Three-dimensional tooth profile design method for harmonic reducer flexible gear

A harmonic reducer and design method technology, applied in complex mathematical operations, geometric CAD, special data processing applications, etc., can solve the problems of meshing and meshing interference, affecting the operating reliability and service life of harmonic reducers, etc. Achieve the effect of reducing tooth surface wear and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The following is further described in detail through specific implementation methods:

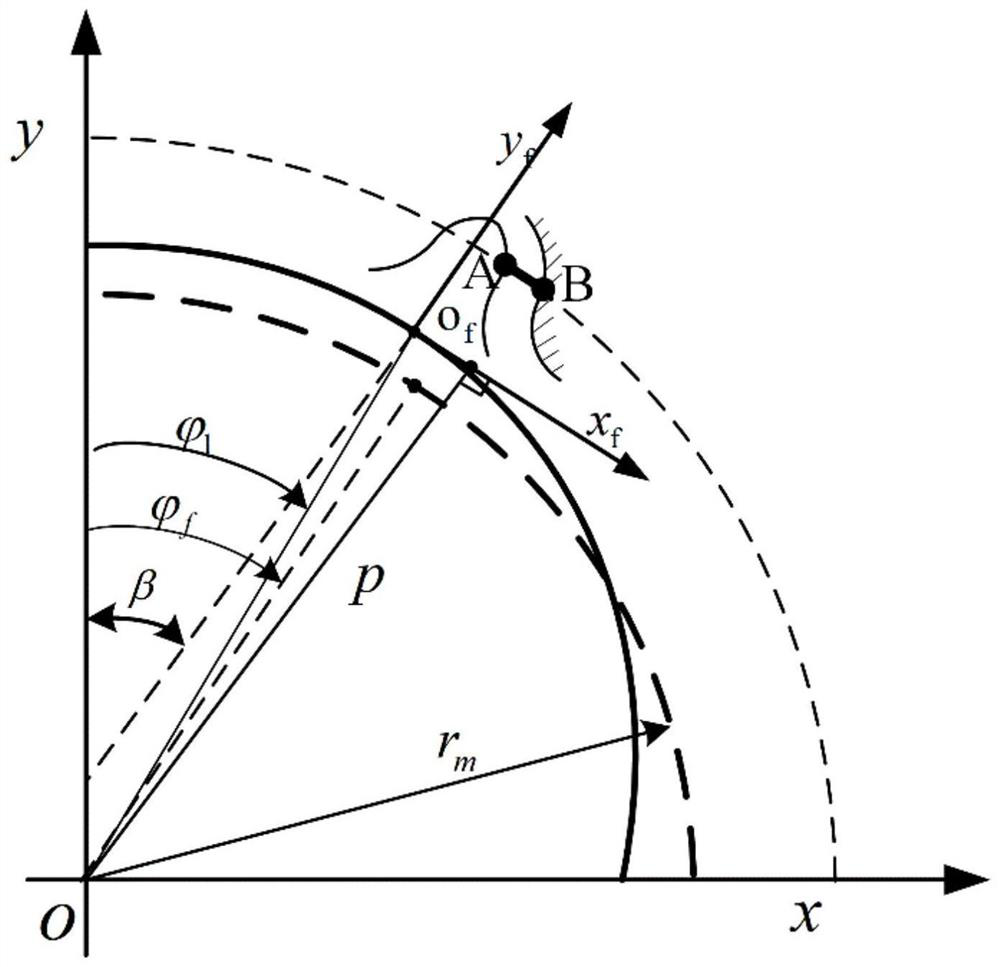

[0061] The technical problem to be solved by the present invention is to provide a method for designing a three-dimensional tooth profile of a harmonic reducer flexspline; this method is based on the premise that the two-dimensional tooth shape parameters of the harmonic reducer Mesh interference phenomenon, considering the circumferential stretch of the flexspline ring gear under load conditions, calculate the displacement h of different sections of the flexspline ring gear, and obtain the three-dimensional displacement curve of the flexspline ring gear.

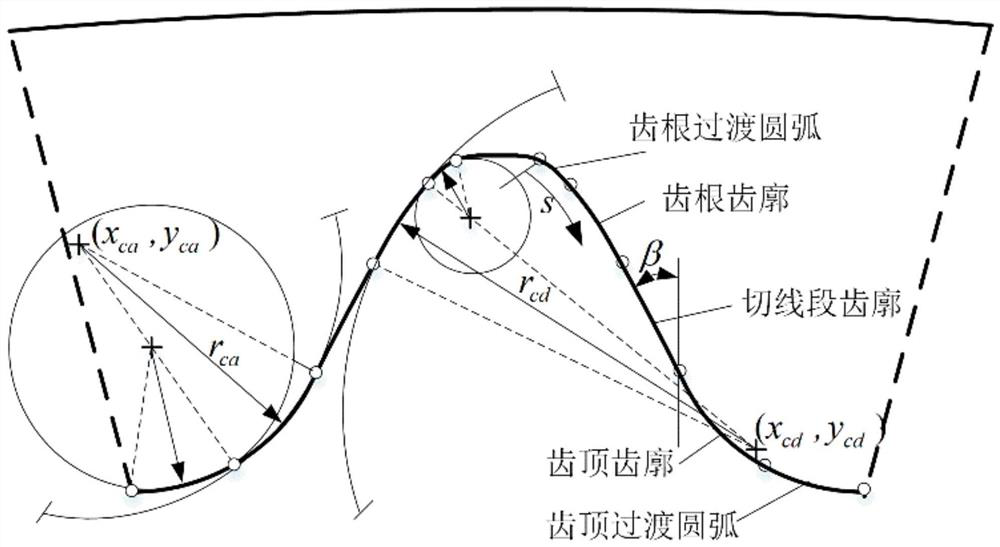

[0062] Taking the double-arc harmonic gear as an example, the technical solution of the present invention is described in detail as follows in conjunction with the accompanying drawings:

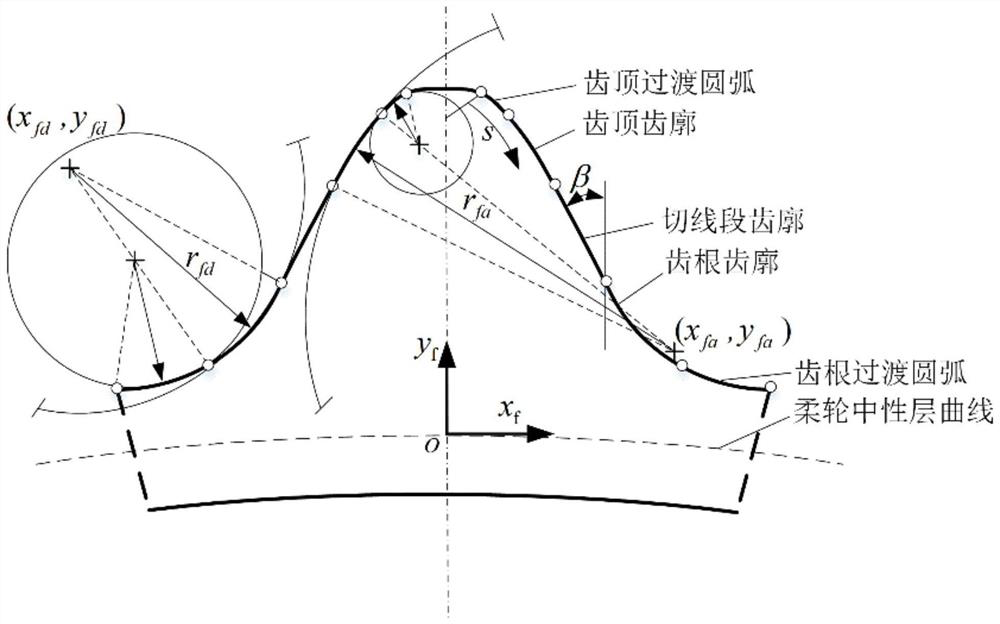

[0063] step 1, figure 1 It is a schematic diagram of the two-dimensional tooth profile of the harmonic gear flexspline, and the coordinate sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com