High-moisture-retention polyquaternium copolymer production equipment

A polyquaternium salt and production equipment technology, which is applied in the field of high moisturizing polyquaternium salt copolymer production equipment, can solve the problems of incomplete reaction, low stirring efficiency, low product quality and the like, so as to improve output quality and production efficiency , Improve mixing efficiency, improve the effect of mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

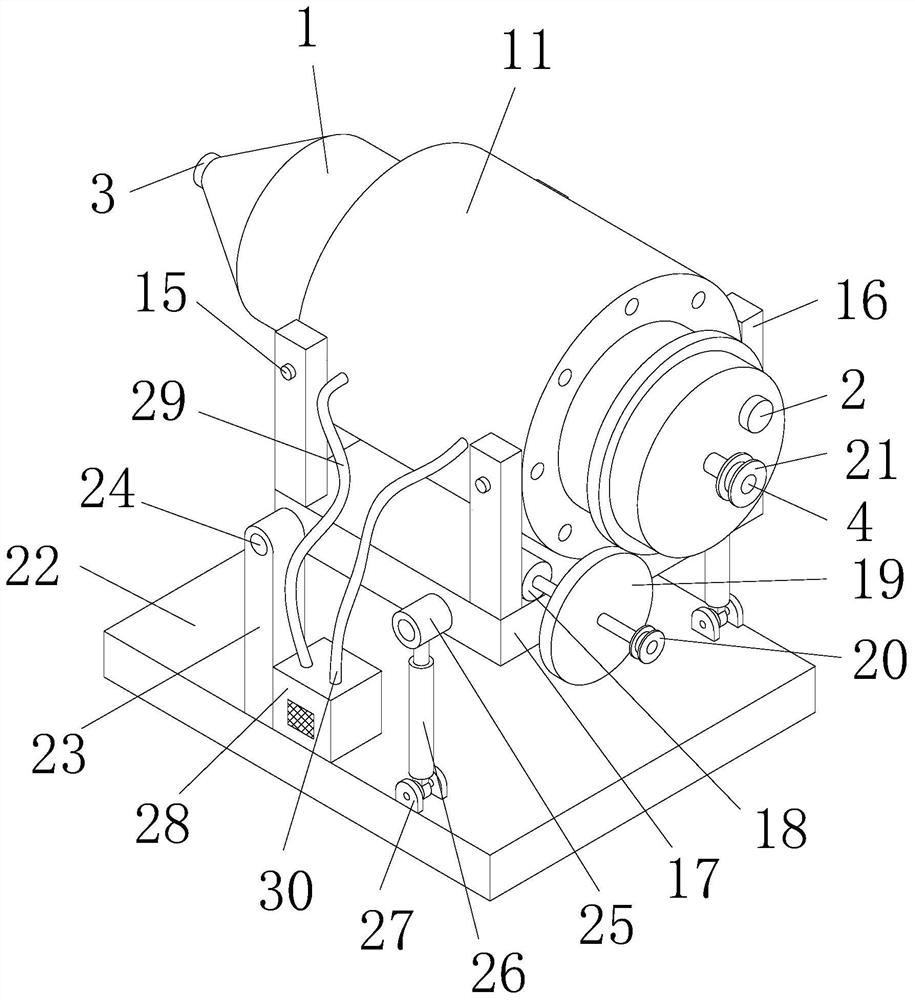

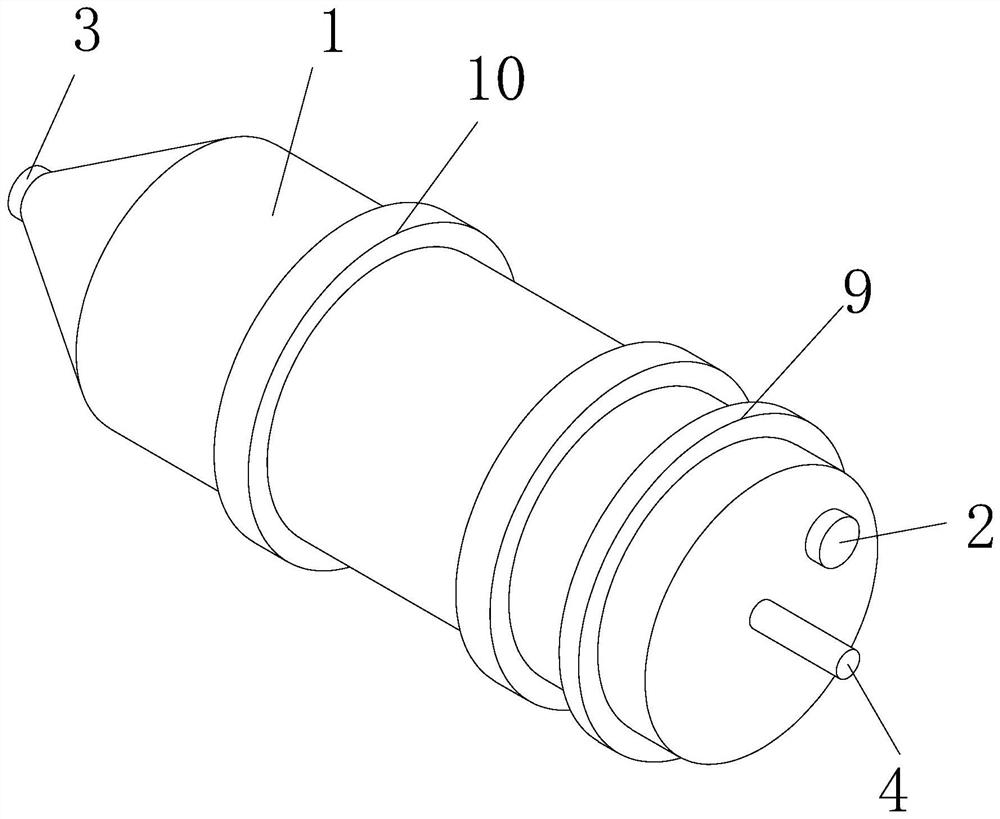

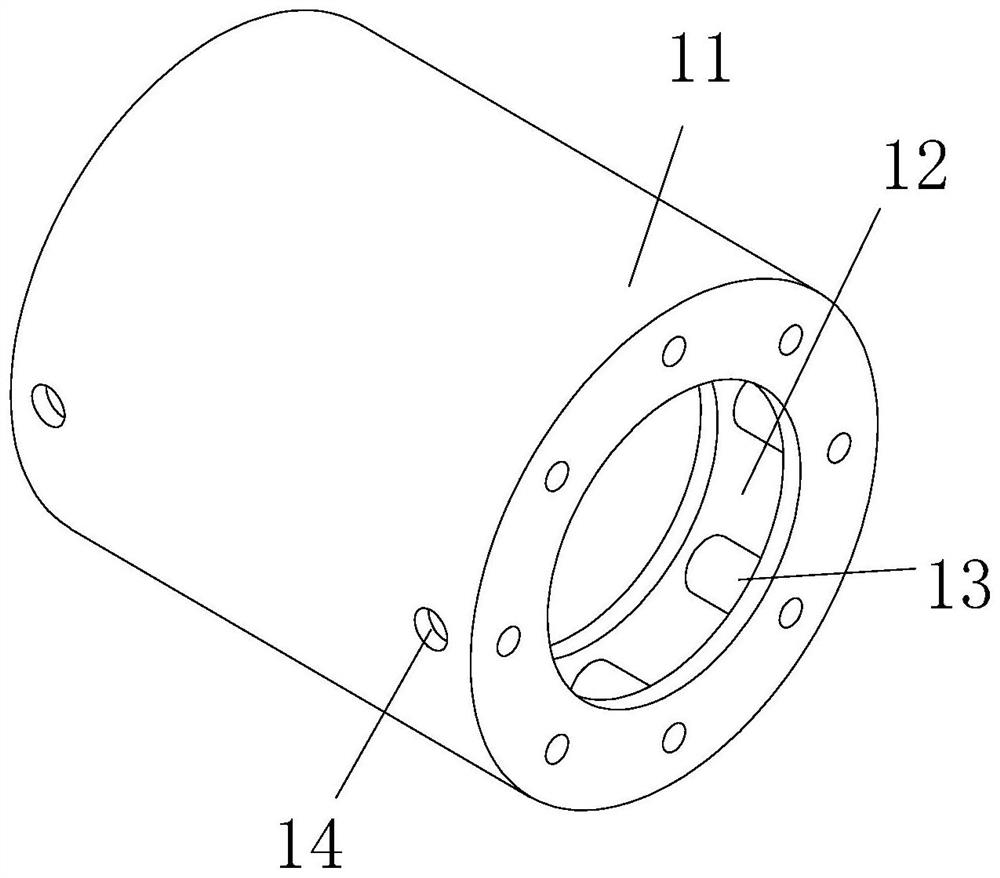

[0030] Embodiment: high moisture retention polyquaternium copolymer production equipment, such as figure 1 - Figure 4 As shown, the stirred reactor body 1 is included, the front of the stirred reactor body 1 is provided with a material inlet 2, the back of the stirred reactor body 1 is provided with a discharge port 3, and the front center of the stirred reactor body 1 is movable into a Stirring shaft 4, the rear end of the stirring reaction kettle body 1 has a conical structure, and the outer wall of the stirring shaft 4 is provided with a stirring main rod 6 and a discharge scraper 8, and both the stirring main rod 6 and the discharging scraper 8 are located in the stirring reaction Inside the kettle body 1, an insulation sleeve 11 is arranged on the outer wall of the stirred reactor body 1. The insulation sleeve 11 is in an annular cylindrical structure. The inside of the insulation sleeve 11 is hollowed out, and the inner wall of the insulation sleeve 11 is wound with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com