All-electric injection device driven by planetary gears

A technology of injection device and planetary gear, applied in the field of injection device driven by planetary gear, can solve the problems of downtime of injection seat, wear of lead screw, difficulty in adjusting power unity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

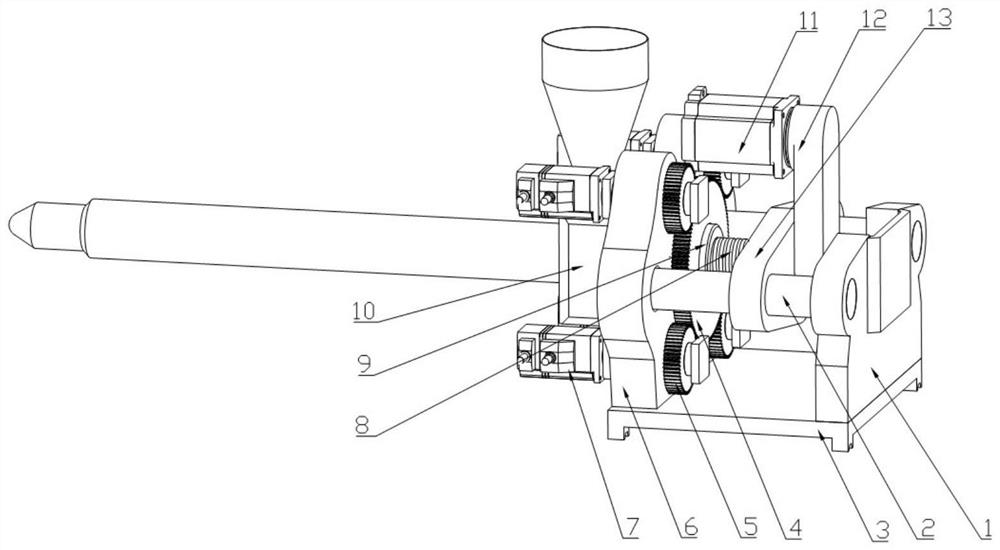

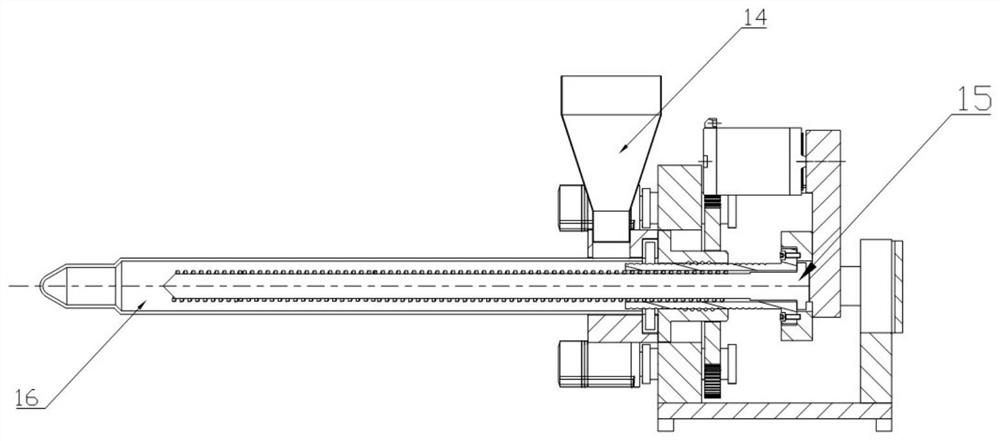

[0016] The present invention will be further described below in conjunction with accompanying drawing.

[0017] A planetary gear driven fully electric injection unit such as figure 1 As shown, the injection front plate (6) and the injection rear plate (1) are installed on the bottom plate (3), and the two are connected by two tie rods (2), and the central gear (4) is connected to the screw nut through the bushing structure (9) Install on the injection front plate (6). The driving motor (7) drives the motor driving gear (5) to rotate through the gear shaft structure, and the four motor driving gears (5) mesh with the central gear (4) and are evenly distributed around it. The four driving motors (7) are respectively The power is transmitted to the four drive gears (5), and then the central gear (4) is driven to rotate, and the lead screw nut (9) is driven to rotate after the central gear (4) concentrates the power. The plasticizing motor (11) is installed on the plasticizing g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com