Motor shaft conveying system

A technology of conveying system and motor shaft, which can be used in conveying objects, transportation and packaging, coating, etc., and can solve problems such as low operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

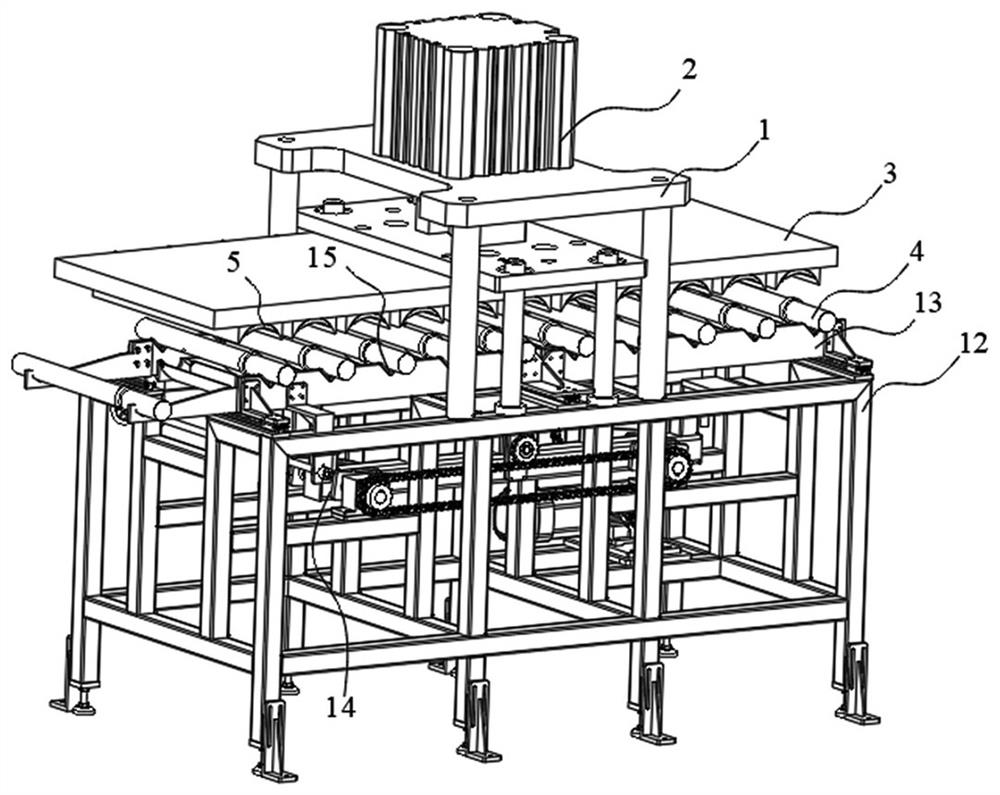

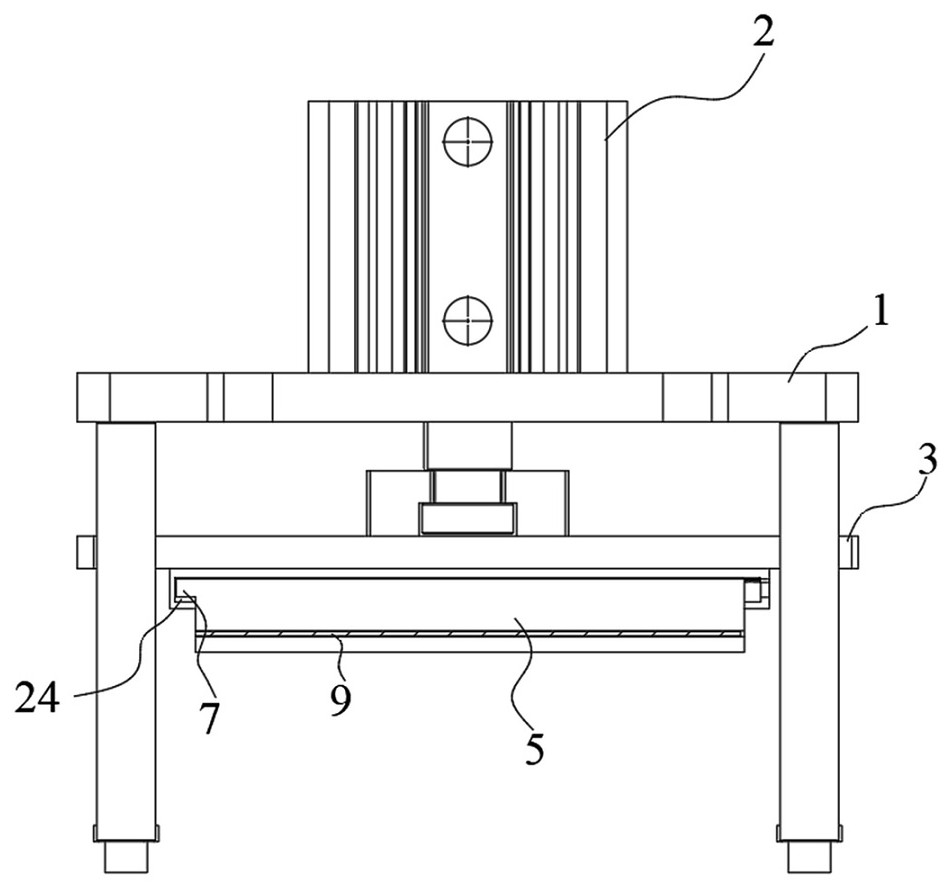

[0032] A motor shaft delivery systems, such as Figure 1 ~ 7 Shown, comprising: a bracket provided on the conveying means 1, the lifting stand 1 is provided on the greased mechanism and the drive mechanism for moving the wiping oil power down mechanism; wherein

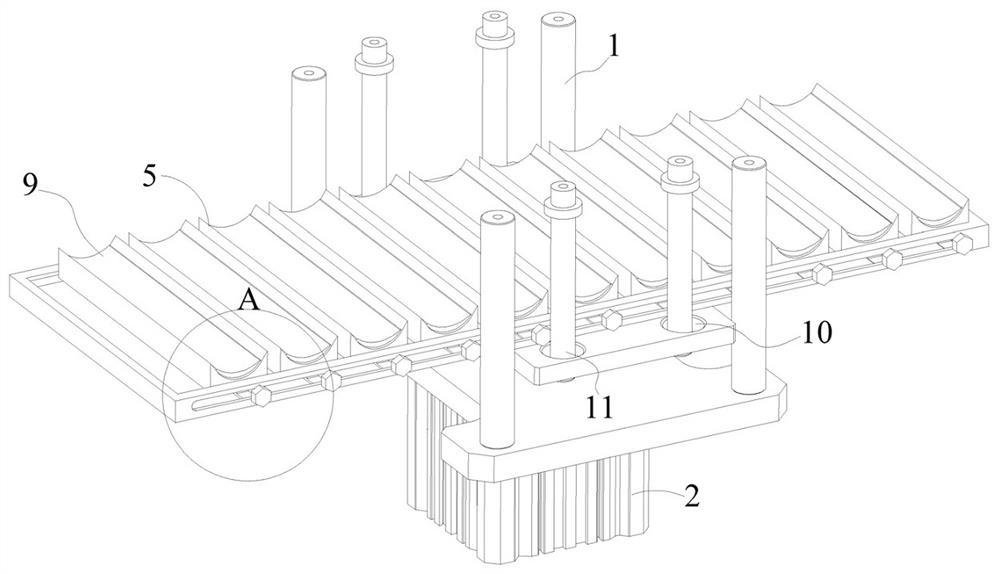

[0033]The oiling mechanism comprising means at said power drive mechanism can be in contact with the grease to the motor shaft 4, so that it deforms to wipe the oil occurs.

[0034] The oiling mechanism further includes a main body portion 3, cartridge oiled slides on the main body portion 3 of the bottom 5 and the coating disposed in said oil vessel (5) in the greased portion, wherein the oiled 4 position of the motor shaft position of the cartridge transporting mechanism 5, respectively. Oiled cartridge 5 can be slid on the main body portion 3, so as to adjust the position of the oil tank 5 of the coating, so that the final cartridge 5 the alignment oiled motor shaft 4. Means the size in the conveying motor shaft 4 may b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com