Special-shaped sealing ring for vacuum milling clamp for skin parts and use method of special-shaped sealing ring

A special-shaped sealing ring, vacuum technology, used in the sealing of the engine, metal processing mechanical parts, clamping and other directions, can solve the inconvenient installation and operation, the parts and the fixture surface are not tightly fitted, and the rubber shaft interface is prone to air leakage. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

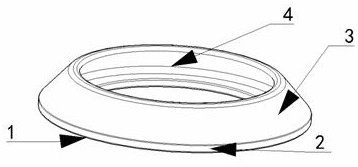

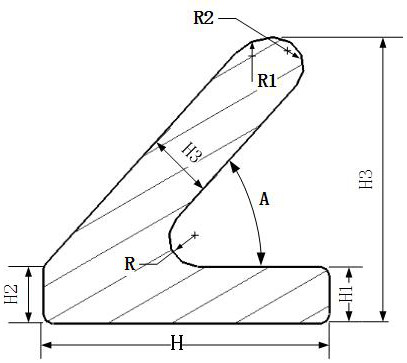

[0032] A special-shaped sealing ring for vacuum milling fixtures for skin parts, which relates to the technical field of vacuum milling fixtures in aircraft manufacturing, including a bottom structure 1, a boss structure 2 and a side structure 3, the boss structure 2 is The transition structure between the bottom structure 1 and the side structure 3, one end of the side structure 3 is connected to the boss structure 2; the other end of the side structure 3 is suspended and chamfered, the bottom structure 1, the boss structure 2 and the side The inner surface of the structure 3 forms a middle hollow structure 4, and the inner side of the side structure 3 and the inner side of the bottom structure 1 form an angle of 48°±2°.

[0033] This embodiment is the most basic implementation mode. The obtained ring-shaped special-shaped sealing ring has a cross-sectional shape in the shape of "∠", which is easy to install and is not easy to leak when it is used for sealing of skin parts 6 v...

Embodiment 2

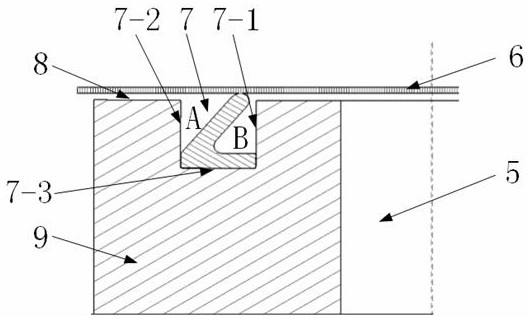

[0035] This embodiment takes the installation condition of a special-shaped sealing ring in the sealing groove 7 of a vacuum milling fixture of a skin part as an example, and the structure of the special-shaped sealing ring refers to figure 1 Shown:

[0036] The shape of the special-shaped sealing ring is circular, and the cross-sectional shape of the special-shaped sealing ring is in the shape of "∠". It specifically includes a bottom structure 1, a boss structure 2 and a side structure 3. The boss structure 2 is a transition structure between the bottom structure 1 and the side structure 3. One end of the side structure 3 is connected to the boss structure 2; The other end of the structure 3 is suspended and has a certain chamfer. The inner surface of the bottom structure 1, the boss structure 2 and the side structure 3 forms an intermediate hollow structure 4, and the inside of the side structure 3 is 48°± from the inside of the bottom structure 1. 2°.

[0037] Further, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com