Fluid-heat network modeling and bidirectional coupling method for axial-radial mixed ventilation cooling motor

A ventilation cooling, two-way coupling technology, applied in electrical digital data processing, computer-aided design, special data processing applications, etc., can solve the problems of complex structure, limited calculation accuracy, and long calculation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

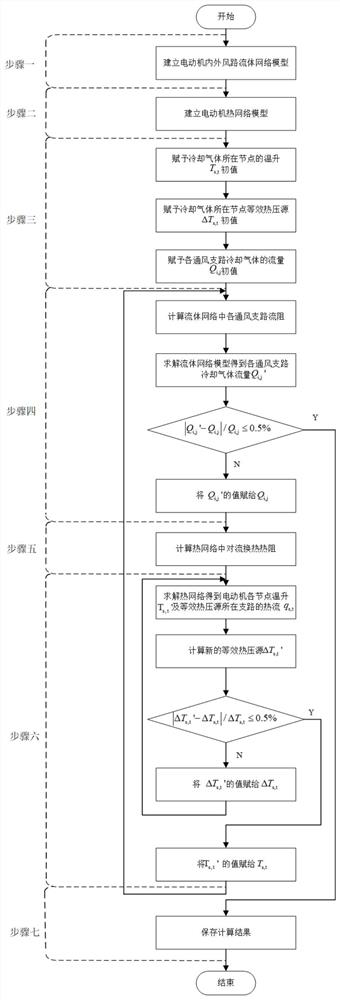

[0029]The fluid network and the thermal network interact with each other, and the change of the parameters of a single network model will not only affect the parameters of the other network model, but also have a tendency to offset the change of the original parameters on itself, so the two-way coupling calculation can get more accurate prediction of the whole domain of the motor Temperature rise distribution.

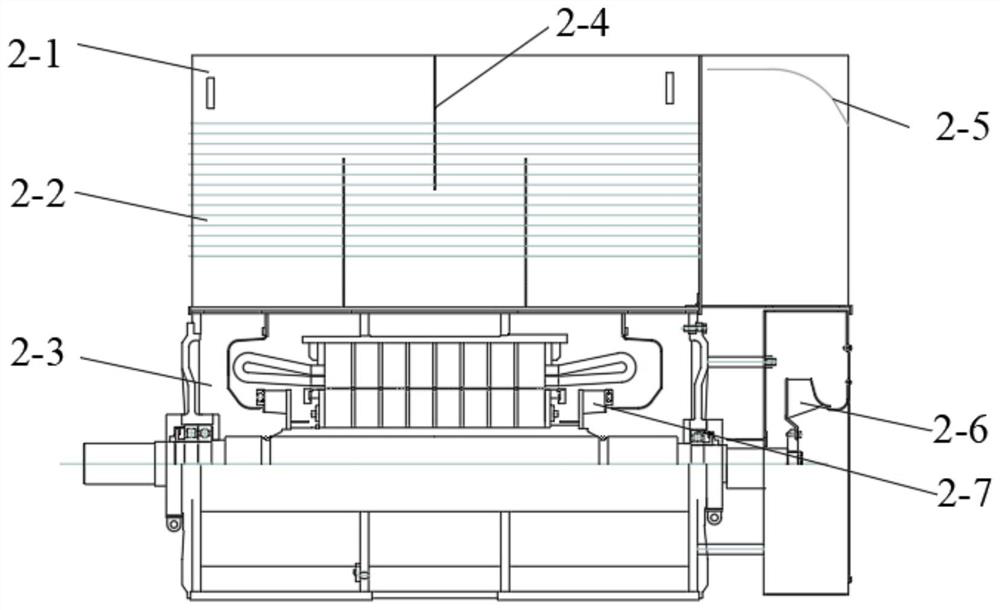

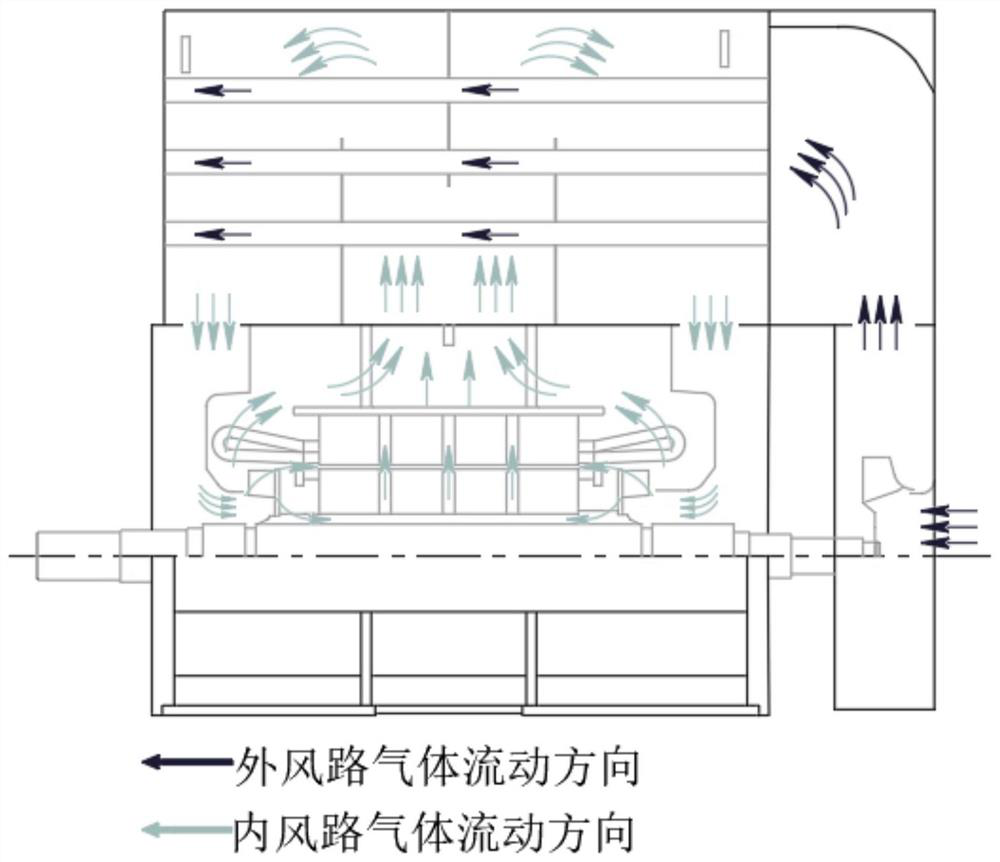

[0030] This example takes the axial and radial mixed ventilation motor as an example according to figure 1 The operation shown in the flow chart, this motor is air-air cooling, such as figure 2 shown. The internal cooling method of this motor is axial and radial mixed ventilation and cooling. Centrifugal fans are installed on both sides of the motor. Axial air passages are formed between the rotating shaft and the inner diameter of the rotor through supporting webs. The core of the main part of the motor is divided by 7 radial air passages. There are 8 sections, num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com