Windproof high-rise steel structure vertical correction device

A correction device and steel structure technology, applied in building construction, processing of building materials, measuring fixed angles, etc., can solve problems such as large errors, complicated loading and unloading, and complicated measurement operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

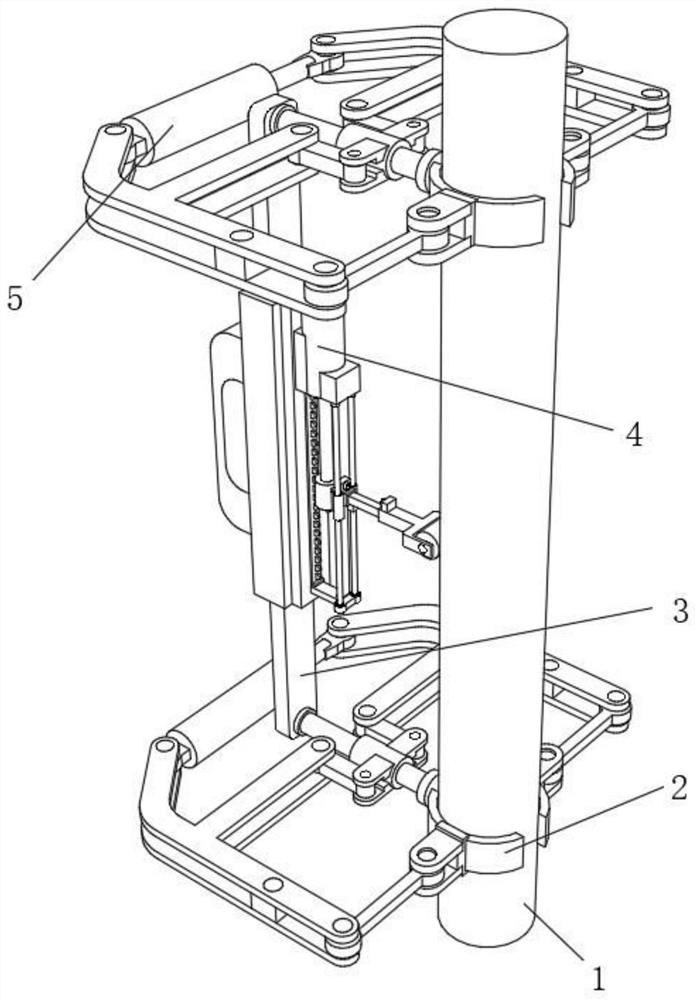

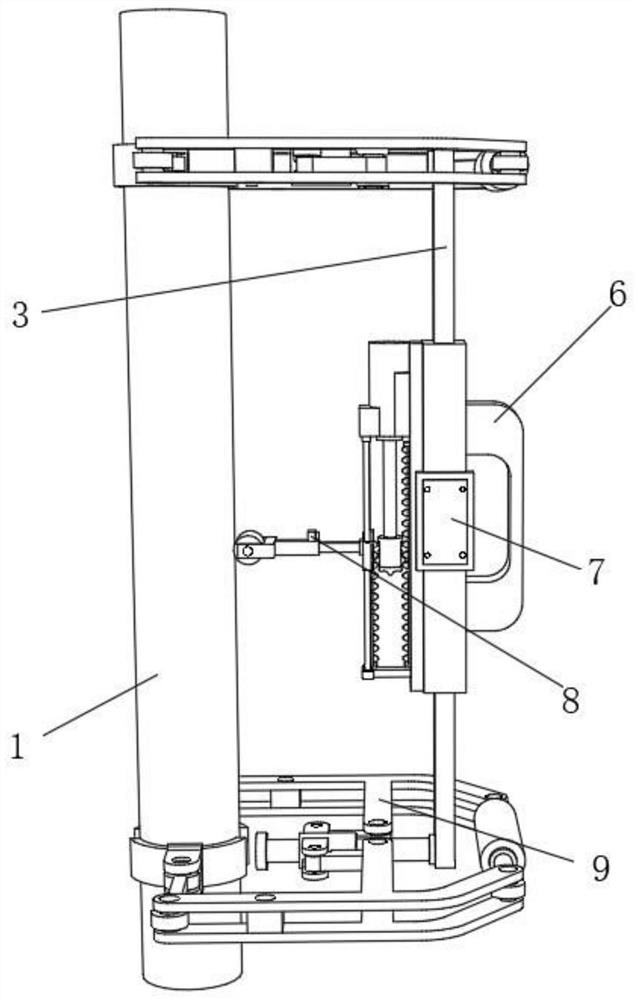

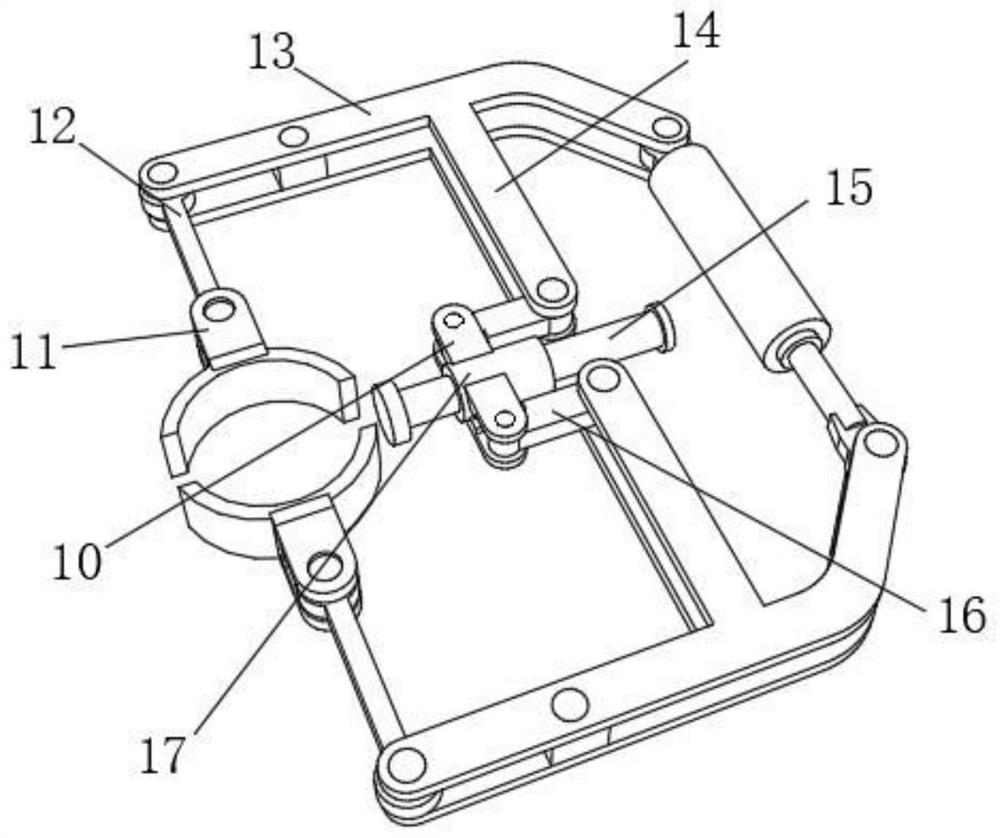

[0033] A wind-resistant high-rise steel structure vertical correction device, such as Figure 1-4 As shown, two clamping mechanism 9, two of the clamping mechanism 9 outputs two card ring 2 by bolts, and four snaps 2 cards have the same steel column 1, two clamping The partially retractable rod 3 is fixed to the side of the mechanism 9, and the end portion of the telescopic rod 3 is provided with a verticality rolling measuring mechanism, the output end of the verticality rolling measuring mechanism is provided with a roller 23, vertically rolling measuring mechanism. On the side, the distance sensor 8 is fixed by the bolt, and the outer wall of the retracting rod 3 is fixed by the bolt, and the outer wall of the telescoping rod 3 is fixed by the bolt 7.

[0034] When the handle 6 is operated by the handle 6 causes the designated position, and the card ring 2 is brought into the top end and the bottom end of the steel column 1 by starting the two clamping mechanism 9, the verticali...

Embodiment 2

[0041] A wind-resistant high-rise steel structure vertical correction device, such as Figure 5 As shown, in order to facilitate the steel structural sheet; the present embodiment, the following improvements are made on the basis of the first embodiment: the roller 23 can be replaced with a support plate 25, and the outer walls of the support plate 25 have a weld groove, and The inner wall of each weld groove is welded to have a fixing cylinder 26, and each fixing tube 26 has a finite ring 27, and four rollers 24 are fixed by the support plate 25; the support will be supported by the limit ring 27. The plate 25 is fixed to the top end of the telescopic bracket 22 and causes the four rollers 24 of the support plate 25 against the steel structural sheet, and the two rollers 24 are moved along the steel sheet, which not only avoids the support plate 25 in the steel sheet. Direct contact friction and ensure the stability of the measurement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com