to divert the current. The laminations are insulated from each other on the circumference of the commutator and, as the rotor formed by the armature winding, motor shaft and commutator turns, current is supplied in turn via the brushes accordingly. A direct voltage, such as a PWM signal, is applied to the brushes by a control device not shown, so that the current is established. The DC motor 2 is designed to drive an output shaft 4 . The transmission device 3 arranged between the DC motor 2 and the output shaft 4 is preferably a worm gear transmission device. The motor shaft is preferably designed as a worm. The corresponding worm gear 5 is mounted on the output shaft 4 . For the geometric description...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com