Processing method for gear of electric wheelchair

An electric wheelchair and processing method technology, applied in the field of gear processing, can solve the problems of high vibration and noise, high processing cost, long production cycle, etc., and achieve the effects of improving service life, reducing processing procedures, and reducing tooth surface wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

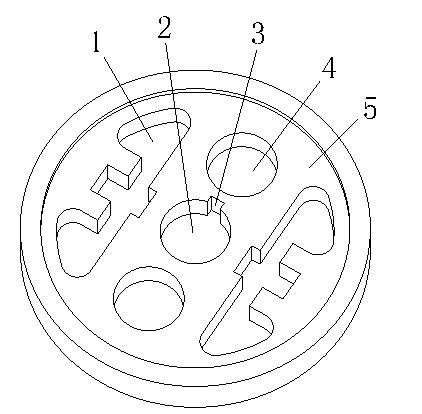

[0014] Embodiment: a kind of processing method of electric wheelchair car gear, as figure 1 shown. The wheel blank of the gear is directly pressed and formed by iron-based powder metallurgy materials; the pressed wheel blank is processed by finishing the datum hole 2 and two positioning end faces 5, and the keyway 3 is drawn on the inner wall of the datum hole 2; and then For gear hobbing and shaving. Direct compression molding is to use iron-based powder metallurgy materials to simultaneously press out the center hole, cavity 1 and lightening hole 4 on the wheel blank. A machining allowance of 0.5-1 mm is left in the center hole, and the center hole is processed into a reference hole 2 by finishing turning. A machining allowance of 0.5-1mm is left on the two ends of the center hole, and the two ends of the center hole are machined into two positioning end faces 5 with a lathe. The gear shaving is to modify the tooth shape and direction of the gear by grinding the gear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com