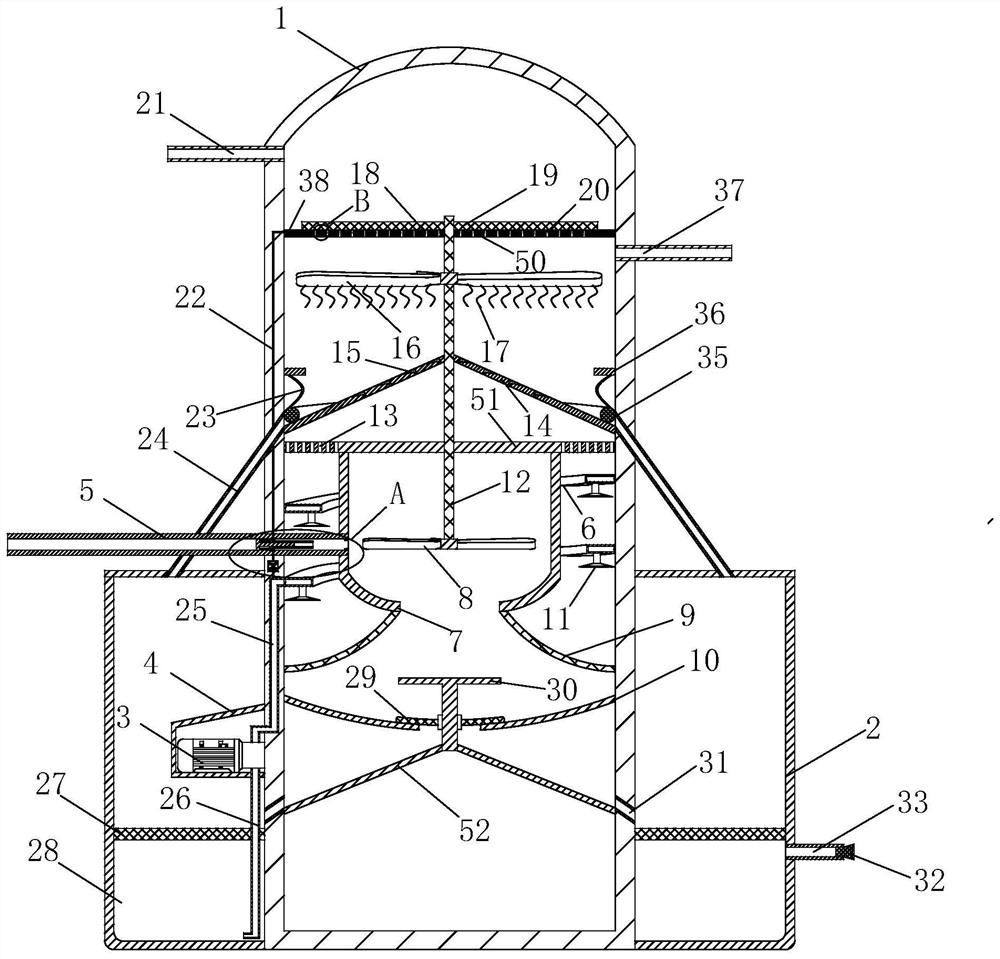

Combustion flue gas desulfurization and denitrification tower

A technology for desulfurization, denitrification, and combustion of flue gas. It is applied in gas treatment, filtration circuits, and dispersed particle filtration. It can solve the problems of wasting reaction solution, troublesome cleaning or maintenance, and affecting the effect of flue gas purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

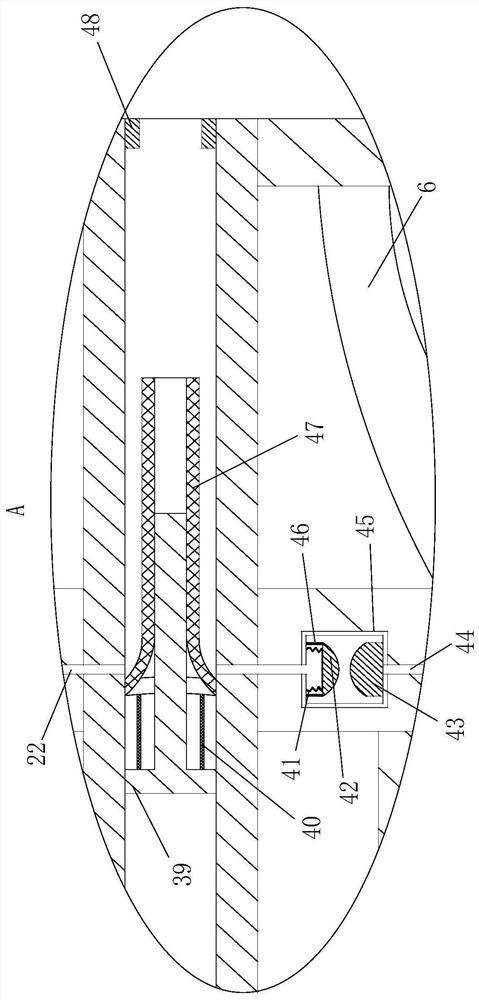

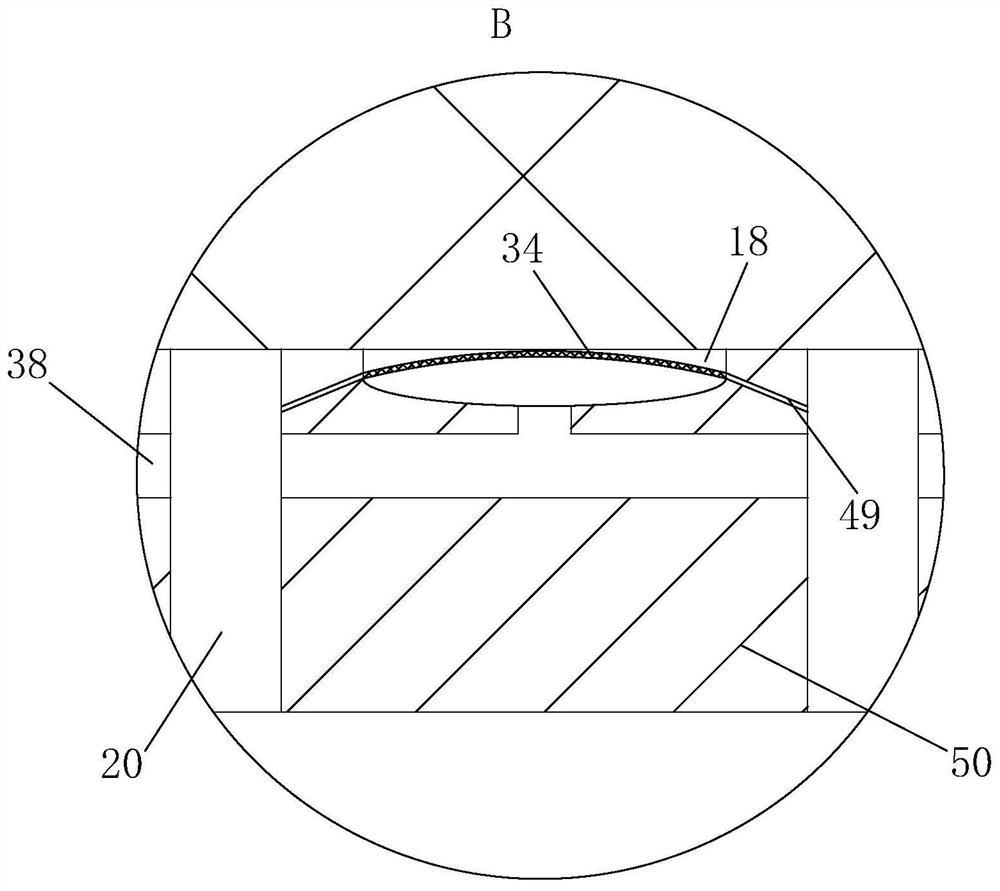

[0027] As an embodiment of the present invention, an arc-shaped plate 10 is fixedly connected to the side wall of the tower body 1; the arc-shaped plate 10 is located below the first filter plate 9; the side wall of the tower body 1 is fixedly connected There is a spiral tube 6; the spiral tube 6 is located above the first filter plate 9 and surrounds the outer surface of the dust removal chamber 7; the surface of the spiral tube 6 is fixedly connected with uniformly arranged spray heads 11; the spray The head 11 is connected to the inner space design of the spiral pipe 6; the left side wall of the tower body 1 is fixedly connected with a water outlet pipe 25; the top of the water outlet pipe 25 is connected to the inner space design of the spiral pipe 6; the interior of the collection cavity 2 A trapezoidal groove 4 is opened; a water pump 3 is fixedly connected inside the trapezoidal groove 4; the bottom of the water outlet pipe 25 is fixedly connected with the water pump 3; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com