Construction method of overhead line jacking underpass type reinforced concrete frame bridge by auxiliary beam lifting method

A reinforced concrete and overhead line technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem of difficulty in adjusting the position of horizontal lift beams or D-type beams, heavy weight of D-type beams, troublesome bolts, etc. problems, to achieve the effect of convenient jacking operation, reduced friction, and firm positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-7The application is described in further detail.

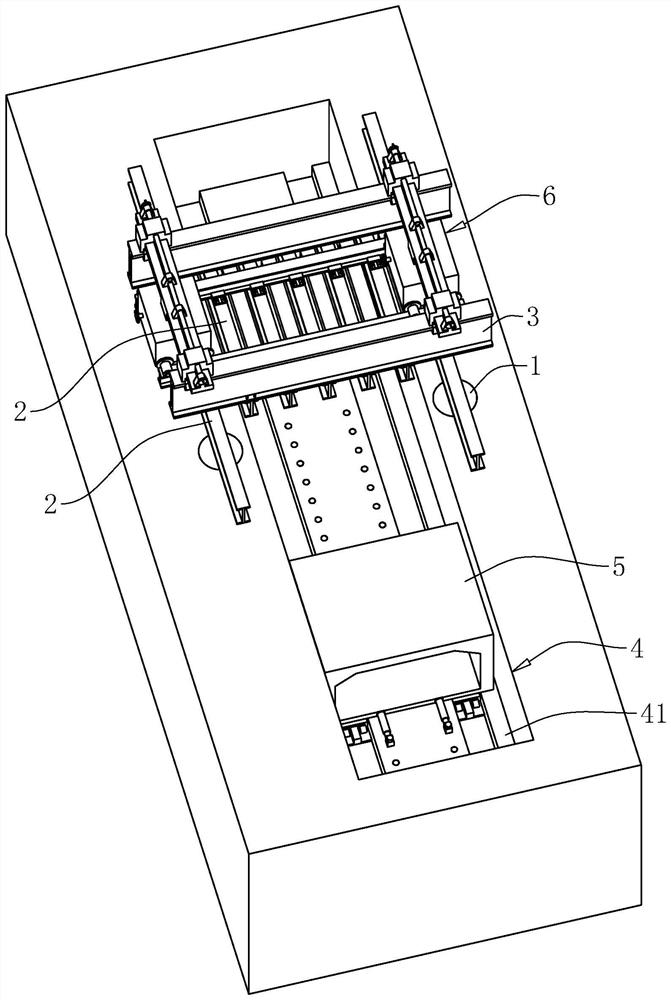

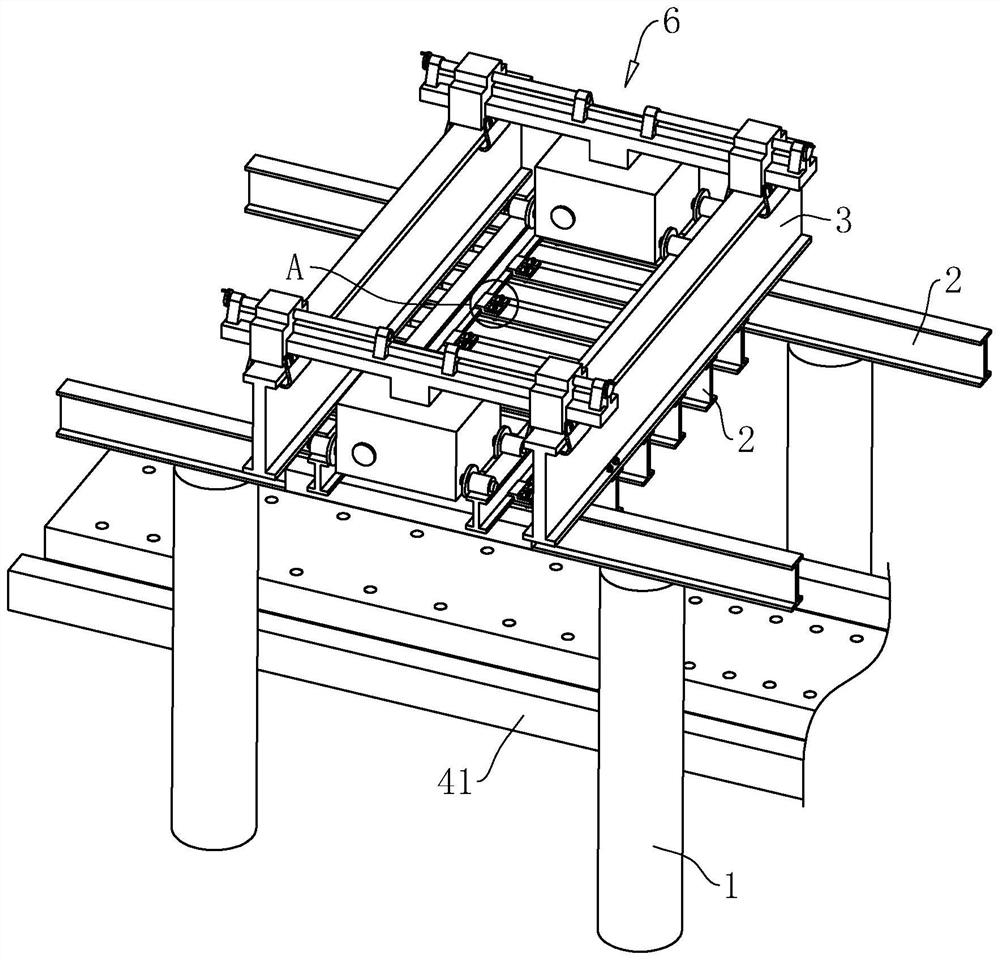

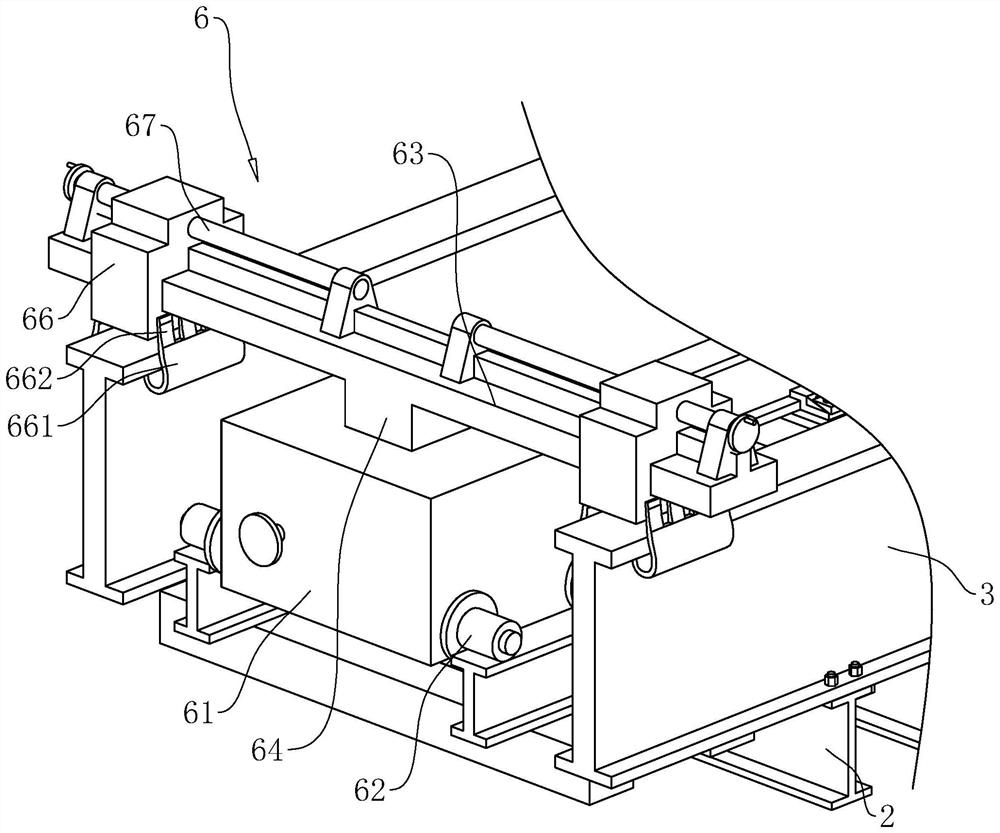

[0040] The embodiment of the present application discloses a construction method of a reinforced concrete frame bridge with a convenient beam lifting method for jacking and passing through an overhead line. refer to figure 1 , including making vertical buttresses 1, laying horizontal lifting beams 2, connecting beams 3, excavating ducts 4, making frame 5 and jacking frame 5.

[0041] refer to figure 1 , to make the vertical pier 1, choose a suitable position and be located on both sides of the existing line, the existing line is the rail, there are at least two sets of vertical pier 1, and one set of vertical pier 1 is in the same section of the existing line Two vertical buttresses 1 at the position, first excavate pile pits on both sides of the existing line. The pile pits are cylindrical and can be drilled with a drilling machine. Concrete is poured inside to form a vertical pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com