Thermal print head and method of making the same

A technology of a thermal print head and a manufacturing method, which is applied in the printing field, can solve problems such as low thermal conductivity, reduce the heat conduction efficiency of a heating element to a printing medium, and improve durability and reliability, increase heat conduction efficiency, and practicability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

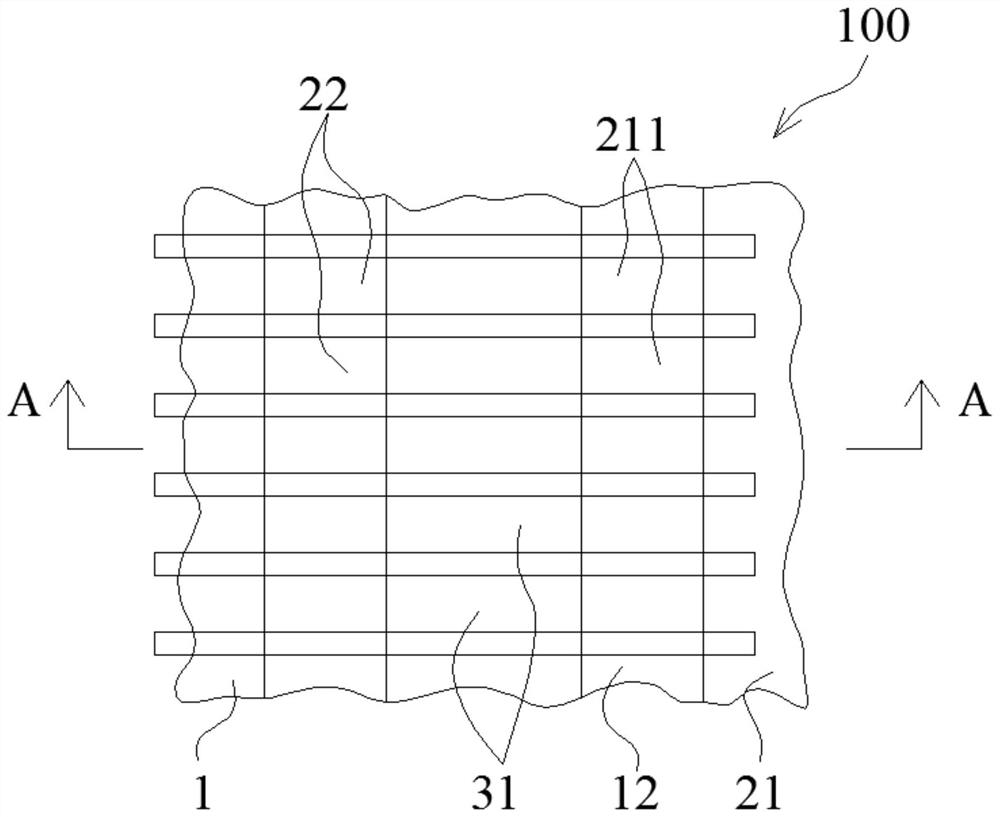

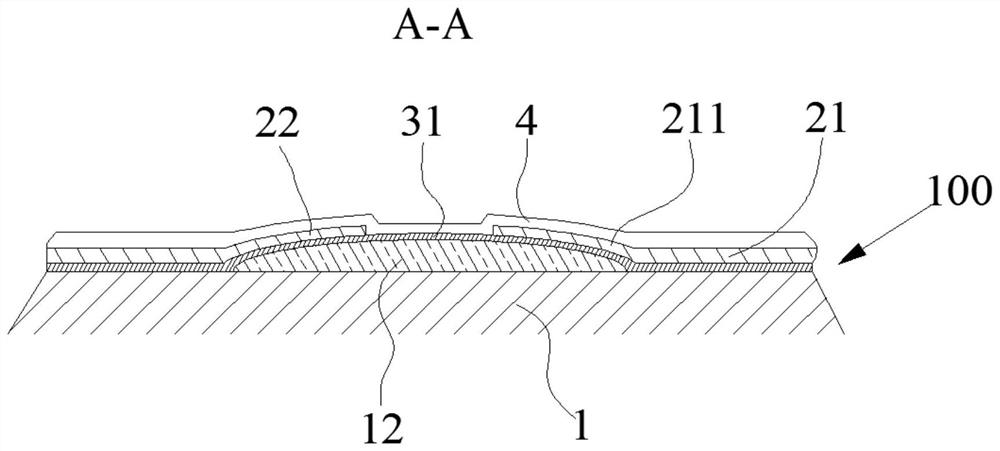

[0059] Figure 5 A schematic structural diagram of the thermal print head according to the first embodiment of the present invention is shown; Image 6 show Figure 5 The thermal printhead shown is a cross-sectional view along C-C. Specifically, the thermal print head 300 includes an insulating substrate 1 , an electrode layer 2 , a resistance layer 3 , and a protective layer 4 . The thermal print head 300 is assembled in a thermal transfer apparatus (not shown in the figure) for printing thermal photos, images, and the like.

[0060] In this embodiment, the insulating substrate 1 is made of alumina ceramics. The thermal print head 300 further includes a heat storage layer 12 formed on the top surface of the insulating substrate 1 . The heat storage layer 12 can be a glass glaze made of screen-printed amorphous glass paste and sintered, such as Image 6 shown.

[0061] The top surface of the heat storage layer 12 is provided with a first groove 121 and a second groove 12...

no. 2 example

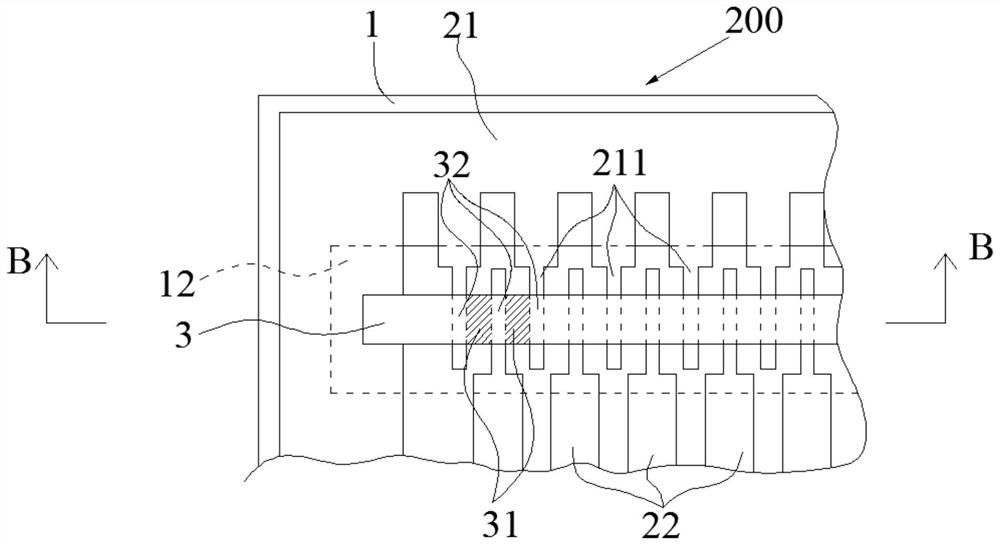

[0087] like Figure 13 and Figure 14 shown, Figure 13 A schematic structural diagram of the thermal print head according to the second embodiment of the present invention is shown; Figure 14 show Figure 13 A cross-sectional view of the thermal print head in the direction of D-D; specifically, the thermal print head 300 includes an insulating substrate 1 , an electrode layer 2 , a resistance layer 3 , and a protective layer 4 . The thermal print head 300 is assembled in a thermal transfer apparatus, and prints thermal photos, images, and the like.

[0088] In this embodiment, the insulating substrate 1 is formed of alumina ceramics. The thermal print head 300 further includes a heat storage layer 12 formed on the top surface of the insulating substrate 1 . The heat storage layer 12 can be a glass glaze made of screen-printed amorphous glass paste and sintered, such as Figure 14 shown.

[0089] The top surface of the heat storage layer 12 is provided with a first gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com