Adjustable battery pack locking mechanism suitable for hoisting type battery replacing vehicle

A locking mechanism and adjustable technology, applied in electric vehicles, vehicle energy storage, vehicle components, etc., can solve problems such as difficult maintenance, inconsistent thickness, and frequent maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

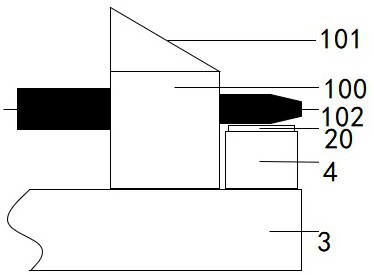

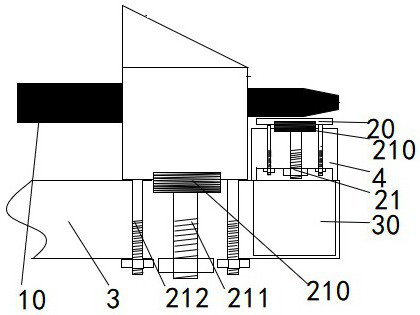

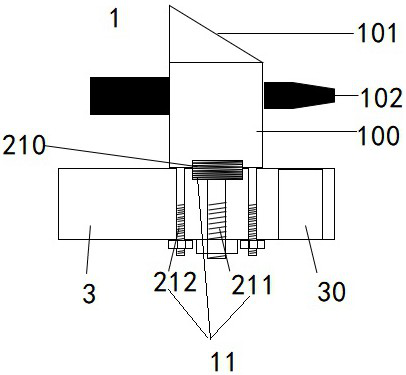

[0049] like figure 1 , the existing solution provides a battery pack locking mechanism suitable for hoisting battery exchange vehicles, using a fixed pressure plate, the locking pressure plate is fixed on the bottom support of the battery pack frame 4 locking pressure plate with bolts, and the locking pressure plate bottom support It is connected with the battery pack frame 4 by welding. Due to the deformation of the battery pack frame 4 or the battery pack bracket 3, the lock can not be opened, locked, or the gap is too large due to the change of the gap between the lock and the lock plate. , can only be adjusted by changing the thickness of the locking platen. Each battery pack has 6-8 locking platens. The thickness of each platen is inconsistent due to deformation, resulting in frequent maintenance and many spare parts models; The lock assembly and the battery pack bracket 3 are connected by welding, and the lock cannot be opened due to the failure of the lock mechanism, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com