Material capsule with dynamic combined material pipe

A technology combining material tubes and capsules, which is applied in the direction of containers, packaging, flexible containers, etc., and can solve the problems of low efficiency of powder material collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

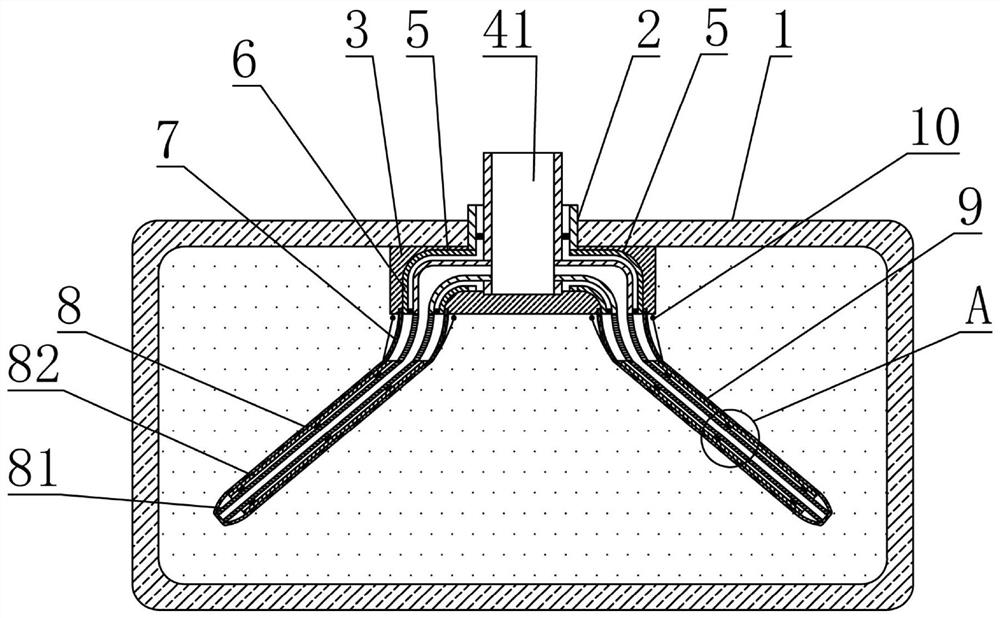

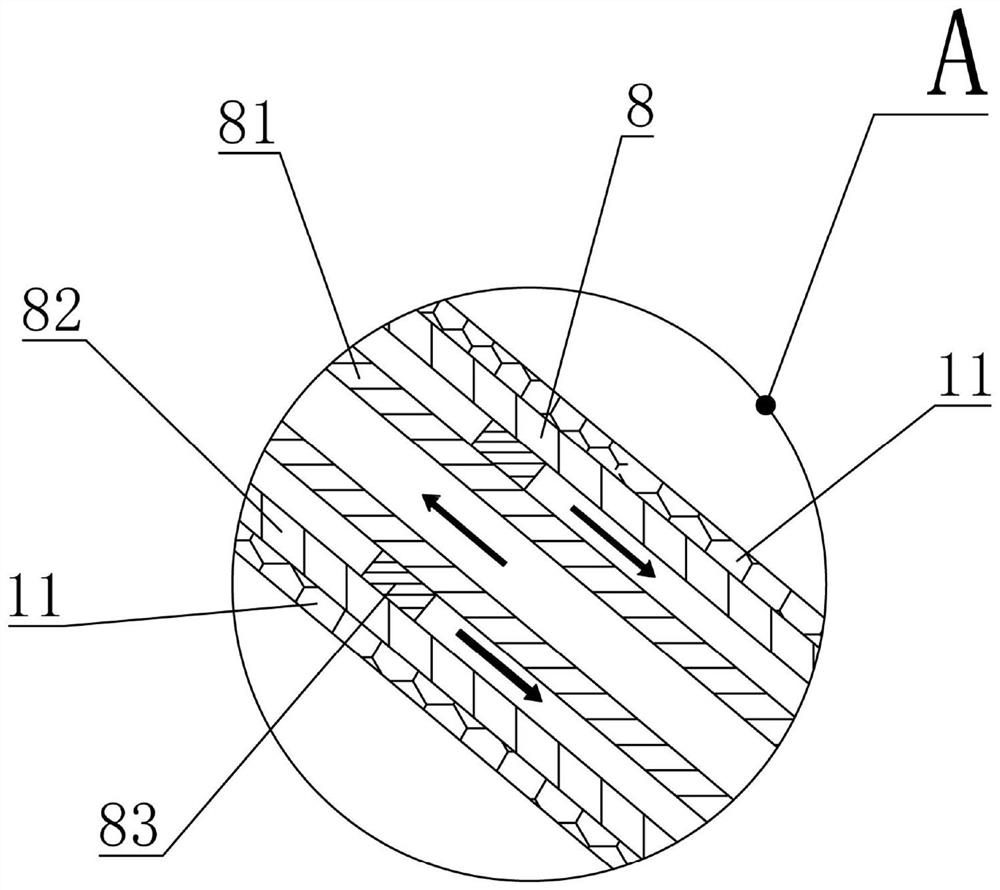

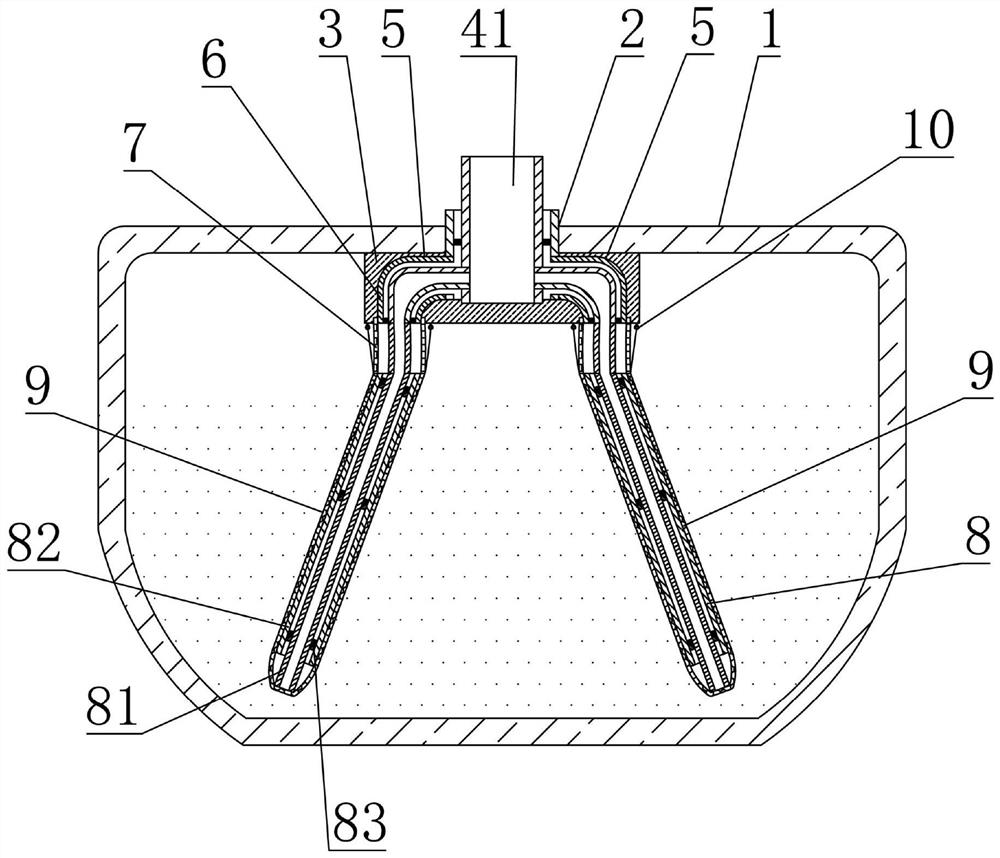

[0033] refer to Figure 1-3 , Figure 8-10 , a material capsule with a dynamic combination material tube, including a capsule body 1, the capsule body 1 is made of polymer wear-resistant rubber material, which has good wear resistance and elastic recovery ability, and is set at the center of the top of the capsule body 1 There is a feed port 2 for feeding and unloading. The material capsule is designed with an integrated structure. Through the combination of the combined distribution tube and the auxiliary moving device installed in the capsule body, the material residue at the inner corner of the capsule is avoided. Through rubber elastic recovery and spring elastic recovery, the effect of material tube suction moving closer to the middle is realized, which greatly improves the working efficiency of the material suction link, and at the same time improves the cleanliness of the material capsule discharge, further improving the quality of the material. Capsules are practical ...

Embodiment 2

[0038] refer to Figure 4-10 , a material capsule with a dynamic combination material tube, including a capsule body 1, the capsule body 1 is made of polymer wear-resistant rubber material, which has good wear resistance and elastic recovery ability, and is set at the center of the top of the capsule body 1 There is a feed port 2 for feeding and unloading. The material capsule is designed with an integrated structure. Through the combination of the combined distribution tube and the auxiliary moving device installed in the capsule body, the material residue at the inner corner of the capsule is avoided. Through rubber elastic recovery and spring elastic recovery, the effect of material tube suction moving closer to the middle is realized, which greatly improves the working efficiency of the material suction link, and at the same time improves the cleanliness of the material capsule discharge, further improving the quality of the material. Capsules are practical and highly effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com