Method for preparing diethyl chlorophosphite

A technology of diethyl chlorophosphite and triethyl phosphite, which is applied in the field of preparing diethyl chlorophosphite, can solve the problems of low reaction yield, adding catalyst and the like, so as to simplify the operation process and improve the product content , the effect of reducing the cost of synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

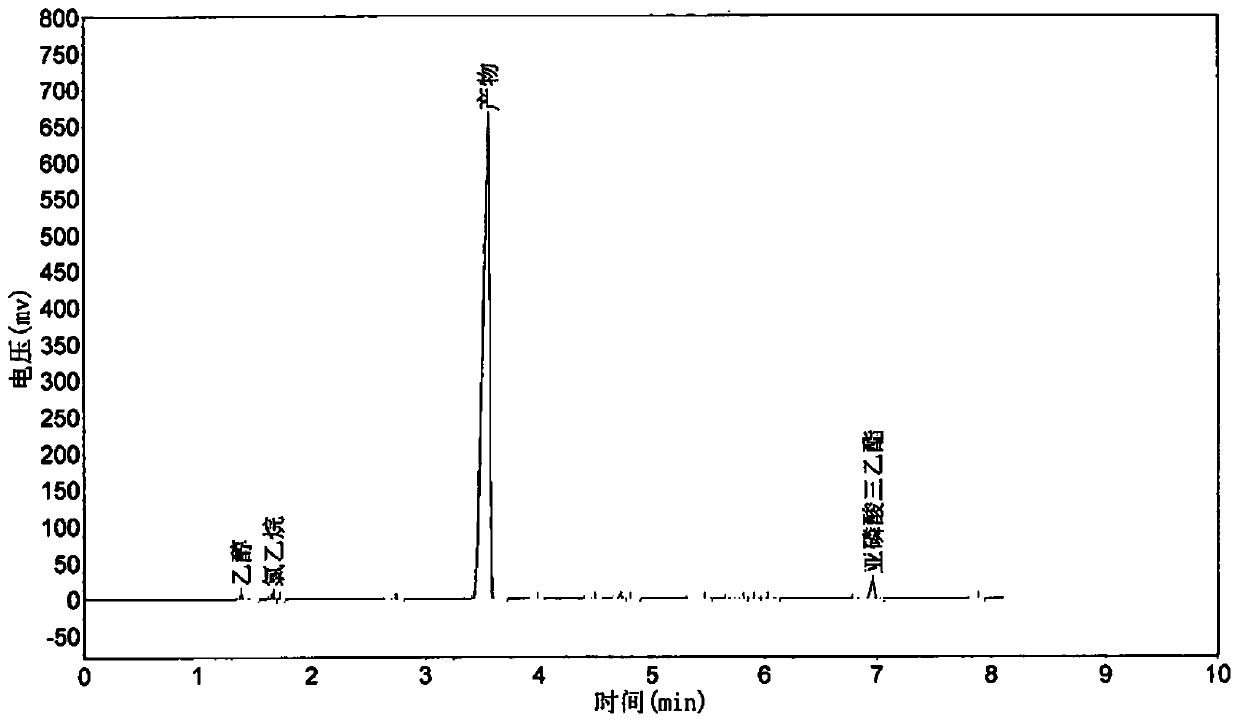

Embodiment 1

[0029] A method for preparing diethyl chlorophosphite, the specific synthesis steps are as follows:

[0030] Microchannel reactor model: RMCS1010, single-chip reaction unit liquid holding capacity 0.75mL, pipeline and joint liquid holding capacity 2.9mL; two infusion pump models: PF100 semi-preparative medium-pressure infusion pump.

[0031] (1) 500 g of triethyl phosphite is continuously delivered to the pre-cooling module A of the microchannel reactor, and the temperature of the triethyl phosphite is controlled to be 10° C., and the pre-cooling module A is connected to the channel A;

[0032] (2) 207g of phosphorus trichloride is delivered to the pre-cooling module B, and the temperature of the phosphorus trichloride is controlled to be 10° C.; the pre-cooling module B is connected to the channel B; the channel A and the channel B are respectively connected to the reaction module;

[0033] (3) open channel A and channel B, adjust the triethyl phosphite feeding pump flow rate...

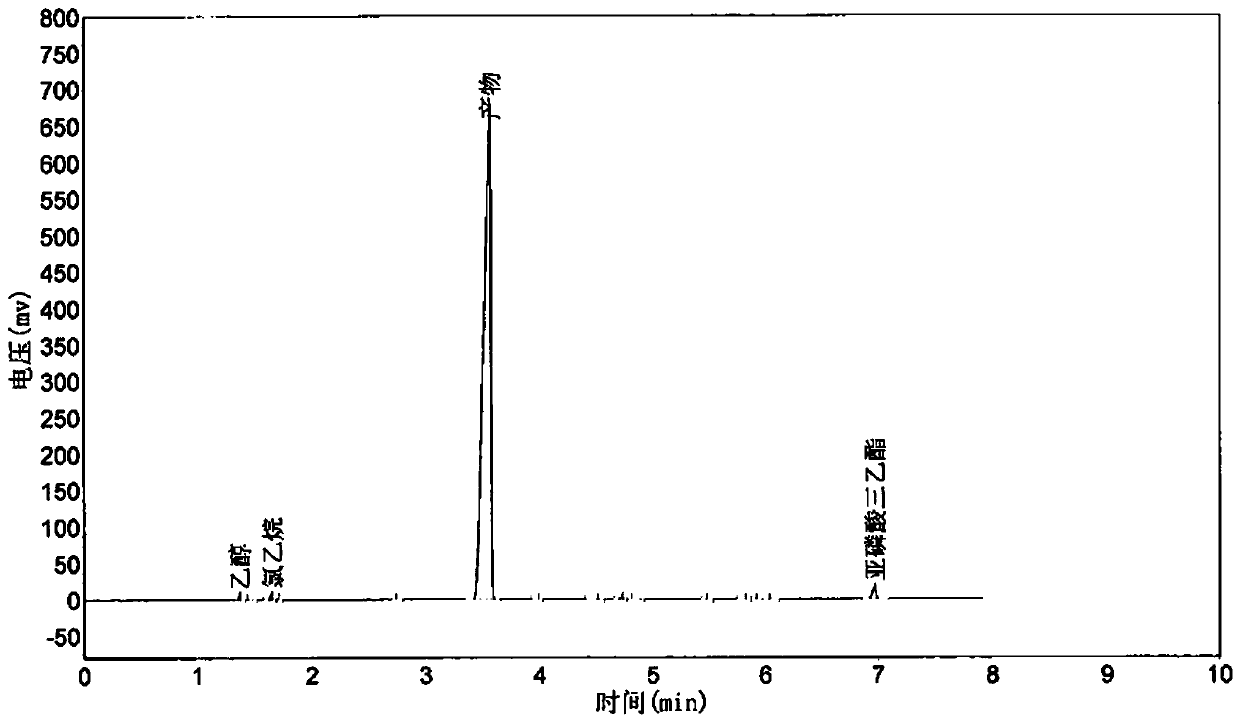

Embodiment 2

[0038] A method for preparing diethyl chlorophosphite, the specific synthesis steps are as follows:

[0039] Microchannel reactor model: RMCS402, single-chip reaction unit liquid holding capacity 9.2mL, pipeline and joint liquid holding capacity 7.8mL; two infusion pump models: PF100 semi-preparative medium-pressure infusion pump.

[0040] (1) 10 kg of triethyl phosphite is continuously delivered to the pre-cooling module A of the microchannel reactor, and the temperature of the triethyl phosphite is controlled to be 0° C., and the pre-cooling module A is connected to the channel A;

[0041] (2) 4.13 kg of phosphorus trichloride is delivered to the pre-cooling module B, and the temperature of the phosphorus trichloride is controlled to be 0° C.; the pre-cooling module B is connected to the channel B; the channel A and the channel B are respectively connected to the reaction module;

[0042] (3) open channel A and channel B, adjust the triethyl phosphite feeding pump flow rate ...

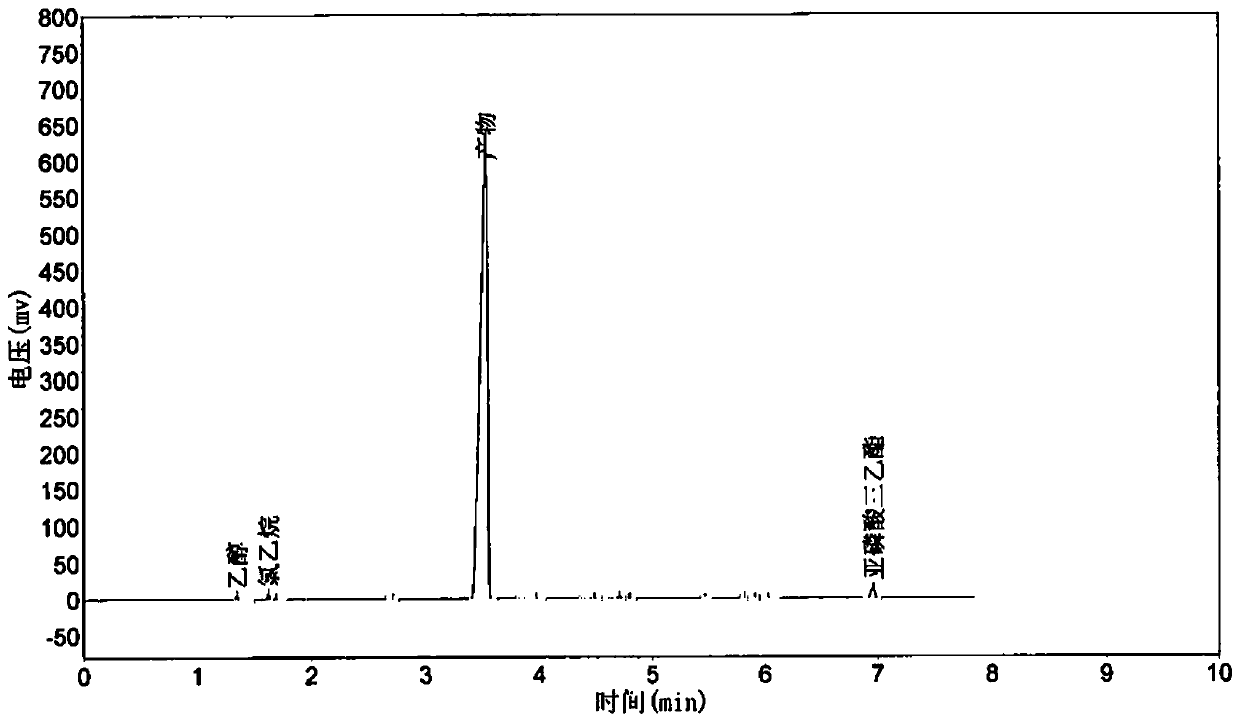

Embodiment 3

[0047] A method for preparing diethyl chlorophosphite, the specific synthesis steps are as follows:

[0048] Microchannel reactor model: RMCS402, single-chip reaction unit liquid holding capacity 9.2mL, pipeline and joint liquid holding capacity 7.8mL; two infusion pump models: PF100 semi-preparative medium-pressure infusion pump.

[0049] (1) 50kg of triethyl phosphite is continuously delivered to the pre-cooling module A of the microchannel reactor, and the temperature of the triethyl phosphite is controlled to be -5°C, and the pre-cooling module A is connected to the channel A;

[0050] (2) 20.66 kg of phosphorus trichloride is delivered to the pre-cooling module B, and the temperature of the phosphorus trichloride is controlled to be -5°C; the pre-cooling module B is connected to the channel B; the channel A and the channel B are respectively connected to the reaction module;

[0051] (3) open channel A and channel B, adjust the triethyl phosphite feeding pump flow rate to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com