Stamping and bending device for steel products

A technology for stamping, bending and steel products, which is applied in the direction of feeding device, positioning device, storage device, etc., which can solve the problems of inconvenient promotion and implementation, inaccurate stamping and bending, and unstable positioning of the stamping device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

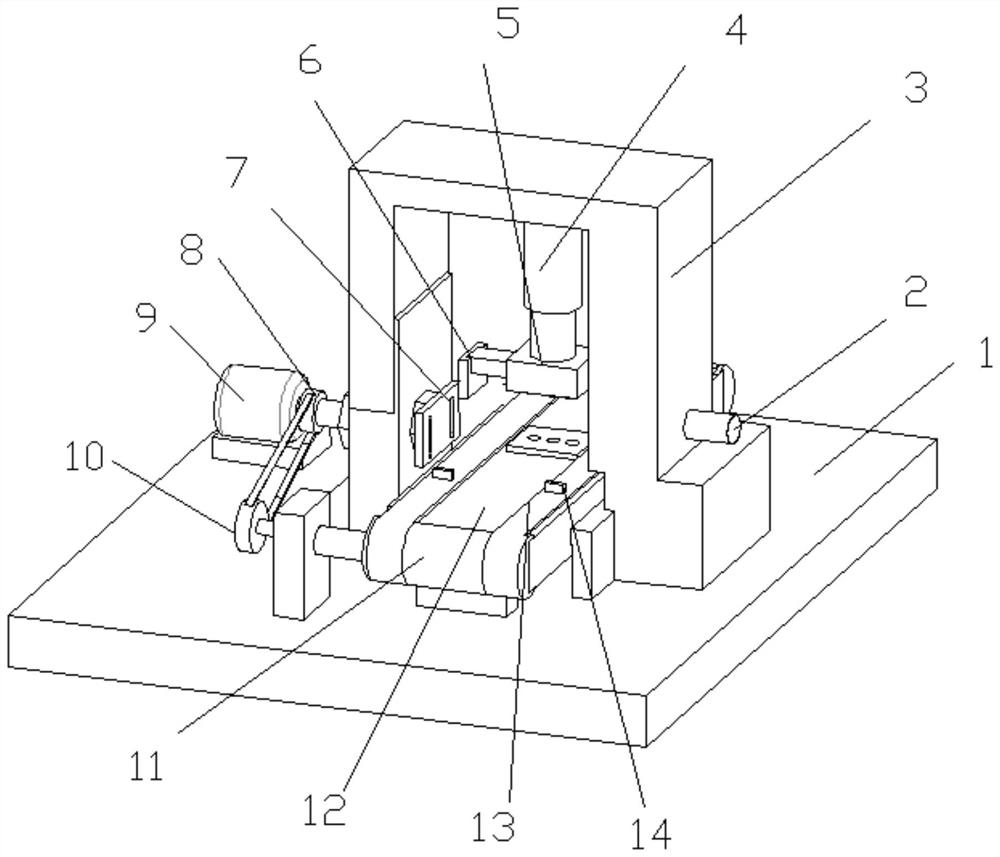

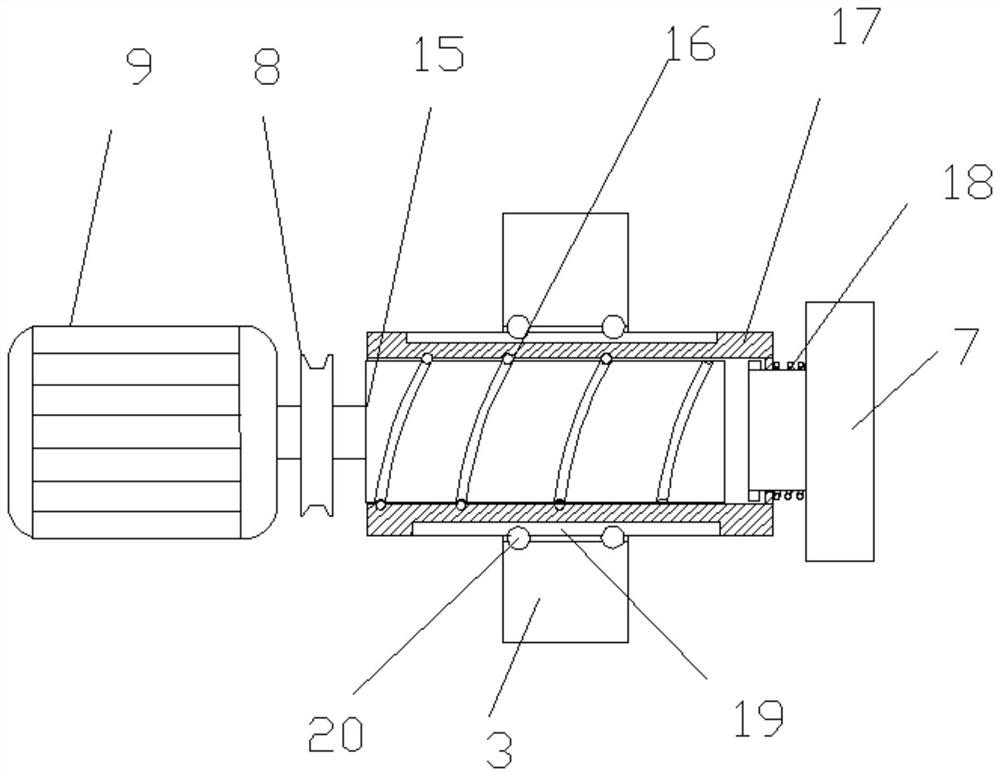

[0026] see Figure 1-3 , a stamping and bending device for steel products, including a bottom plate 1, a workbench 12 and stamping parts 5. A mounting frame 3 is fixedly arranged on the upper surface of the bottom plate 1, and the mounting frame 3 is an inverted U-shaped structure. The inner top of the installation frame 3 is fixedly connected to the top of the hydraulic rod 4, the bottom of the hydraulic rod 4 is fixedly connected to the stamping part 5, and the end of the stamping part 5 is fixedly connected to the bent pressing part 6. Under the action of the hydraulic rod 4, the hydraulic pressure The rod 4 is elongated, so that the punching part 5 and the bending part 6 are lowered, thereby completing the punching and bending. The inner side wall of the mounting bracket 3 is provided with a vertical sliding groove 25, and the end of the stamping part 5 is fixedly connected with a sliding rod 23, and the end of the sliding rod 23 is slidably nested in the inside of the sl...

Embodiment 2

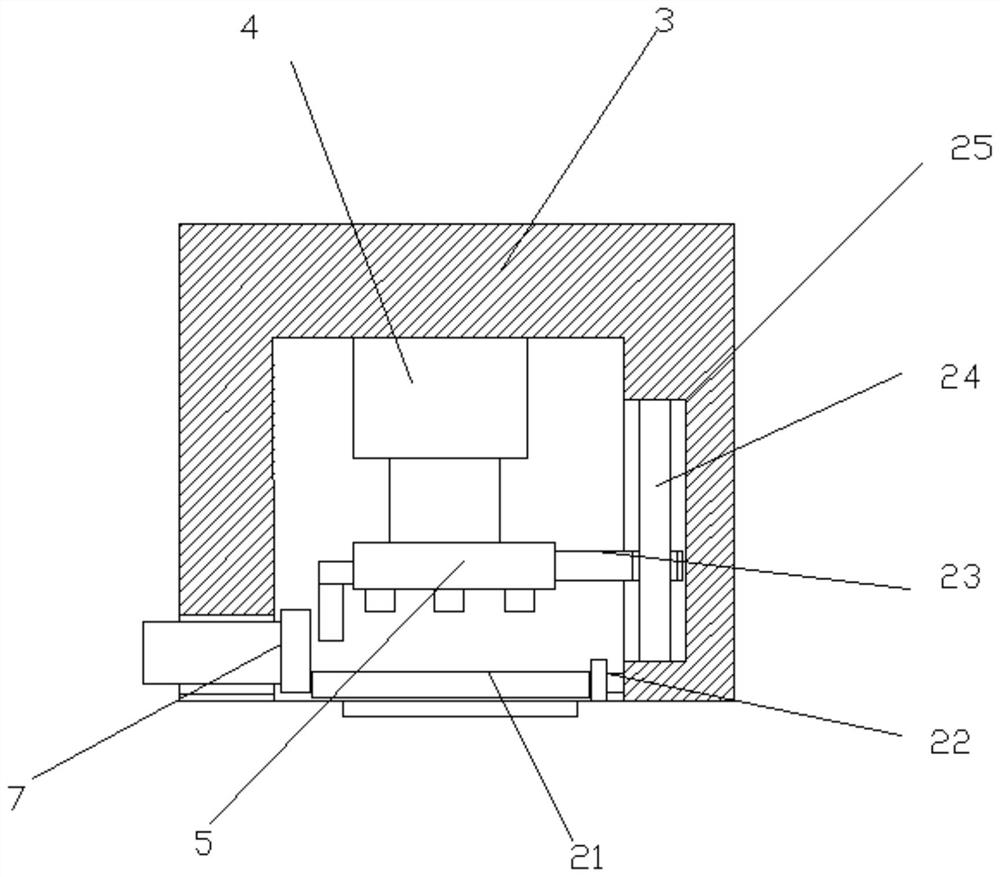

[0031] see Figure 4 , on the basis of Embodiment 1, the opposite side of the positioning plate 7 is provided with a positioning top plate 22 on the inner wall of the mounting frame 3, and under the action of the positioning plate 7 and the positioning top plate 22, the positioning top plate 22 and the positioning plate 7 stand on the steel product 21, so that the location of the steel product 21 is accurate, and it is convenient to improve the stamping of the steel product 21 more accurately. The positioning top plate 22 is connected with an adjustment member 2, and the position of the positioning top plate 22 can be adjusted through the adjustment member 2, thereby adjusting the bending position and improving the applicability of the device. The adjusting part 2 includes a screw mandrel 26 and a rotating sleeve 27. The positioning top plate 22 is fixedly connected to the end of the screw mandrel 26. The screw mandrel 26 slides and nests inside the screw mandrel 26. The screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com