Crushing and separating type sewage pump

A sewage pump and separation type technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of large loss of energy consumption, affecting sewage, affecting discharge, etc., to reduce flow channel blockage, improve crushing capacity, and reduce entanglement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

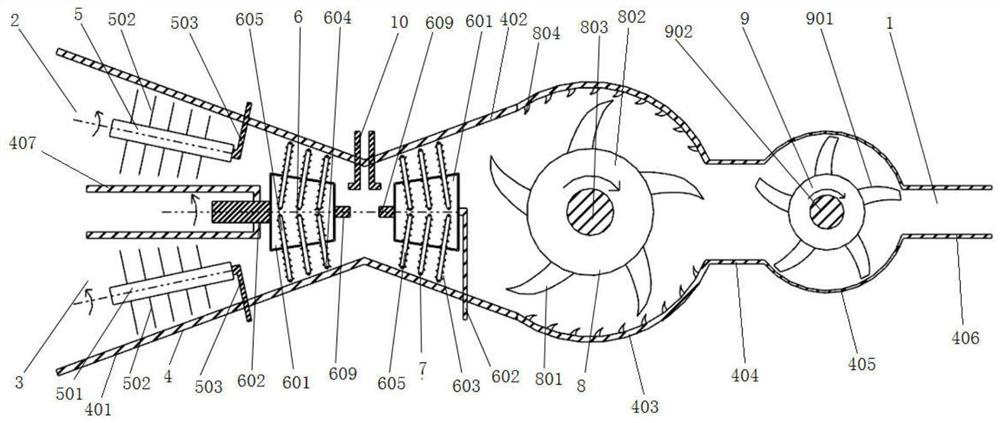

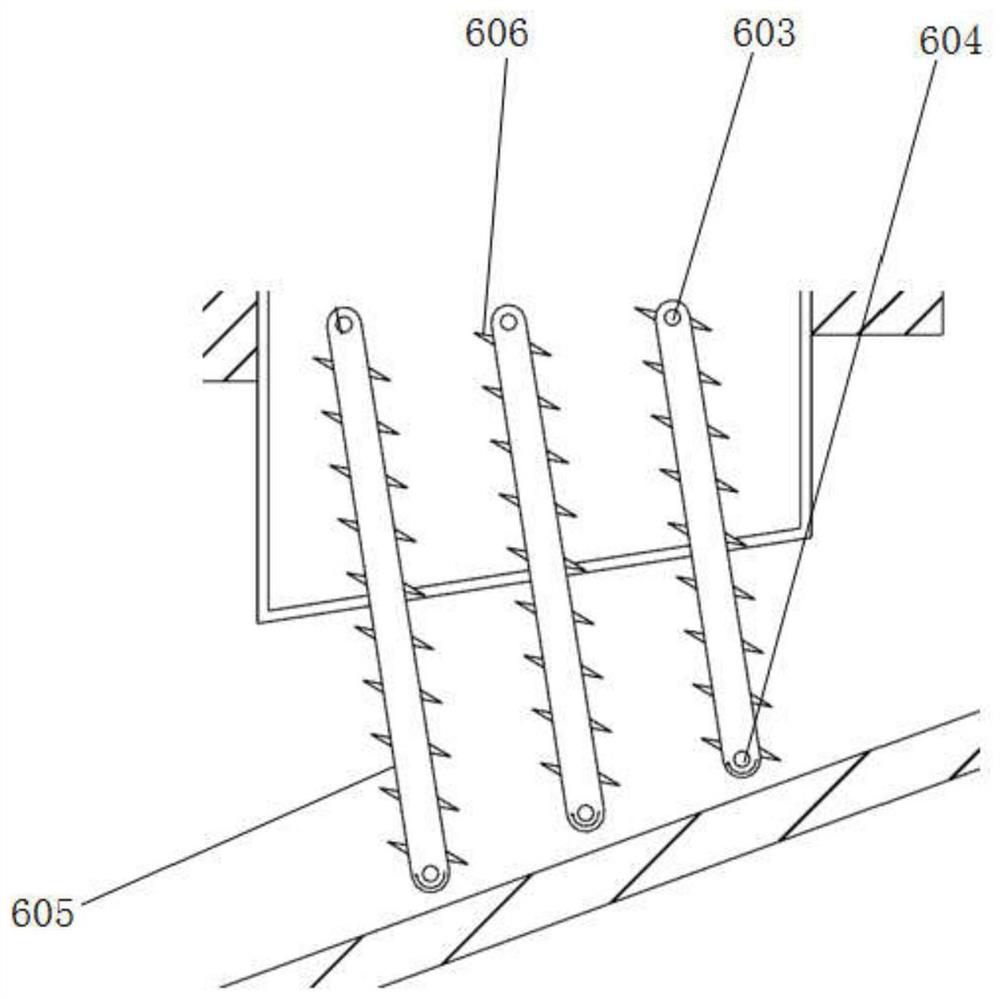

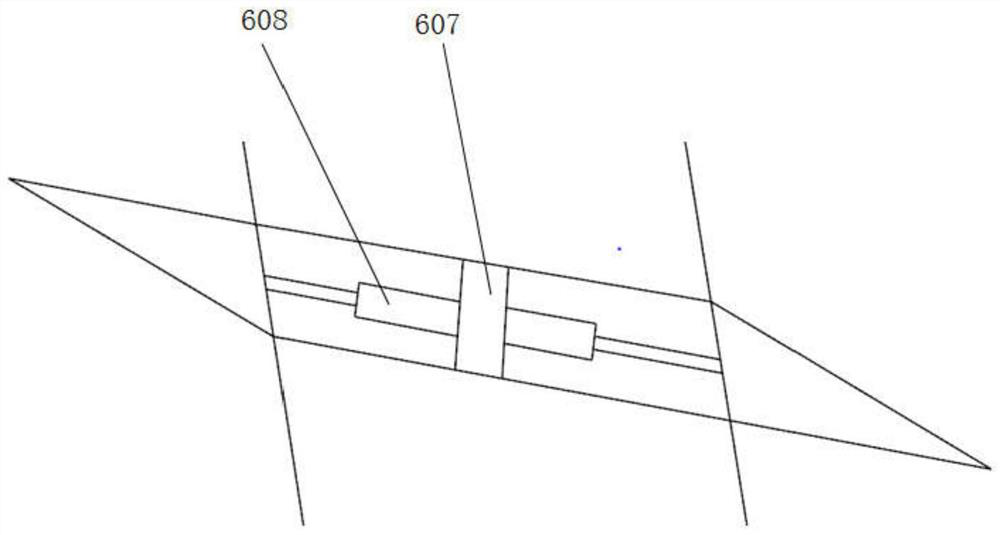

[0025] Such as figure 1 As shown, a broken and separated sewage pump of the present invention includes a sewage pump casing 4, a cylindrical breaker 5, a left trapezoidal broken recoverer 6, a right trapezoidal broken recoverer 7, an impeller breaker 8 and an impeller 9.

[0026] The sewage pump housing 4 of the present invention includes a tapered tapered housing 401, a gradually expanding conical housing 402, a large arc-shaped housing 403, an equal-diameter transition housing 404, a small arc-shaped housing 405, an equal-diameter outlet housing 406 and a partition housing 407, wherein The partition housing 407 divides the inlet of the tapered conical housing 401 into an upper inlet flow channel 2 and a lower inlet flow channel 3, wherein the upper inlet flow channel 2 and the lower inlet flow channel 3 are separated by the sewage pump housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com