Single-layer well wall with grouting water stop connecting piece and construction method thereof

A technology of connectors and well walls, which is applied in wellbore lining, shaft equipment, earthwork drilling and mining, etc., can solve the problems of rising wellbore cost, difficulty in guaranteeing the water sealing performance of wellbore walls, and multiplied difficulty in the prevention and control of wellbore cracking, so as to save Low cost, good overall water sealing performance, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

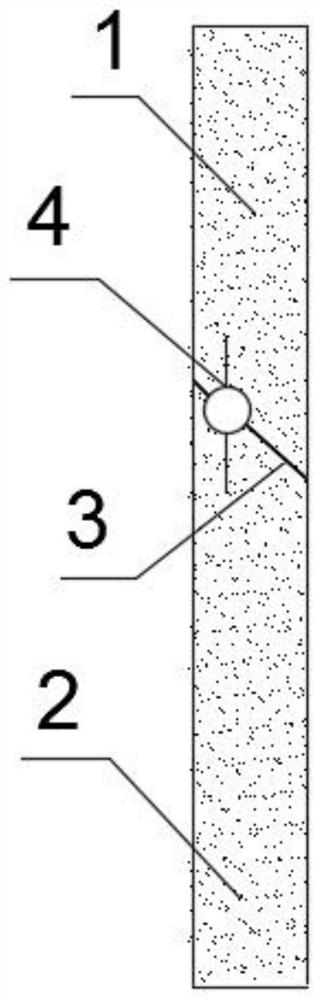

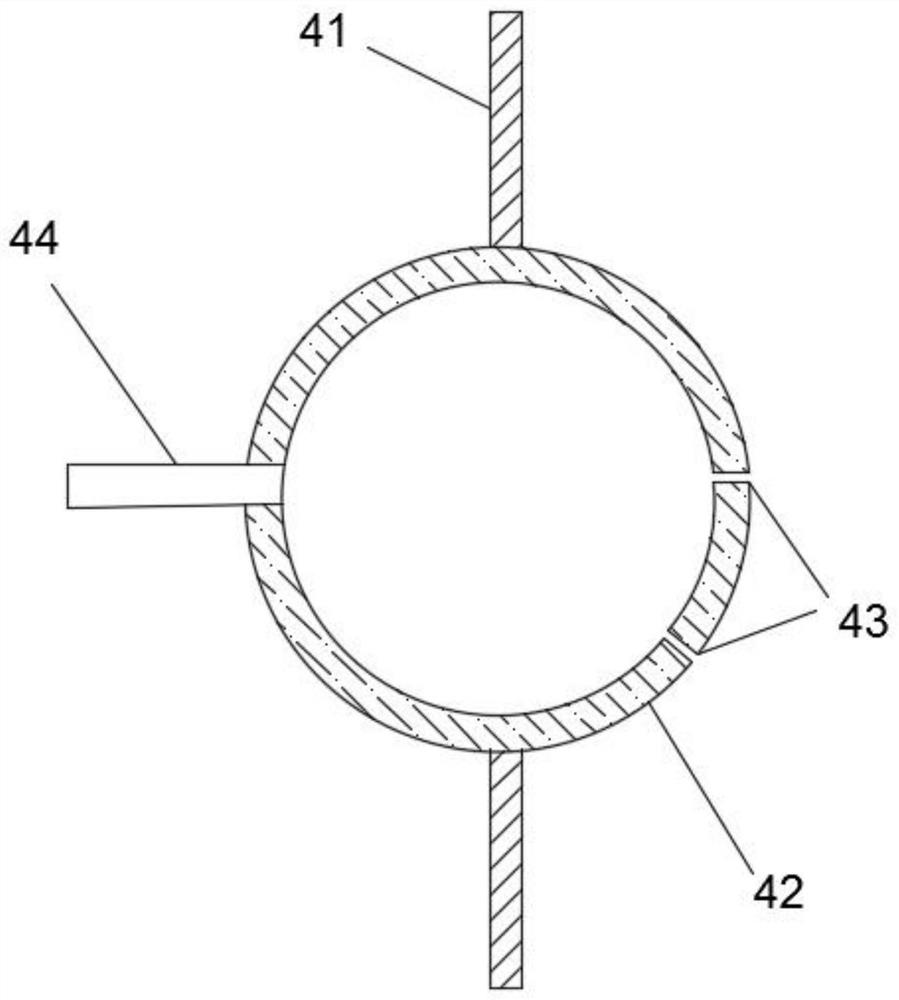

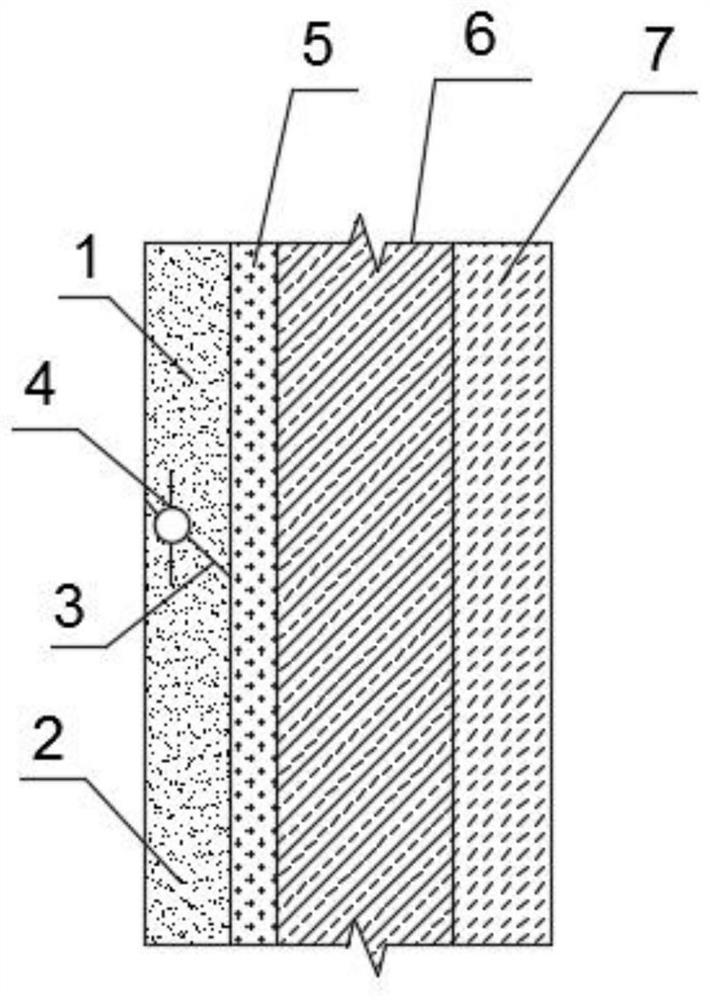

[0033] A single-layer well wall with grouting and water-stop connectors, comprising an upper well wall 1 and a lower well wall 2, a construction joint 3 is arranged between the upper well wall 1 and the lower well wall 2, and the At the construction joint 3, the upper well wall 1 and the lower well wall 2 are connected by a grouting water-stop connecting piece 4, and the grouting water-stop connecting piece 4 includes a flexible pipe 42, and the flexible pipe 42 is in a closed ring shape And embedded between the upper shaft wall 1 and the lower shaft wall 2, the upper and lower ends of the flexible pipe 42 are fixedly connected with steel plate sides 41, and the steel plate sides 41 are buried in the upper shaft wall 1 and the lower shaft wall 2 respectively. , the flexible pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com