Permanent magnet motor rotor, permanent magnet motor and processing method of permanent magnet motor rotor

A technique for permanent magnet motors and processing methods, which is applied in the manufacture of motor generators, magnetic circuit rotating parts, and stator/rotor bodies, etc., and can solve complex winding processes, long processing cycles, and low production efficiency of permanent magnet motors. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

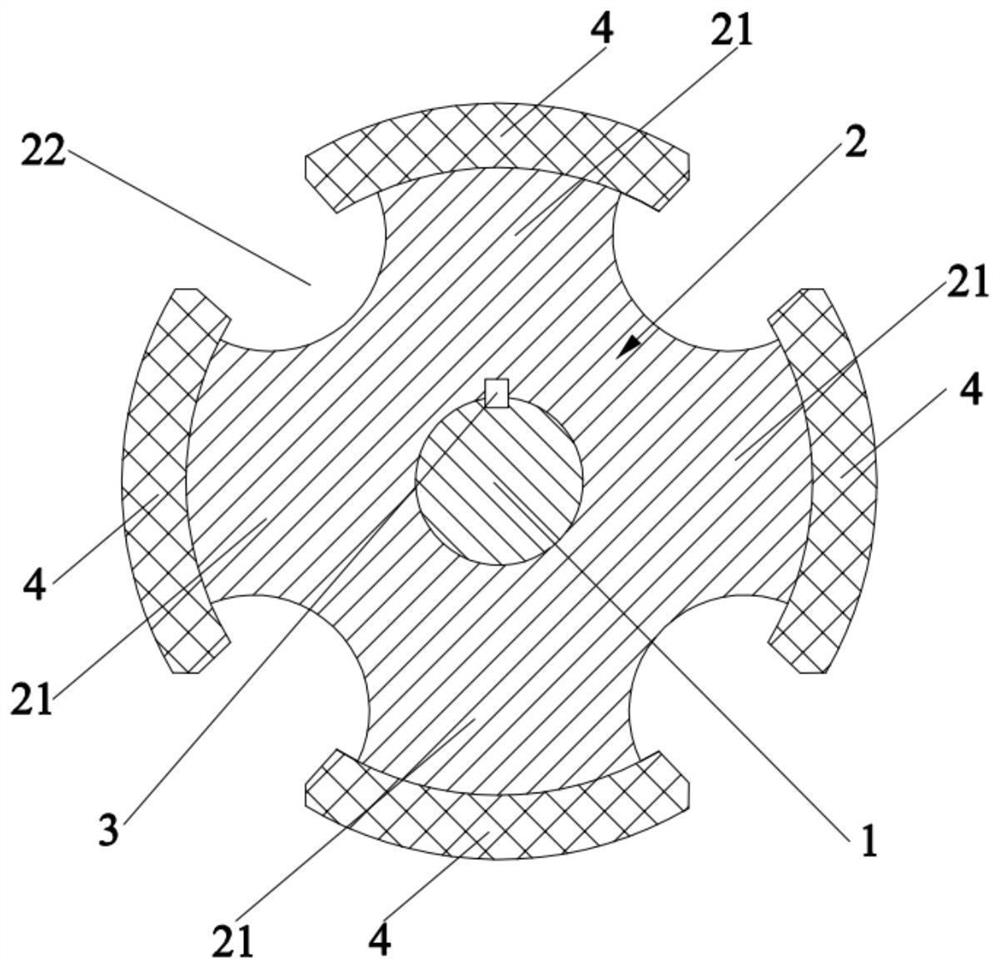

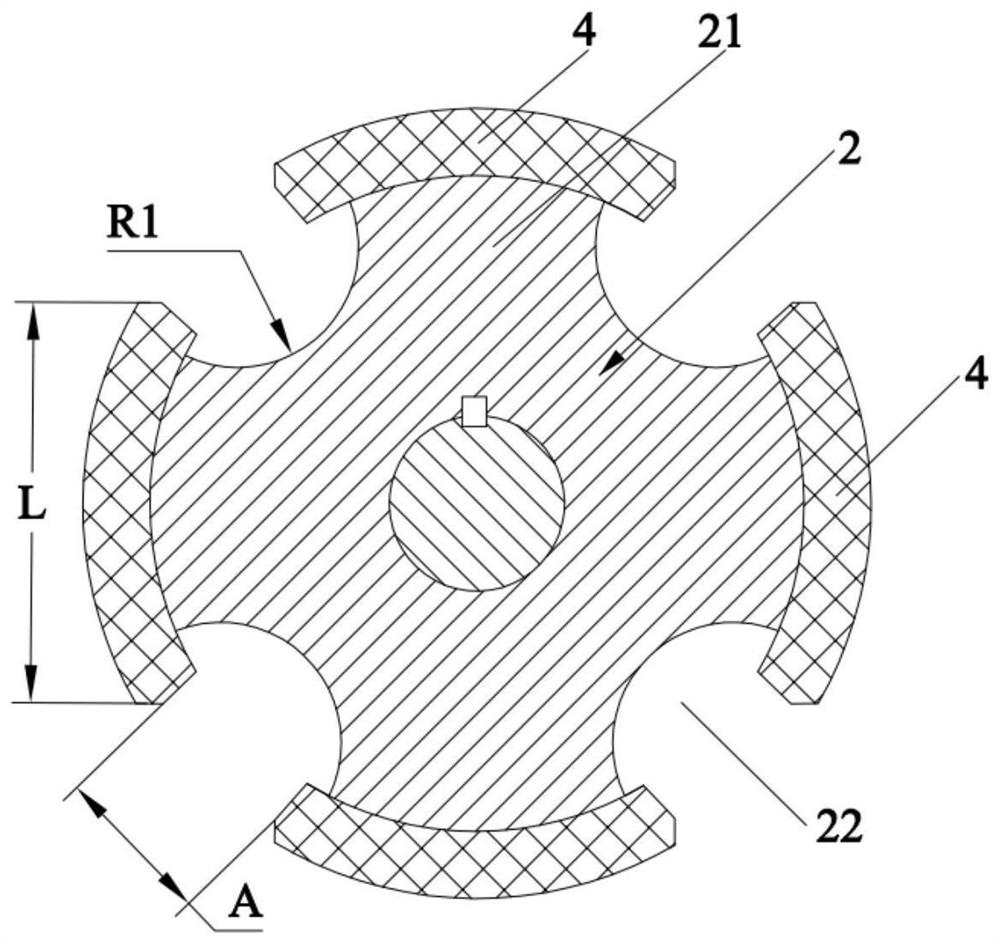

[0042] This embodiment provides a permanent magnet motor rotor, which includes a rotating shaft 1 , a silicon steel sheet group 2 and a plurality of magnetic tiles 4 .

[0043] Such as figure 1 As shown, the silicon steel sheet group 2 is sleeved on the rotating shaft 1 . Specifically, a shaft hole is provided at the center of the silicon steel sheet group 2, and the silicon steel sheet group 2 is sheathed on the rotating shaft 1 through the shaft hole. Further, key grooves are provided in the shaft hole and on the rotating shaft 1 respectively, and the fixing key 3 is installed in the key groove to realize the fixing between the silicon steel sheet group 2 and the rotating shaft 1 . The structure of the fixed key 3 is a prior art, and will not be repeated here.

[0044] refer to figure 1 and image 3 A plurality of magnetic tiles 4 are fixed outside the silicon steel sheet group 2 at intervals along the circumferential direction of the silicon steel sheet group 2 (that is...

Embodiment 2

[0070] The present embodiment provides a kind of processing method of permanent magnet motor rotor, and it comprises the following steps:

[0071] (1) Set the silicon steel sheet group 2 on the rotating shaft 1 , and realize the fixing between the silicon steel sheet group 2 and the rotating shaft 1 through the fixing key 3 .

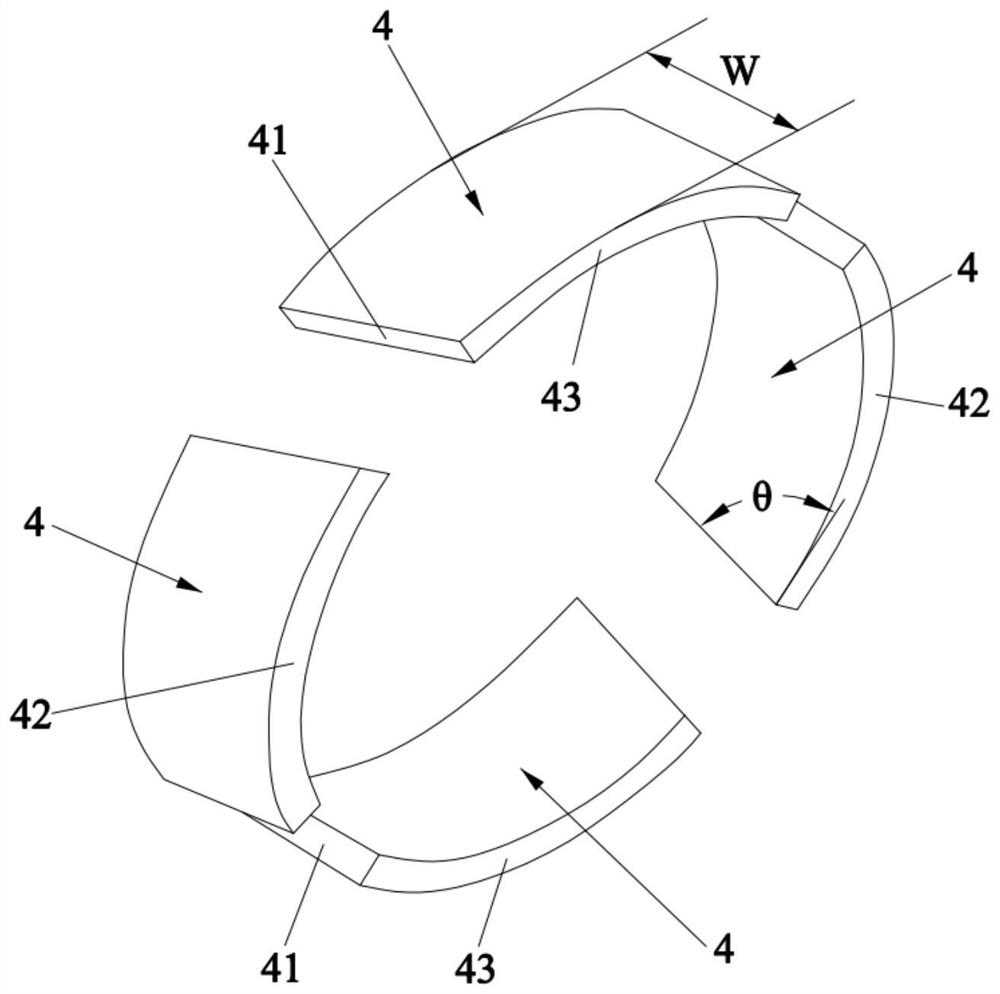

[0072] (2) A plurality of magnetic tiles 4 corresponding to the number of poles of the permanent magnet motor are subjected to chamfering processing. During chamfering, the two ends of each magnetic tile 4 in the circumferential direction are respectively inclined relative to the axial direction of the magnetic tile 4 and the direction of inclination is opposite. , to form the chamfered surface 41 .

[0073] In fact, the processing process of the traditional magnetic tile is as follows: firstly, the width, length and bow height of the blank of the magnetic tile are ground, then automatic internal and external chamfering, rough and fine grinding of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com