Construction method of flame-retardant support system for oil storage tank

A support system and construction method technology, which is applied in the construction field of flame-retardant support systems for oil storage tanks, and can solve problems such as high transportation costs, high accumulation density of pebbles, and lack of power transmission and transformation projects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

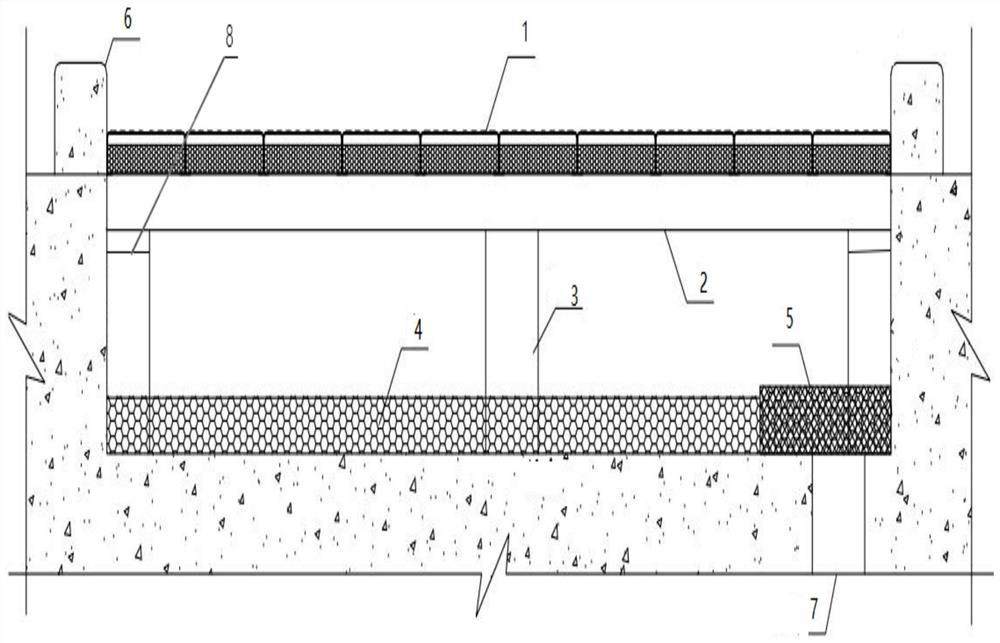

[0053] Please refer to figure 1 as shown, figure 1 It is a schematic diagram of the construction structure of the present invention.

[0054] This embodiment provides a construction method for a flame-retardant support system for an oil storage tank, which specifically includes:

[0055] S100, basic line marking steps:

[0056] S101: the step of determining the base surface, drawing a plane line at a position lower than the settlement observation point on the main transformer base wall of the oil storage tank 6, and drawing the base surface on the pool wall after the positioning is accurate; if there is no settlement observation point, Draw a plane line below the top wall of the oil storage tank 6; use a laser level to project the basic marking height to the pool wall, and then mark the entire pool wall; The installation position in the oil storage pool 6 and on the pool wall, and draw the base line of the installation position of the support in the oil storage pool 6 and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com