Rotating device for laser cutting

A rotating device and laser cutting technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of single or two functions and low automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

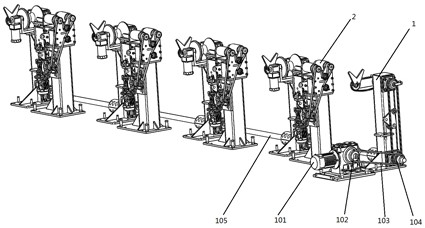

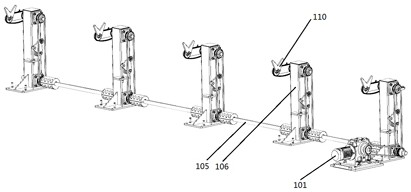

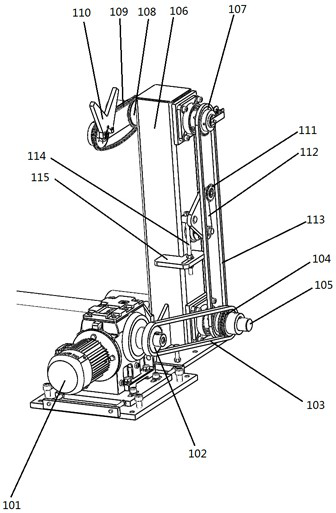

[0031] Such as Figure 1-7 As shown, the purpose of the present invention is achieved in this way: the rotating device for laser cutting includes a plurality of profile turning mechanisms 1061 distributed in rows and the profile rotating mechanism 2; the profile rotating mechanism 2 moves the profile to one side, and realizes the The rotation of the profile; the profile rotating mechanism 2 includes a rotating base 201, the side of the rotating base 201 is provided with a rotating motor 202, the output end of the rotating motor 202 is provided with a drive wheel 203, and the upper end of the rotating base 201 is provided with a pair of lugs 206, the ear Roller 1 213 and roller 2 214 are rotatably arranged between plates 206, and the rotating motor 202 drives roller 1 213 and roller 2 214 to rotate, and the right ends of roller 1 213 and roller 2 214 are fixedly provided with driven wheel 1 215 and driven wheel 2 208 The middle part of the right side of the ear plate 206 is rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com