Flexible sensor capable of simultaneously detecting pressure-strain bimodal signals and preparation method thereof

A flexible sensor, dual-mode technology, applied in the field of flexible sensors, can solve the problem of inability to distinguish and identify excitation signals, and achieve the effects of improving sensitivity, simple process flow, and guaranteeing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

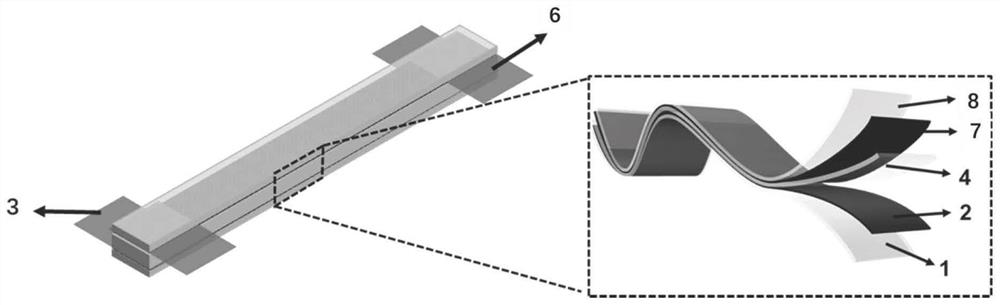

[0030] The present invention will be further explained below in conjunction with the accompanying drawings.

[0031] Such as figure 1 As shown, a flexible sensor for simultaneous detection of pressure-strain dual-mode signals includes a lower packaging protection layer 1, a lower electrode plate 2, a first metal lead layer 3, a porous dielectric layer 4, and a second Metal lead layer 6 , upper electrode plate 7 , and upper package protection layer 8 . Wherein, the materials of the lower electrode plate 2 and the upper electrode plate 7 are low-dimensional nanomaterials. When the device is prepared, the low-dimensional nanomaterials of the lower electrode plate 2 diffuse downwardly to the upper surface of the encapsulation protective layer 1 to form a first diffusion layer, and the upper electrode The low-dimensional nanomaterials of the plate 7 diffuse to the upper surface of the porous dielectric layer 4 to form a second diffusion layer, and the low-dimensional nanomaterials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com