Sodium cyclamate production process and device

A production process and production device technology, applied in the fields of food science, application, amide sulfate preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

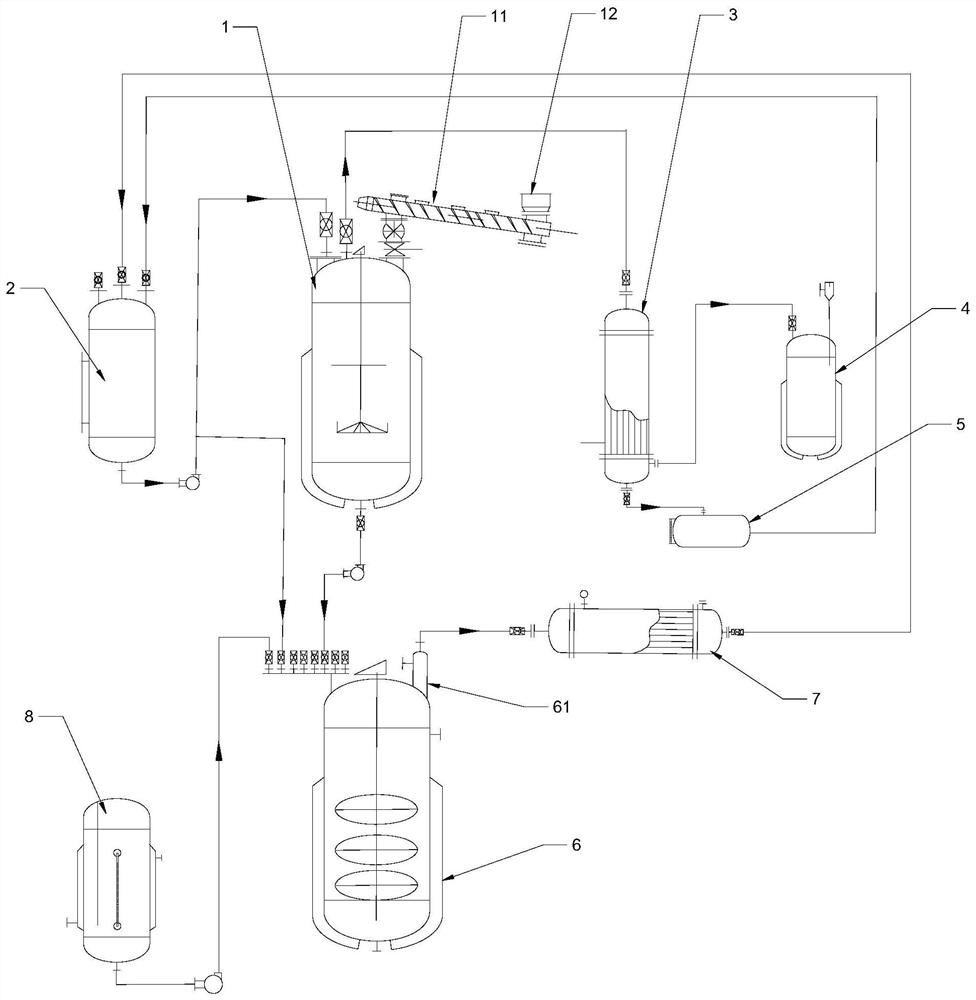

[0021] Sulfamic acid (3975kg, 40.9kmol) was added to the neutralization tank 1, and then in the reactor 6, dilute cyclohexylamine with a concentration of 40% was added dropwise until the pH of the reaction solution was 6.8, and the reaction solution was transferred to the reactor 6 Inside, be heated to 50 ℃ and concentrate reaction solution, be concentrated to the material and become thick paste; Then in reactor 6, drip the concentrated cyclohexylamine (40.9kmol) that concentration is 90% to carry out reaction, and reaction temperature is 60 ℃, and reaction Process steam pressure is controlled at 0.1MPa, and NaOH (1636kg, 40.9kmol) is added in reactor 6 after the amine outlet 61 that is provided with on reactor 6 turns cold after 4 hours, then in reactor 6, adding concentration is 40% dilute Cyclohexylamine (15.9m 3 ), use dilute cyclohexylamine to take out the cyclohexylamine decomposed by the reaction, and the reaction is completed and purified, and the yield is 95%.

Embodiment 2

[0023] Sulfamic acid (4025kg, 41.5kmol) was added to the neutralization tank 1, and then in the reactor 6, a concentration of 50% dilute cyclohexylamine was added dropwise until the pH value of the reaction solution was 6.8, and the reaction solution was transferred to the reactor 6 Inside, be heated to 90 DEG C and concentrate reaction liquid, be concentrated to material and become thick paste; Then dropwise in reactor 6, concentration is the concentrated cyclohexylamine (43.6kmol) of 95% to react, and reaction temperature is 100 DEG C, reaction Process steam pressure is controlled at 0.3MPa, and NaOH (1709kg, 42.7kmol) is added in reactor 6 after the amine outlet 61 that is set on reactor 6 turns cold for 5 hours, then dilute cyclohexylamine (16.1 kmol) is added in reactor 6 m3), use dilute cyclohexylamine to take out the cyclohexylamine decomposed by the reaction, and the reaction is completed and purified, and the yield is 99%.

Embodiment 3

[0025] Sulfamic acid (4025kg, 41.5kmol) was added to the neutralization tank 1, and then in the reactor 6, dilute cyclohexylamine with a concentration of 50% was added dropwise until the pH of the reaction solution was 7.0, and the reaction solution was transferred to the reactor 6 Inside, be heated to 120 DEG C and concentrate reaction liquid, be concentrated to material and become sticky paste; Then dropwise in reactor 6, concentration is the thick cyclohexylamine (45.6kmol) of 99% to react, and reaction temperature is 150 DEG C, reaction Process steam pressure is controlled at 0.5MPa, and NaOH (1741kg, 43.5kmol) is added in reactor 6 after the amine outlet 61 that is set on reactor 6 turns cold 6 hours, then adds dilute cyclohexylamine (16.9 kmol) in reactor 6 m 3 ), with dilute cyclohexylamine to take out the cyclohexylamine decomposed by the reaction, the reaction is completed and purified, and the yield is 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com