Metal part surface electroplating treatment equipment based on machining

A technology for metal parts and electroplating treatment, which is applied in the direction of plating tanks, electrolytic processes, electrolytic components, etc., and can solve problems such as high cost of use, inability to replace by grades, and reduced cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

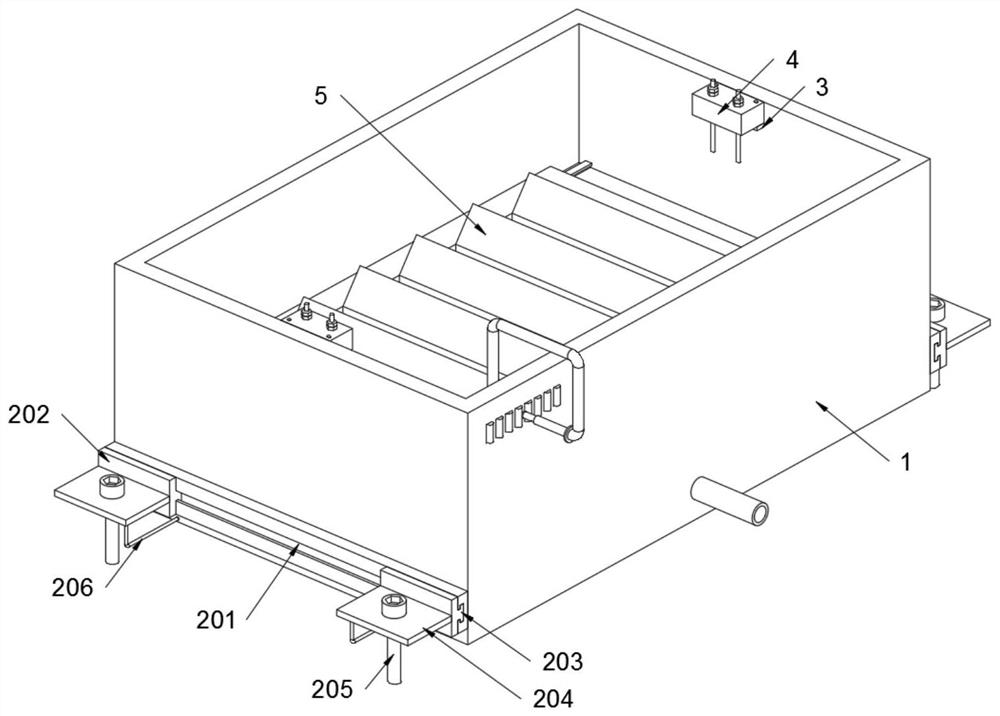

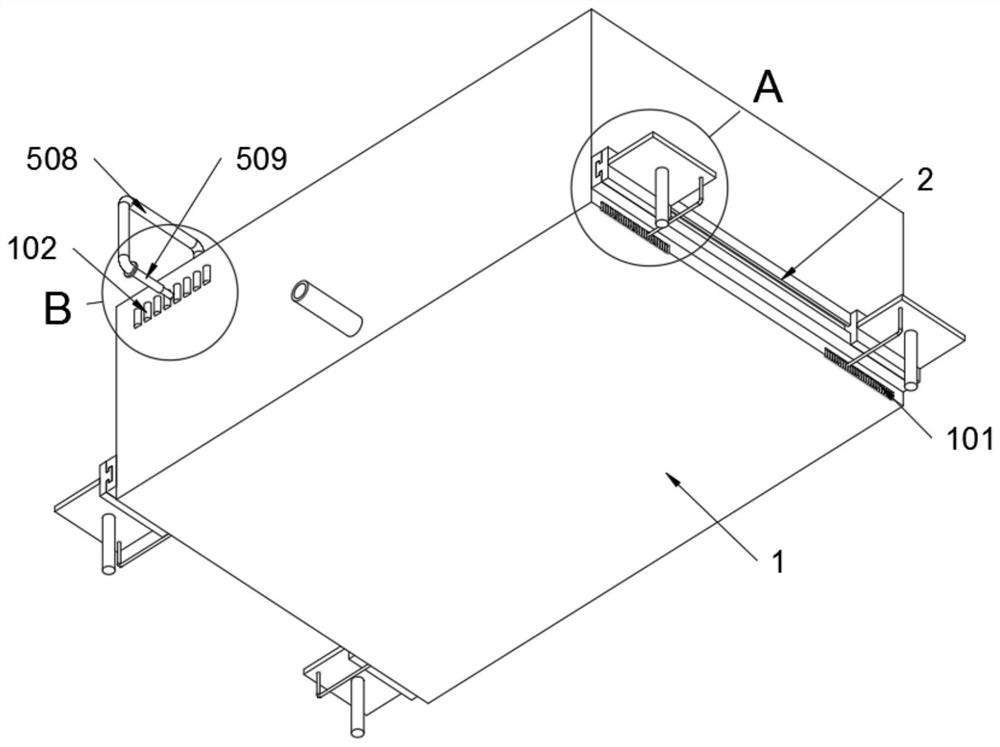

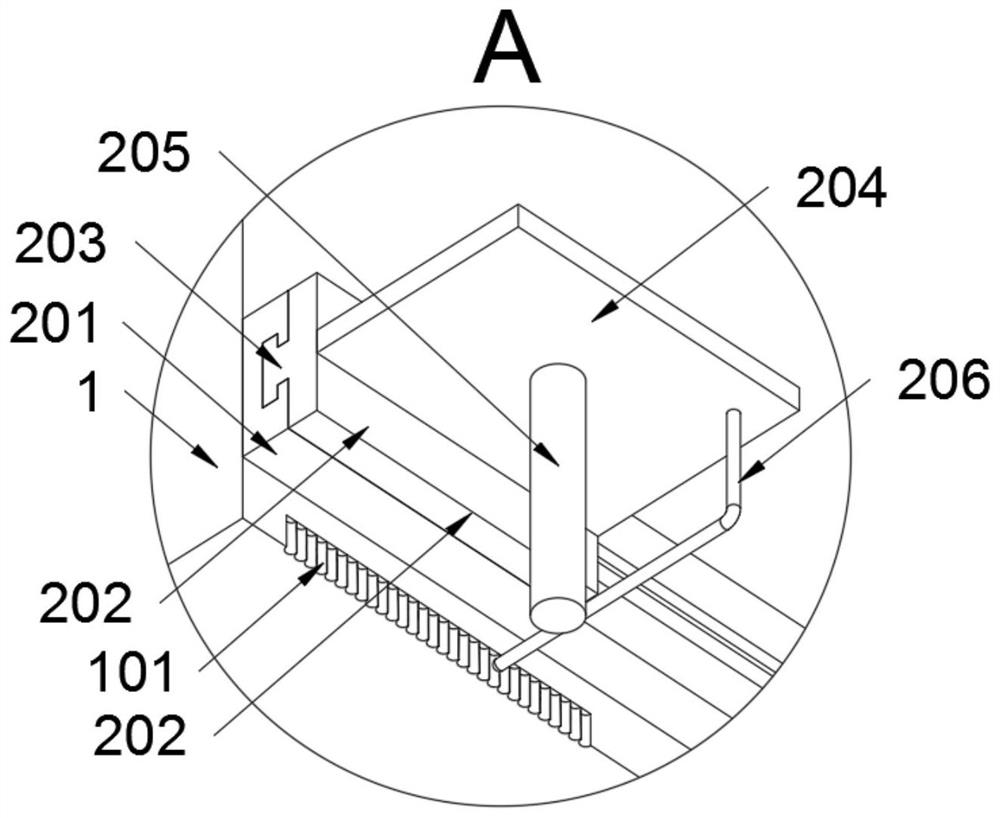

[0034] as attached figure 1 To attach Figure 8 Shown:

[0035]The present invention provides a surface electroplating treatment equipment for metal parts based on mechanical processing, which includes a box body 1; two fixing structures 2 are symmetrically welded on the box body 1, and two terminal fixing structures 3 are symmetrically welded on the box body 1 , and a terminal block 4 is installed on each terminal fixing structure 3; an auxiliary structure 5 is installed in the box body 1; refer to as figure 2 and image 3 , the box body 1 includes a card slot 101, the card slot 101 is opened on the box body 1 in a rectangular array, and the card slot 101 is a semi-cylindrical structure; the fixed structure 2 includes a limit arm 206, and the limit arm 206 is welded on the fixed plate 204, and the spacer arm 206 is a shape structure; the head end of the spacer arm 206 is a hemispherical structure, and the head end of the spacer arm 206 matches the draw-in groove 101; when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com