MOX assembly circle run-out measuring device

A measuring device, the technology of circular beating, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of low measurement accuracy, damage to human health, low accuracy, etc., to achieve high measurement accuracy, simple structure, promotion The effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

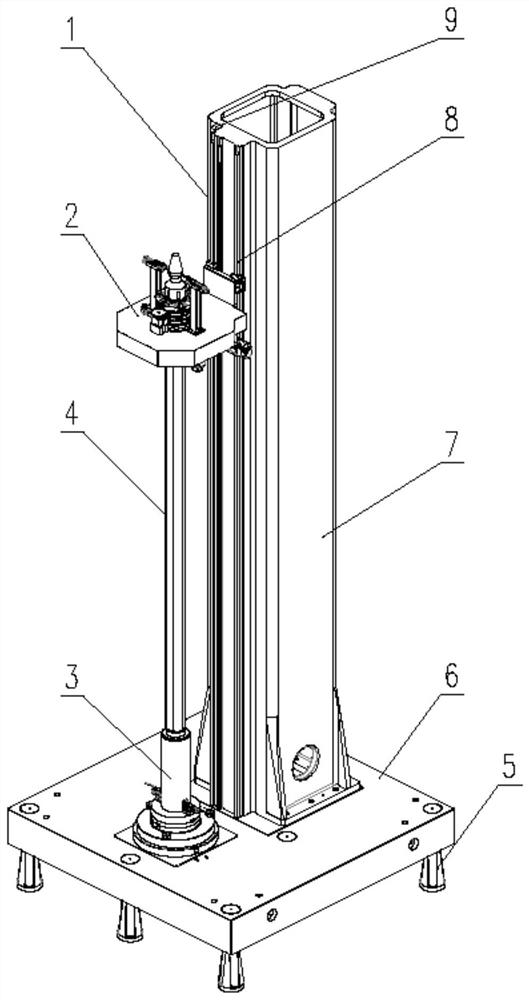

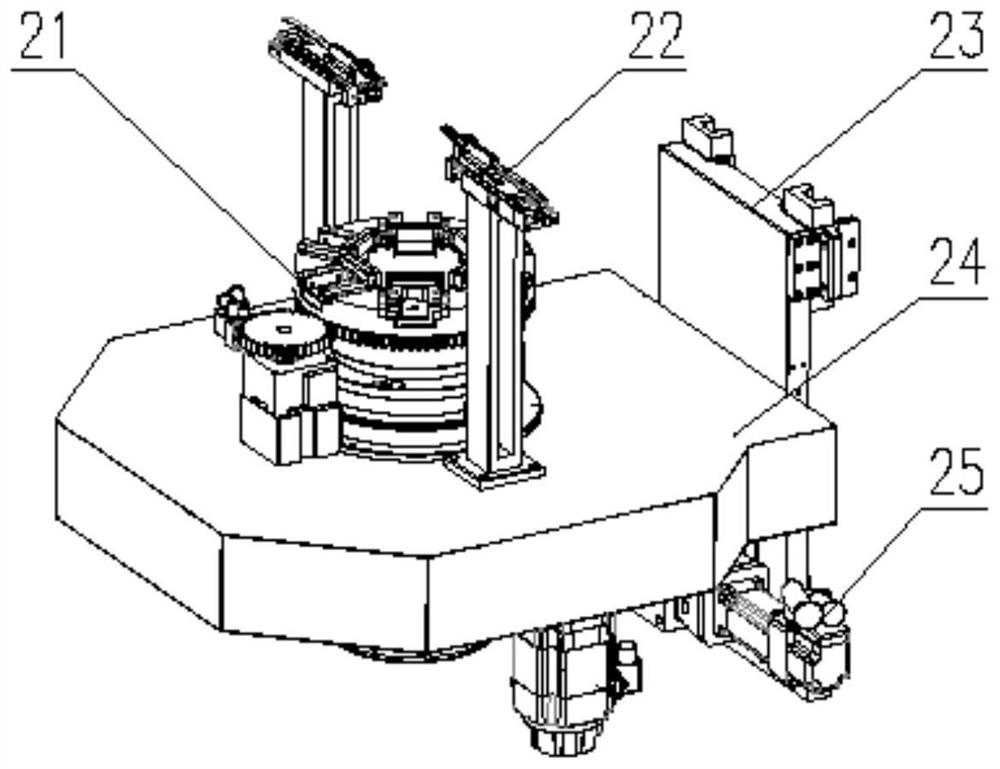

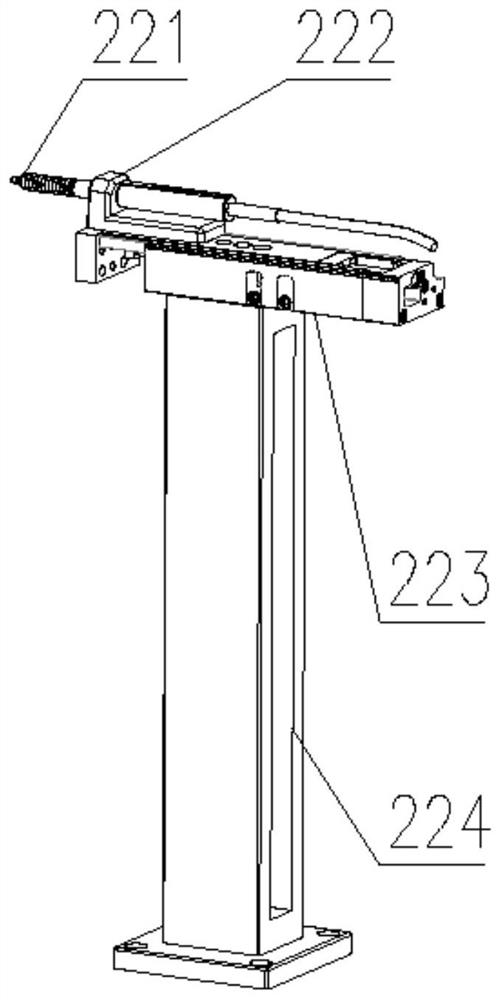

[0031] This embodiment discloses a MOX component circular runout measurement device, such as figure 1 As shown, it includes a support stand 1, a rotating mechanism 2, and a measurement mechanism. The support stand 1 is used to support the MOX assembly 4. The measurement mechanism includes a first measurement assembly 22, and the first measurement assembly 22 includes a first length gauge 221, a first Measuring cylinder 223, the first measuring cylinder 223 is used to drive the first length gauge 221 to approach the outer circumference of the head end of the MOX assembly when the rotating mechanism 2 drives the MOX assembly 4, and the first length gauge 221 is used to connect with the MOX assembly 4 heads Measure the circular runout size of the cylindrical surface at the head end of the MOX component 4 when the ends are in contact. In this embodiment, the measurement of the circular runout of the MOX assembly 4 is accomplished by the rotating mechanism 2 and the first measuring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com