Submerged hollow fiber membrane element, membrane module, membrane module system and preparation method

A fiber membrane, immersion technology, applied in the field of sewage treatment equipment, can solve the problems of inconvenient installation and maintenance, complex production process, low production efficiency, etc., and achieve the effects of convenient transportation, improved cleaning effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

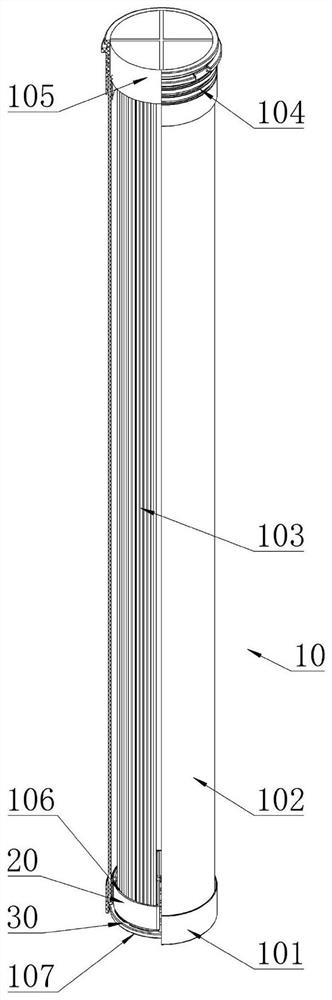

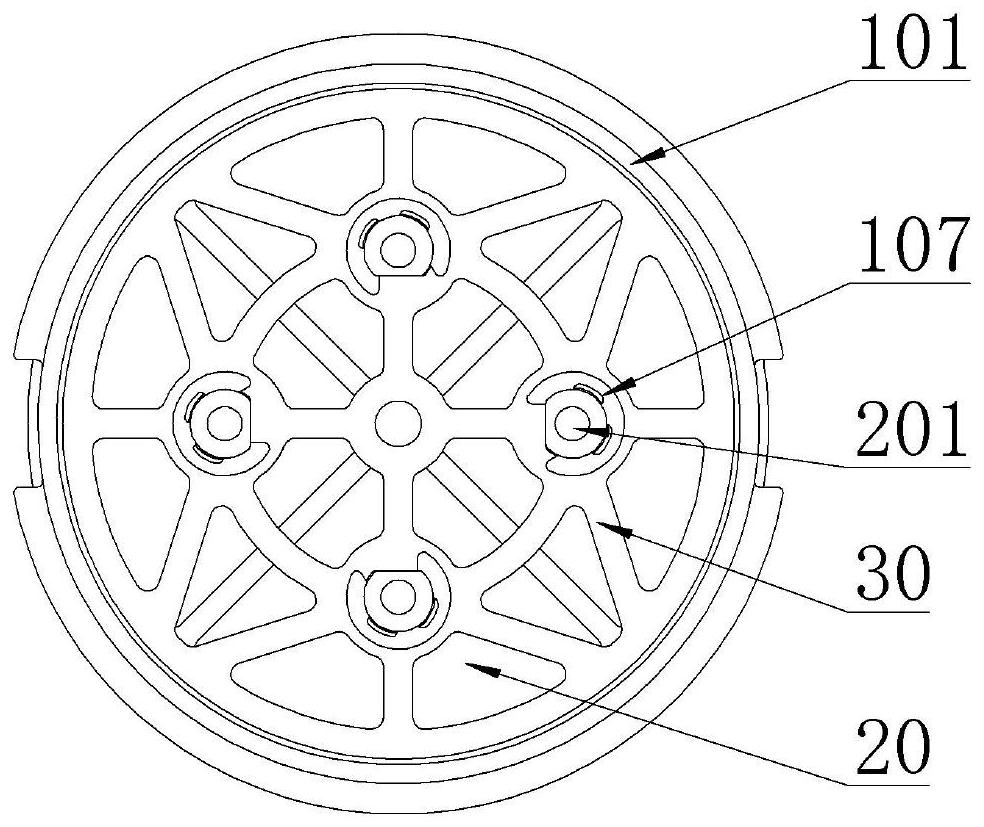

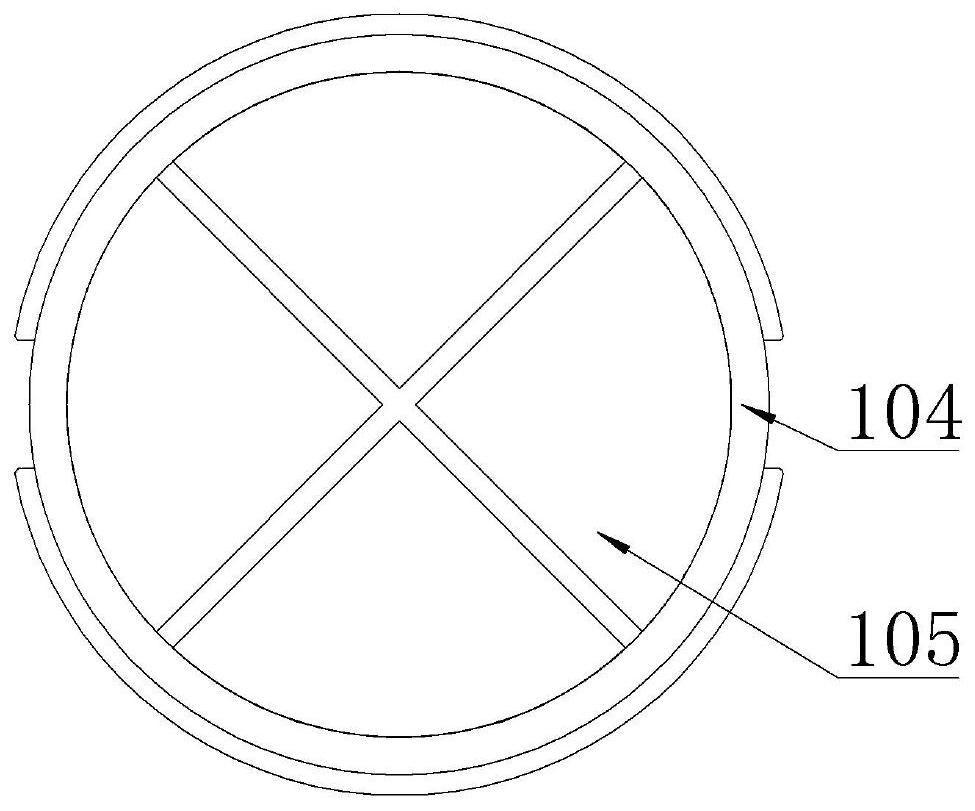

[0051] see Figure 1-Figure 5 A submerged hollow fiber membrane element 10 comprises a lower end cover 101, a membrane case 102, a plurality of hollow fiber membrane filaments 103, an upper end cover 104, an upper end sealing and fixing layer 105 and a plurality of lower end sealing and fixing layers 106; The upper and lower ends of the membrane shell 102 are respectively fixed with an upper end cover 104 and a lower end cover 101; inside the lower end cover 101, a positioning baffle 30, a plurality of injection membrane boxes 20 and a plurality of fixing rings 107 are arranged. The positioning baffle 30 floats inside the lower end cover 101, and each of the injection membrane boxes 20 is assembled and positioned with the positioning baffle 30 through the fixing ring 107 and can slide up and down; Hollow fiber membrane filaments 103, the plurality of hollow fiber membrane filaments 103 are evenly divided into multiple hollow fiber membrane filament bundles, and the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com