Engine powered fork lift truck self-diagnosis control system

A control system, a technology for internal combustion forklifts, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc., to solve problems such as failure to detect faults, lack of professional tools for bus diagnosis, and inability to be implemented by personnel with bus technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

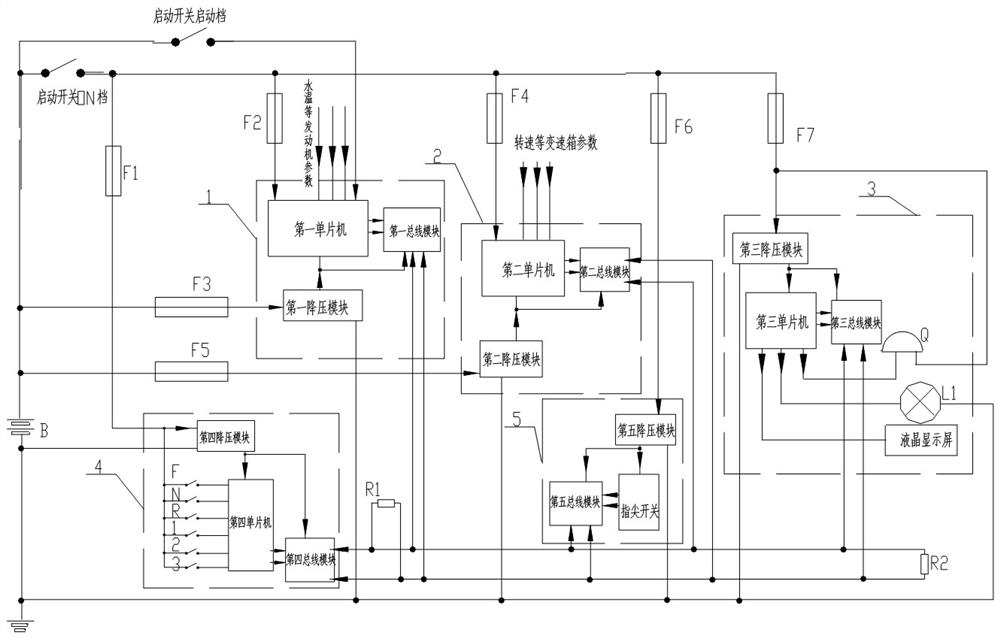

[0025] Such as figure 1 As shown, a self-diagnostic control system for an internal combustion forklift, including:

[0026] Battery B is used to start the power supply of the forklift. Before the forklift is started, it supplies power to the parts of the whole machine, and when the generator fails to supply power after the whole machine is started, it supplies power to the electrical components;

[0027] The start switch is divided into ON gear and start gear, the start ON gear cuts off or connects the power supply of electrical components, and the start gear starts the forklift;

[0028] Engine controller ECU 1 is used to control the engine. When the engine is running, the engine controller ECU 1 collects water temperature sensor parameters, fuel sensor parameters, start ON gear parameters, engine oil pressure sensor signals and camshaft speed signals for calculation, and calculates The result is converted into a control signal to control the engine, and the engine controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com