Sampling device for raw material processing of chemical experiment

A sampling device and experimental technology, applied in the direction of sampling device, feeding device, sampling, etc., can solve the problems of low efficiency, inconvenient disassembly and assembly, inaccurate sampling and detection data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Aiming at the deficiencies in the prior art, the present invention provides a sampling device for processing raw materials for chemical experiments, so that the raw materials for chemical experiments are not easy to accumulate at the bottom, the residence time of raw materials for chemical experiments at the bottom can be shortened, and the efficiency of raw materials for chemical experiments is improved. Mixing rate, multiple samplers can perform multi-layer sampling, which has the advantages of safety, high efficiency and accurate sampling and detection results.

[0030] In order to solve the problems of the technologies described above, the present invention adopts the following technical solutions:

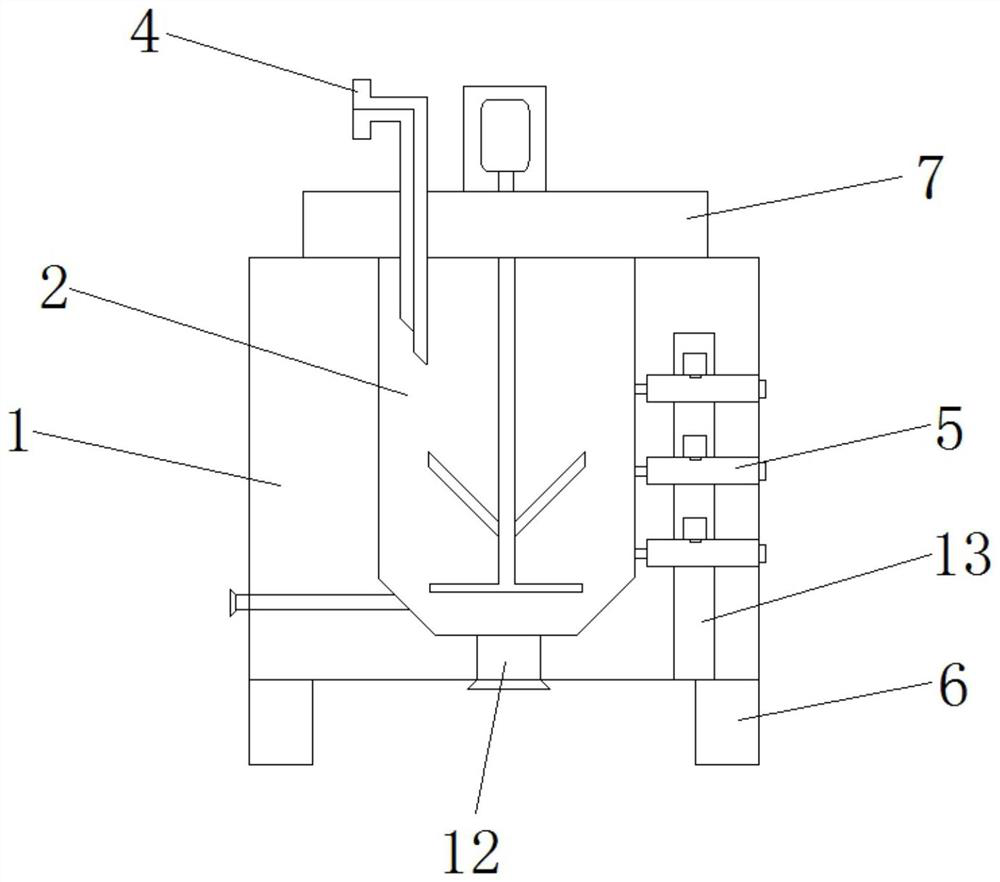

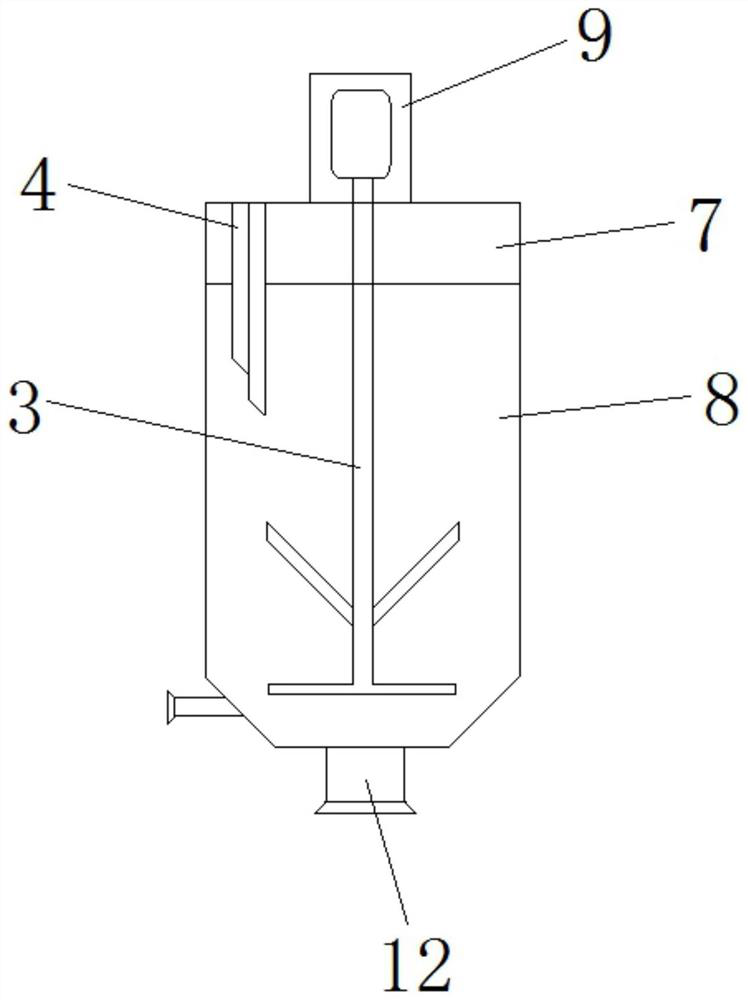

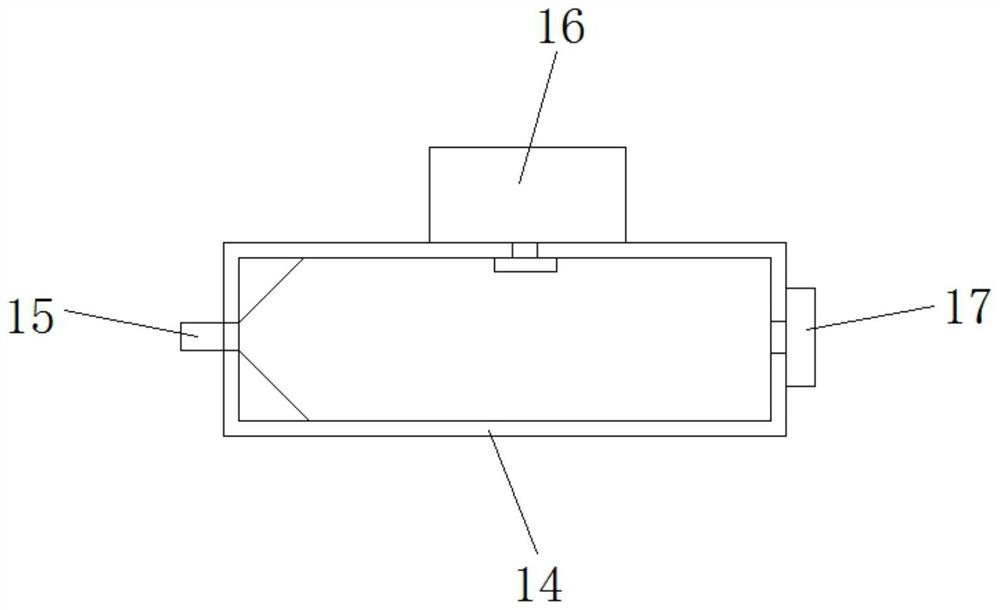

[0031] As an implementation, such as figure 1 As shown, a sampling device for raw material processing in a chemical experiment comprises a housing 1, a stirring tank 2, a stirring rod 3, an infusion tube 4 and a sampler 5; the housing 1 is in the shape of a cuboid, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com