Energy-saving and environment-friendly device capable of improving non-woven fabric leveling effect

An energy-saving and environmentally friendly non-woven technology, applied in the field of textiles, can solve problems such as low steam flow rate, poor leveling effect, and small steam volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

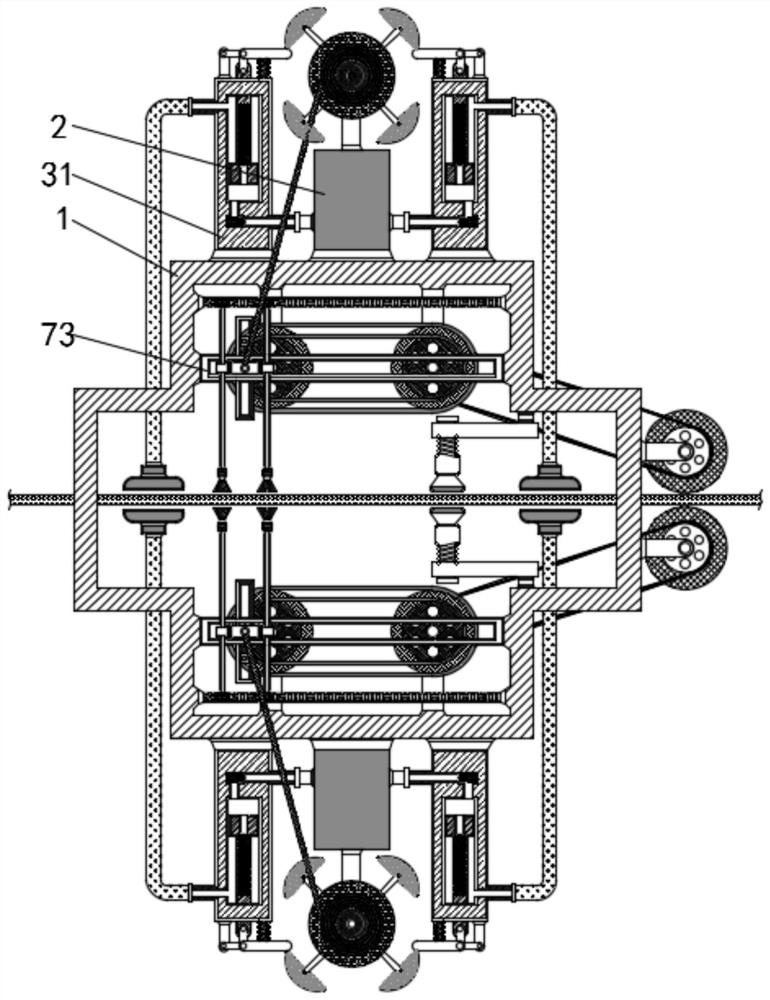

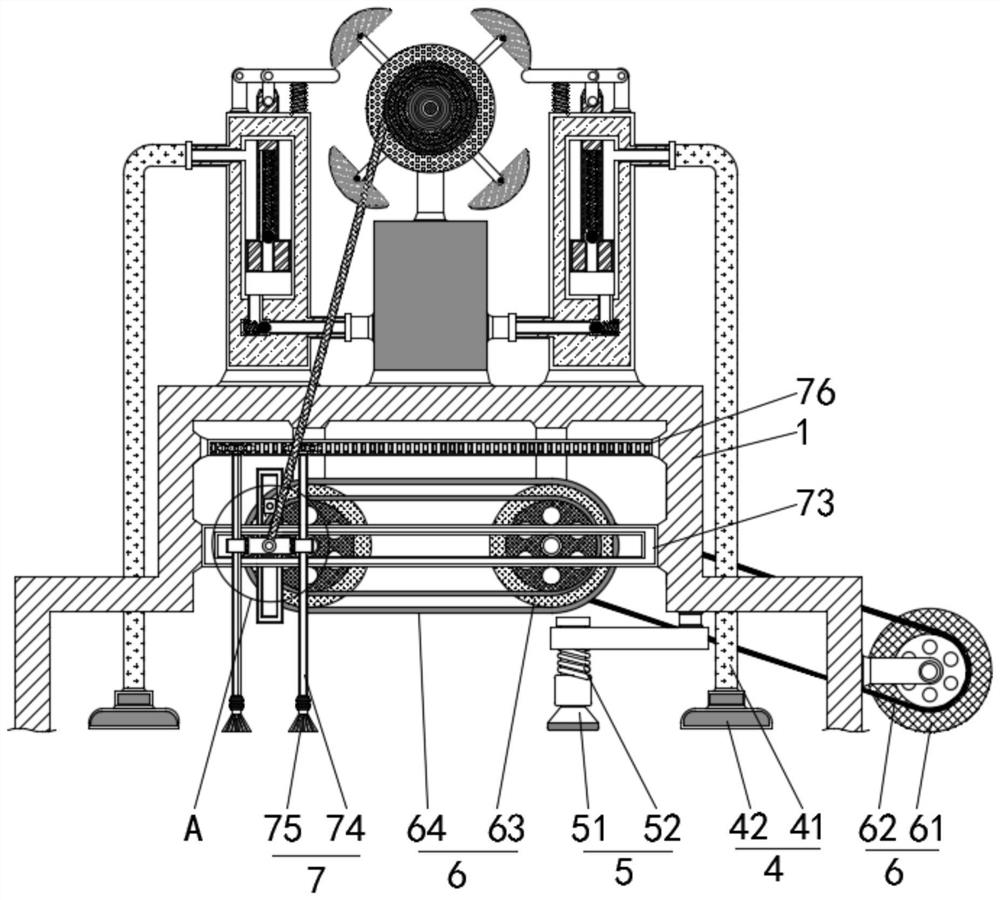

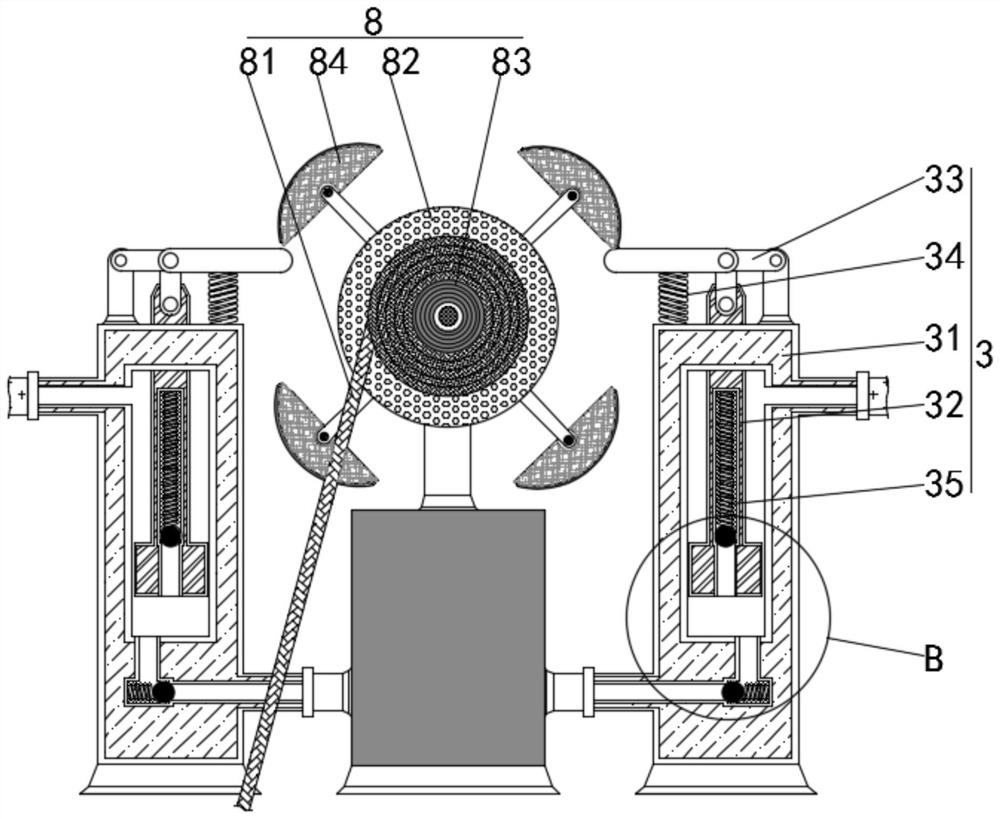

[0026] see figure 1 , figure 2 and Figure 5 , an energy-saving and environment-friendly device that can improve the leveling effect of non-woven fabrics, including a housing 1, a steam chamber 2 is fixedly connected to the outside of the housing 1, and transmission components 3 are arranged on the left and right sides of the steam chamber 2, and the transmission components 3 includes the intermediate station 31, the inner side of the intermediate station 31 is slidingly connected with the moving block 32, the upper side of the moving block 32 is connected with the connecting rod group 33, the right side of the transmission assembly 3 is fixedly connected with the air supply assembly 4, and the left side of the air supply assembly 4 The side is provided with a leveling assembly 5, the upper side of the leveling assembly 5 is provided with a drive assembly 6, the front side of the drive assembly 6 is slidingly connected with a cleaning assembly 7, and the front side of the cl...

Embodiment 2

[0031] The specific usage and function of this embodiment:

[0032] see Figure 1-5 , an energy-saving and environment-friendly device that can improve the leveling effect of non-woven fabrics, including a housing 1, a steam chamber 2 is fixedly connected to the outside of the housing 1, and transmission components 3 are arranged on the left and right sides of the steam chamber 2, and the transmission components 3 includes the intermediate station 31, the inner side of the intermediate station 31 is slidingly connected with the moving block 32, the upper side of the moving block 32 is connected with the connecting rod group 33, the right side of the transmission assembly 3 is fixedly connected with the air supply assembly 4, and the left side of the air supply assembly 4 The side is provided with a leveling assembly 5, the upper side of the leveling assembly 5 is provided with a drive assembly 6, the front side of the drive assembly 6 is slidingly connected with a cleaning ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com