Exhaust and silencing assembly for high-power engine

An engine and high-power technology, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve problems such as abnormal use, unfavorable industrial assembly, and unreasonable force distribution of supports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

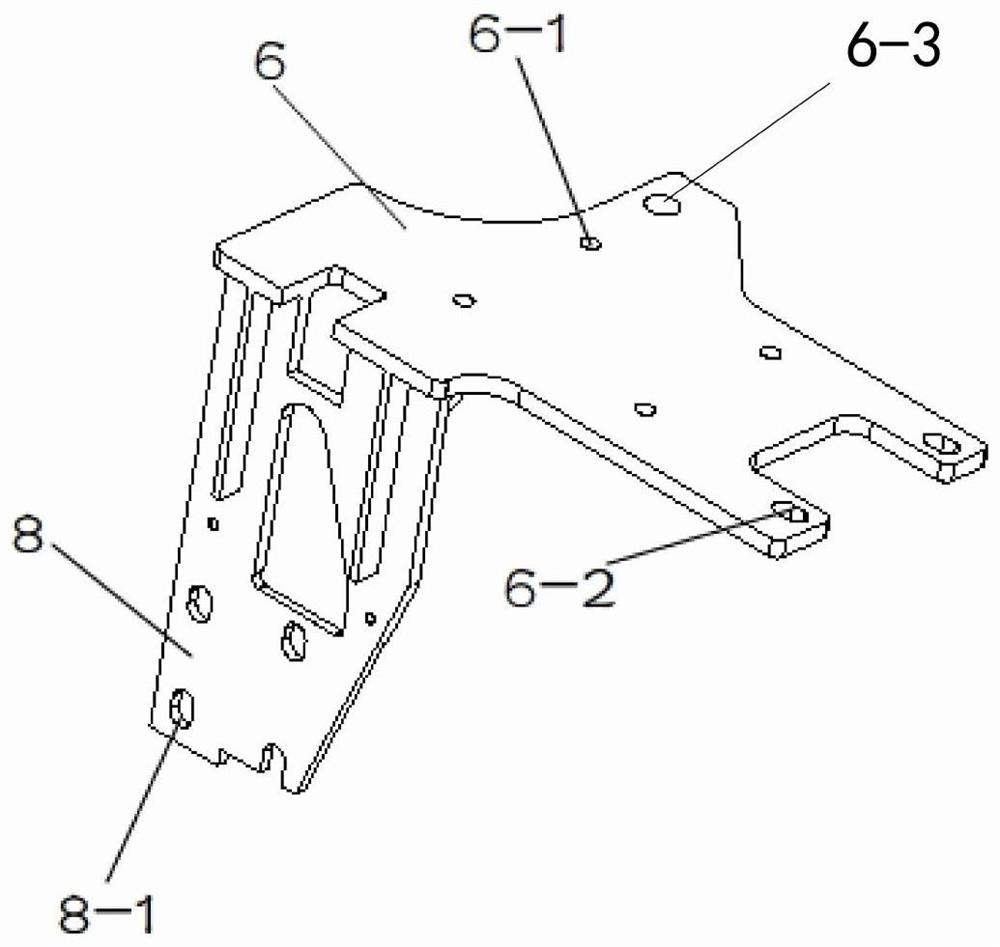

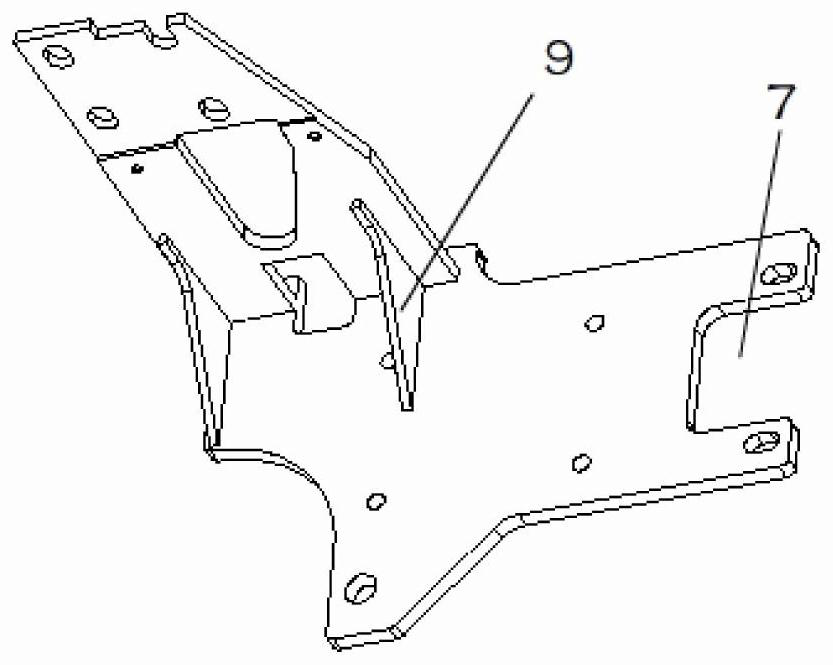

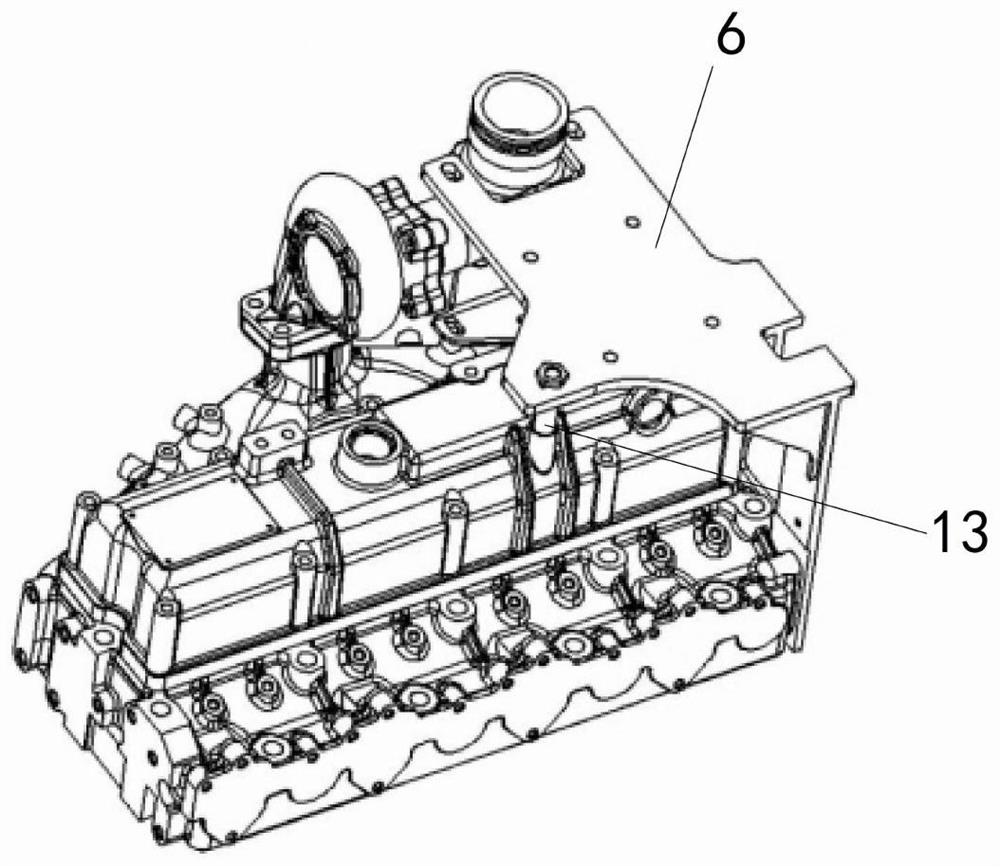

[0022] like Figure 1 ~ 7 As shown in a high-power engine exhaust muffler assembly, the muffler comprising a bracket, the exhaust pipe 10 and the semicircular clamp L-shaped exhaust pipe support base 11; the muffler support includes a support plate 6, the support plate 6 defines a number of the muffler fixing holes 6-1, which further defines a distal opening of the exhaust pipe 7 give way; lower left vertical side of the support plate 6 is fixed with a support plate 8 in combination, the support plate is fixed to the support between the plate 9 is provided with reinforcing plate. Right side of the support plate further defines a support hole 6-3, the support hole is provided with a corresponding support pillar 13, and the lower end of the support column 13 is connected and fixed to the engine block. Fixing the support plate defines a plurality of fixing holes 8 have 8-1; give way of the exhaust pipe slotted hole 7 on both sides of the port 6-2 is opened, the exhaust pipe 10 corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com