Method for controlling sliding nozzle device, and method for manufacturing slab

A technology of sliding nozzle and control method, which is applied in the direction of manufacturing tools, casting equipment, casting molten material containers, etc., and can solve the problems of inclusion generation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Next, Example 1 performed by the inventors of the present application will be described. In the examples, casting was carried out using the method for manufacturing slabs according to the above-mentioned embodiment, and the success rate of opening holes in the recasting process, that is, the success rate of re-drilling was investigated.

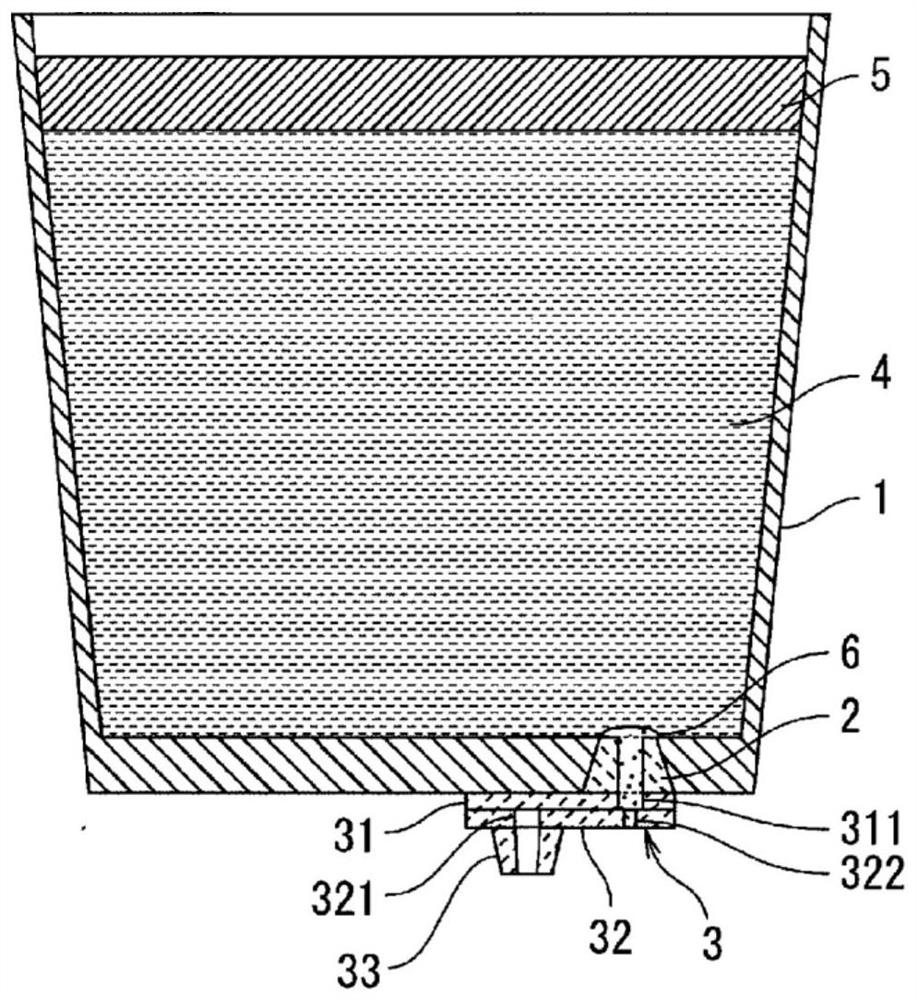

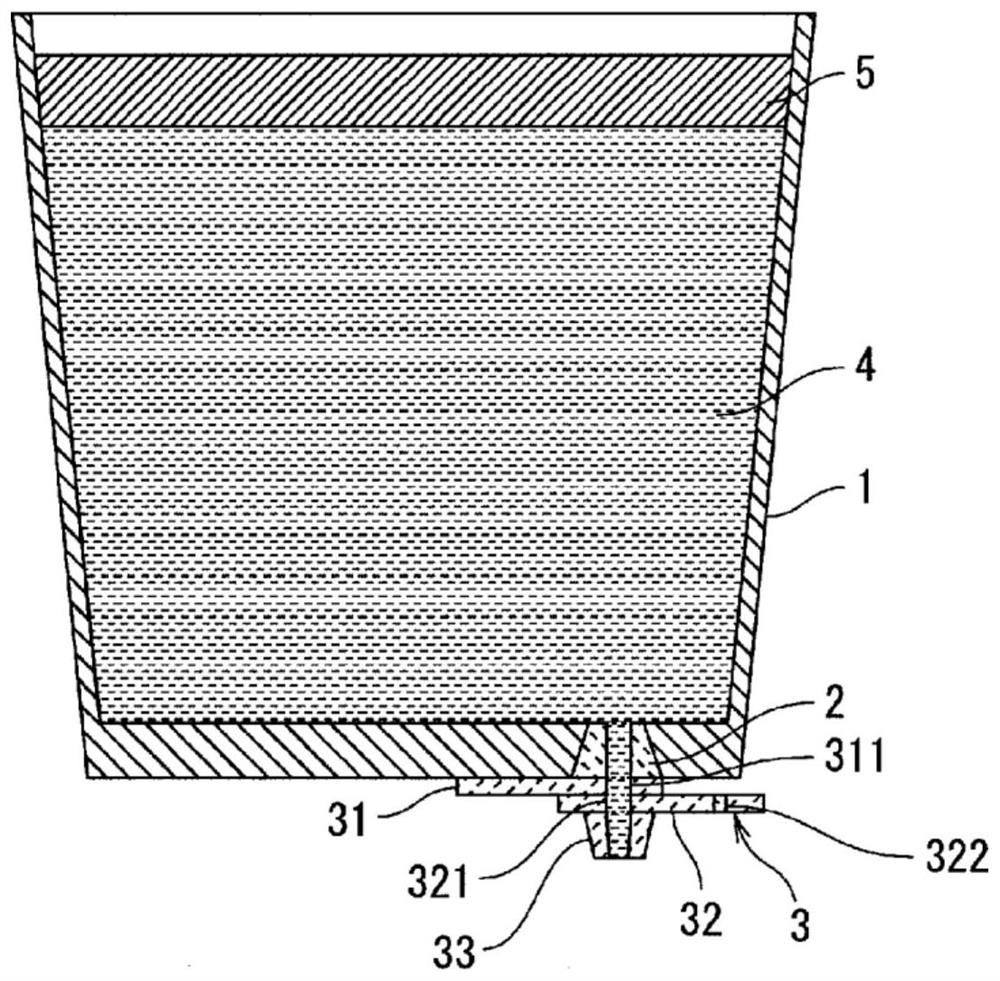

[0069] In embodiment 1, the filling amount of using molten steel 4 is 190t, and the nozzle diameter of upper nozzle 2 is 70mm (nozzle sectional area 3.8×10 -3 m 2 ) of ladle 1 were investigated.

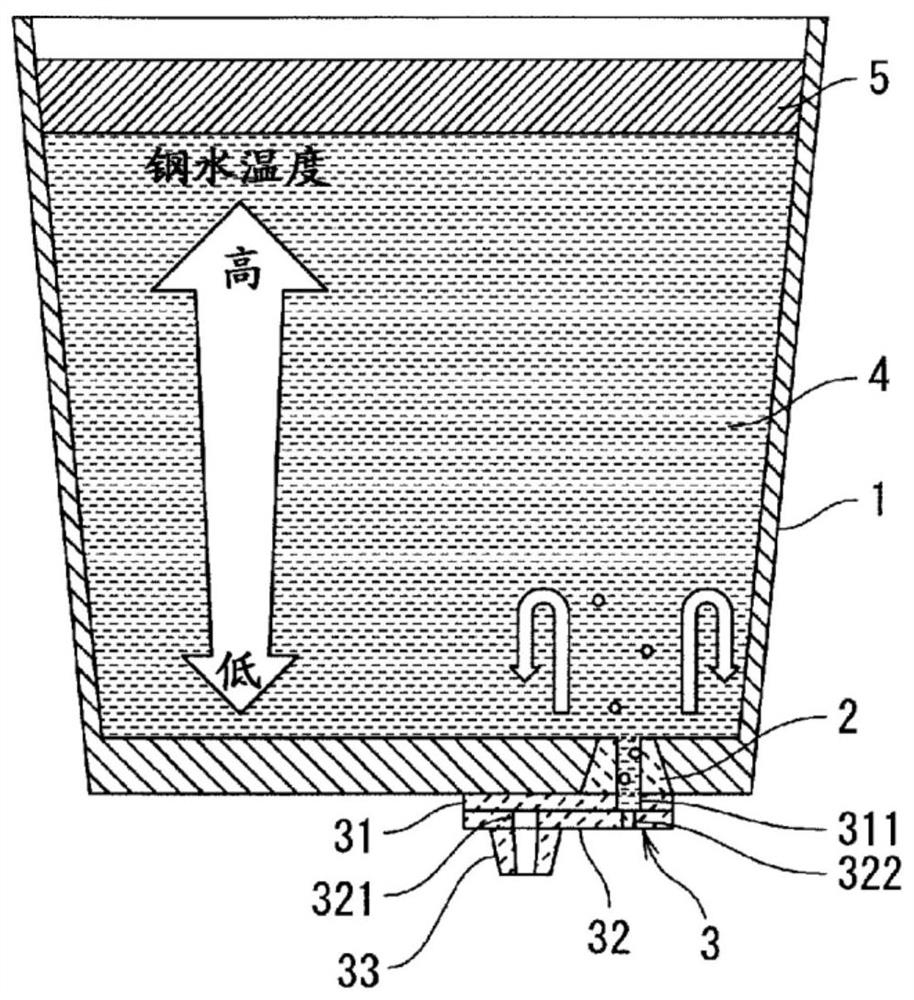

[0070] In Embodiment 1, in the pouring process, the sliding plate 32 is placed in the open position for 7 seconds, and the drainage sand and molten steel are poured out. Thereafter, the slide plate 32 is returned to the closed position, and Ar gas is blown into the molten steel 4 in the ladle 1 from the gas injection hole 322 through the first injection hole 311 . The flow rate of Ar gas is set to 30.0NL / min (7.8Nm 3 / (min·m 2 )).

[00...

Embodiment 2

[0074] In Example 2, before the investigation, the homogeneous mixing time under the conditions of the actual machine was calculated. As the calculation condition, the temperature T of molten steel 4 1 Set as 1827(K), the weight W of molten steel 4 is set as 190t, the blowing depth (bath depth) h v Set to 2.29m, set the atmospheric pressure P a Set to 0.1MPa, set the standard state temperature T 0 Set to 300K, set the bath diameter d v Set to 3.375m. Show the calculation results in Figure 7 . Such as Figure 7 As shown, it can be confirmed that 1 / 4 of the homogeneous mixing time is 61.0 s when the blowing flow rate of Ar gas under actual machine conditions is 30.0 NL / min.

[0075] Next, in Example 2, based on the above results, continuous casting of molten steel was performed with 1 / 4 of the homogeneous mixing time set to 61.0 s, and the success rate of re-drilling was investigated. It should be noted that in Example 2, the continuous casting of molten steel 4 was carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com