A kind of self-emulsifying softener and preparation method thereof

A softener and self-emulsifying technology, which is applied in the field of self-emulsifying softener and its preparation, can solve the problems of difficult production control and easy gelation, and achieve easy production control, easy preparation method, and good production process stability Effect

Active Publication Date: 2022-05-31

TAICANG BAONI IND CO LTD

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in this preparation method, due to the extremely high requirements of isocyanate on the content of water in the raw materials and the environment during the reaction, it is easy to gel and cause failure, and the production is difficult to control

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

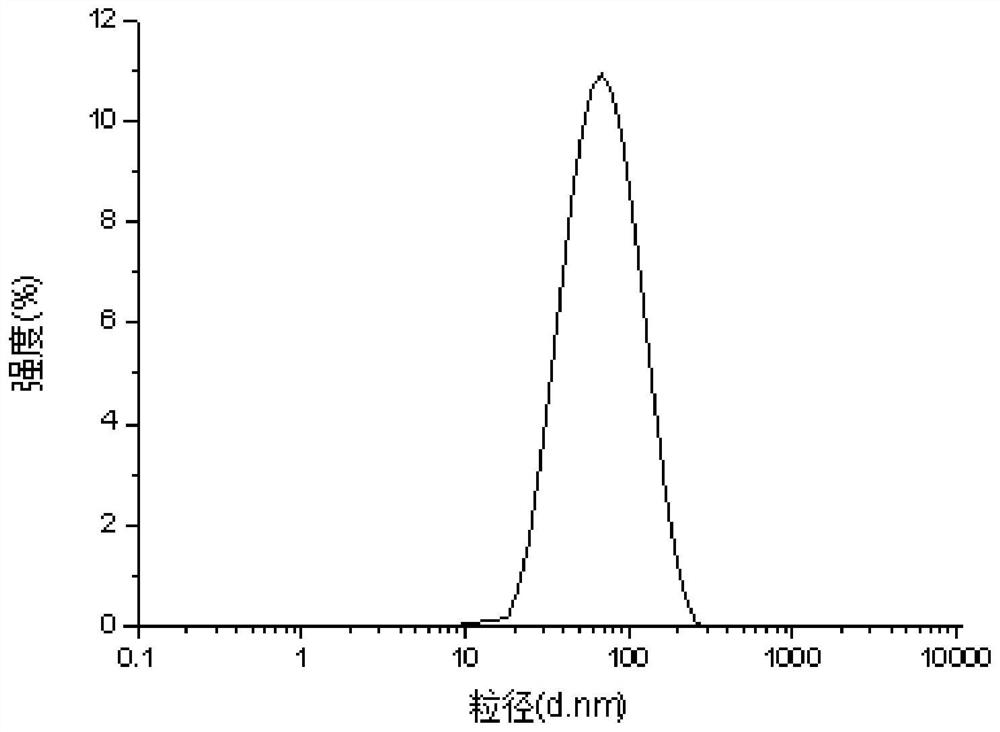

[0085] The weight-average molecular weight of the self-emulsifying softener 1 is 44,000. The particle size distribution is shown in Figure 1, and the average particle size (d.nm) is

Embodiment 2

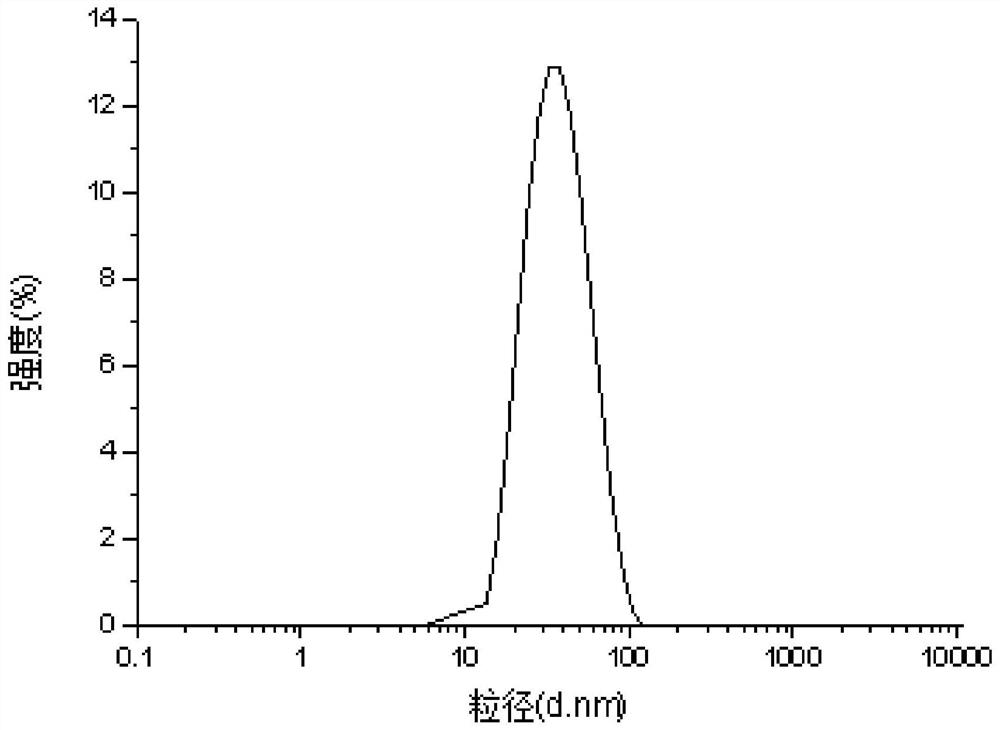

[0088] The weight-average molecular weight of the self-emulsifying softener 2 is 61,000. The particle size distribution is shown in Figure 2, and the average particle size (d.nm) is

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a self-emulsifying softener and a preparation method thereof, the self-emulsifying softener of the present invention is composed of formula (I), formula (II) and formula (III), wherein, m is an integer of 5-40; n is an integer from 1‑100; R 1 for H or CH 3 ; 2 for COOH or CH 2 CH(COOH) 2 . The self-emulsifying softener prepared by the invention does not contain solvent, has excellent application stability such as hand feeling, alkali resistance, high temperature resistance and electrolyte resistance, and is easy to control in production.

Description

A kind of self-emulsifying softener and preparation method thereof technical field The present invention relates to a kind of softener and preparation method thereof, particularly a kind of self-emulsifying softener and preparation method thereof Law. Background technique With the improvement of people's quality of life, the more comfortable and functional textiles are pursued, and the general textile printing and dyeing products After a series of chemical, physical and mechanical tension processing such as pretreatment, dyeing, etc., it will cause hand feeling problems such as hardening and stiffness. This will seriously affect the wearing performance of textiles. Therefore, softeners are often used for post-finishing to meet the requirements The desired feel. Silicone softening agent is a class of softening agent with wide application, good performance and outstanding effect on textiles. The particles are adsorbed on the fibers, which can greatly reduce the fri...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08F283/12C08F283/00C08F222/02C08F220/06D06M15/263

CPCC08F283/124C08F283/008D06M15/263D06M2200/50C08F222/02C08F220/06

Inventor 党婉蓉李正雄

Owner TAICANG BAONI IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com